20 Gear Drive, Plymouth Ind. Park, Terryville, CT 06786

Tel: (860) 585-1254 Fax: (860) 584-1973 http://www.amci.com 3

Table of Contents

General Information

Important User Information ..................... 2

Standard Warranty ................................... 2

Returns Policy .......................................... 2

24 Hour Technical Support Number ........ 2

We Want Your Feedback ......................... 2

About this Manual

Audience .................................................. 5

Applicable Units ...................................... 5

Trademark Notices ................................... 5

Revision Record ....................................... 5

Revision History ............................ 5

Navigating this Manual ............................ 5

Manual Conventions ................................ 6

Where To Go From Here ......................... 6

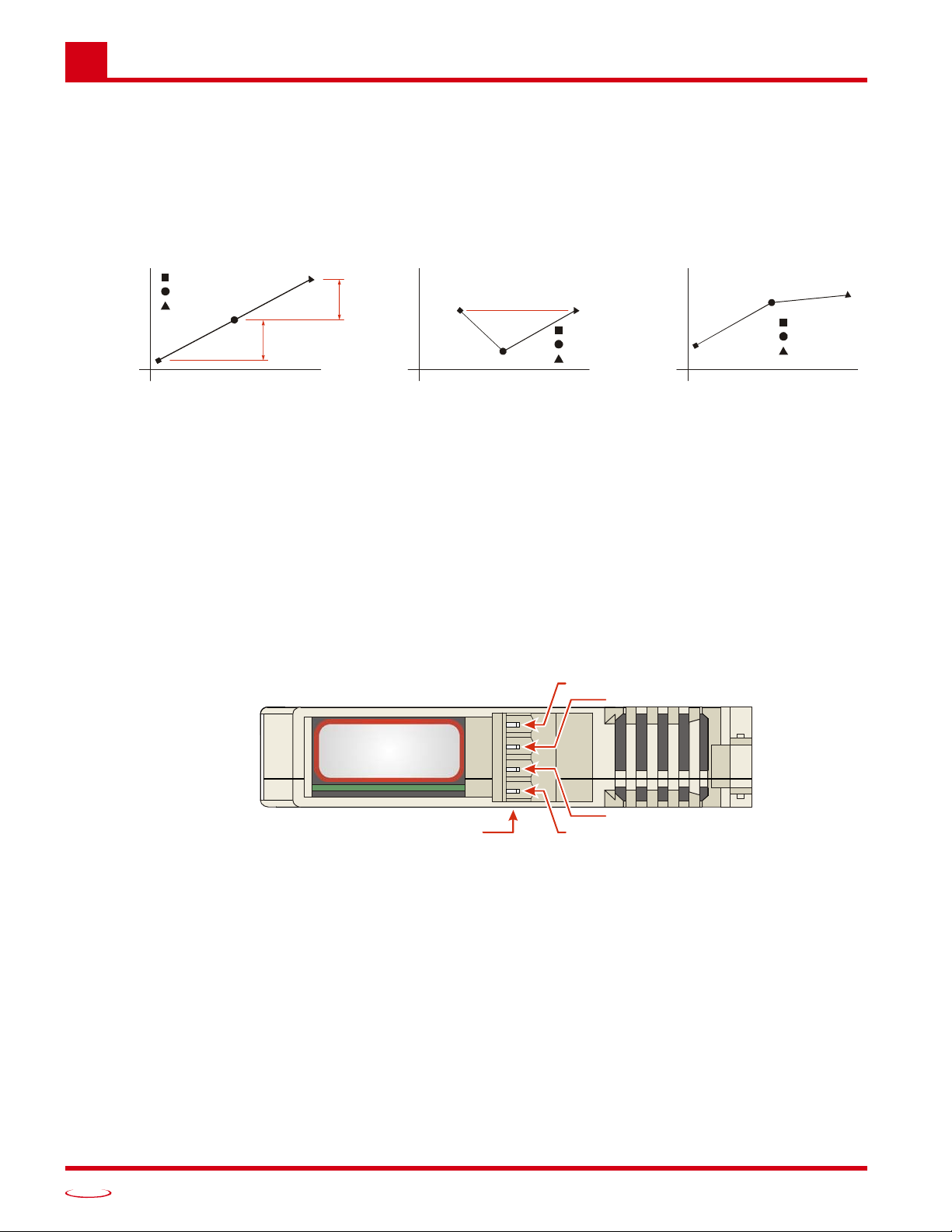

Chapter 1: Introduction to the ANR2

AnyNET-I/O ............................................ 7

The ANR2 ................................................ 7

LVDT Interface ............................. 8

Master/Slave Excitation Mode ...... 8

ANR2 Programmable Parameters ............ 9

Module Parameters ........................ 9

Sensor Parameters ......................... 9

Position Output ........................................ 9

Power Connector ...................................... 10

I/O Connector .......................................... 11

Front Panel ............................................... 11

Address Settings ............................ 11

Status LED’s .................................. 12

Module States 12

Channel States 12

Excitation Mode Jumper ................ 13

Specifications ........................................... 13

Chapter 2: Operating Modes

Available Modes ...................................... 15

Calibration Mode ........................... 15

Configuration Mode ...................... 15

Alignment Mode ............................ 16

Measurement Mode ....................... 16

Status Bits ................................................ 16

Module Status Bits ........................ 16

Channel Status Bits ........................ 16

Power Up Behavior .................................. 17

Switching Modes During Normal Operation 17

Chapter 3: Installing the ANR2

Safe Handling Guidelines ........................ 19

Prevent Electrostatic Damage ....... 19

Prevent Debris From Entering

the Module .................................. 19

Remove Power Before Servicing

in a Hazardous Environment ...... 19

Mounting .................................................. 19

Dimensions ................................... 19

Installing IC-5 Connectors ............ 20

Mounting the ANR2 Module ........ 20

Addressing ................................................ 20

Power Connector ...................................... 21

I/O Connector Pin Out ............................. 21

Sensor Wiring ........................................... 22

Half Bridge ................................... 22

3-Wire Sensor ............................... 22

4-Wire Sensor ............................... 23

5-Wire Sensor ............................... 23

Differential Wiring ............. 23

Ratiometric Wiring ............. 24

6-Wire Sensor ............................... 25

Differential Wiring ............. 25

Ratiometric Wiring ............. 26

Extending the Transducer Cable .............. 27

Half Bridge Sensor ........................ 27

3-Wire Sensor ............................... 27

5-Wire Differential ....................... 28

5-Wire Ratiometric ....................... 29

6-Wire Differential ....................... 29

6-Wire Ratiometric ....................... 30

Avoiding Ground Loops When

Extending the Sensor Cable ........ 30

Excitation Slave Mode ............................. 31

Excitation Mode Jumper ............... 31

SyncOut/SyncIn Wiring ................ 31

Chapter 4: AMCI Net Configurator

Software

ANR2 Configuration Screen .................... 33

ANR2 Alignment Screen ......................... 34

ANR2 Measurement Screen ..................... 35

Chapter 5: Network Input Data

Format

Network Input Data .................................. 37

32 Bit Sign/Magnitude Format ..... 37