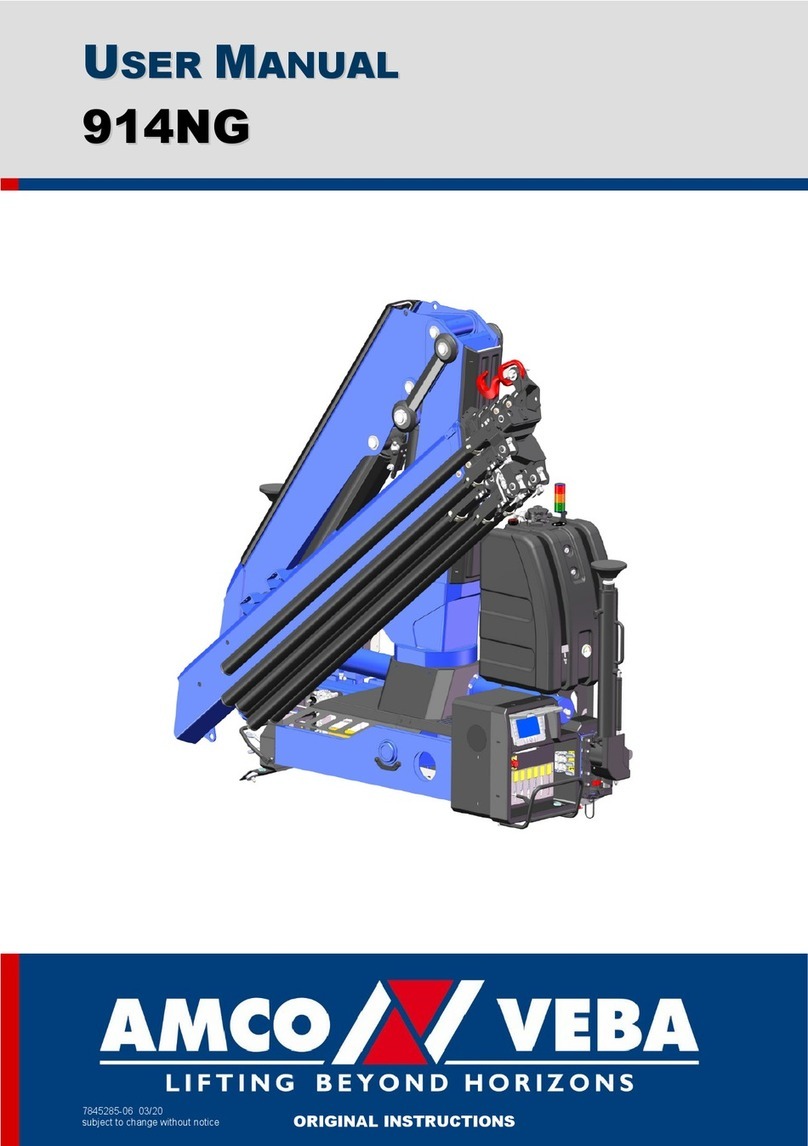

USER MANUAL

811NG

INDEX

subject to change without notice

AWARNINGS ........................................................................................................................ A.1

A.1 PERSONAL PROTECTIVE EQUIPMENT.................................................................................................A.1

A.2 MECHANICAL HAZARDS ........................................................................................................................A.2

A.2.1 STRUCTURAL RESISTANCE................................................................................................................... A.2

A.2.2 CRUSHING HAZARD................................................................................................................................ A.4

A.2.3 CUTTING HAZARD ................................................................................................................................... A.5

A.2.4 IMPACT HAZARD ..................................................................................................................................... A.6

A.2.5 OIL LEAK HAZARD ................................................................................................................................... A.7

A.2.6 LOSS OF STABILITY ................................................................................................................................ A.8

A.2.7 SLIPPING AND FALLS............................................................................................................................ A.10

A.3 ELECTRIC SHOCK HAZARD.................................................................................................................A.11

A.3.1 CONTACT WITH LIVE COMPONENTS.................................................................................................. A.11

A.3.2 STATIC ELECTRICITY............................................................................................................................ A.12

A.4 HEAT HAZARDS ....................................................................................................................................A.12

A.4.1 BURNS .................................................................................................................................................... A.12

A.5 NOISE HAZARDS ...................................................................................................................................A.12

A.6 VIBRATION HAZARDS ..........................................................................................................................A.13

A.7 HAZARDS DUE TO TOXIC SUBSTANCES ...........................................................................................A.13

A.8 ERGONOMIC HAZARDS........................................................................................................................A.14

A.8.1MANUAL OPERATIONS ......................................................................................................................... A.14

A.8.2 VISIBILITY............................................................................................................................................... A.14

A.8.3 HUMAN ERROR...................................................................................................................................... A.14

A.9 UNEXPECTED START-UP AND SWITCH-OFF.....................................................................................A.15

A.10 FAULTS IN SAFETY DEVICES ..............................................................................................................A.15

A.11 COUPLING FAULTS...............................................................................................................................A.17

A.12 HAZARDS DUE TO INCORRECT LIFTING OPERATIONS...................................................................A.19

A.13 HOW TO TRANSPORT THE CRANE.....................................................................................................A.22

A.14 WARNINGS FOR USE WITH MANUAL EXTENSIONS .........................................................................A.23

A.15 WARNINGS FOR USE WITH BUCKET - GRAPPLE .............................................................................A.25

A.16 WARNINGS FOR USE WITH DRILL ......................................................................................................A.27

BUSER MANUAL.................................................................................................................. B.1

B.1 PREMISE ..................................................................................................................................................B.1

B.2 IDENTIFICATION......................................................................................................................................B.2

B.3 DESCRIPTION AND DOCUMENTATION.................................................................................................B.3

B.3.1 ENCLOSED DOCUMENTATION .............................................................................................................. B.3

B.3.2 MARK ........................................................................................................................................................ B.3

B.3.3 SERVICE CONDITIONS ........................................................................................................................... B.4

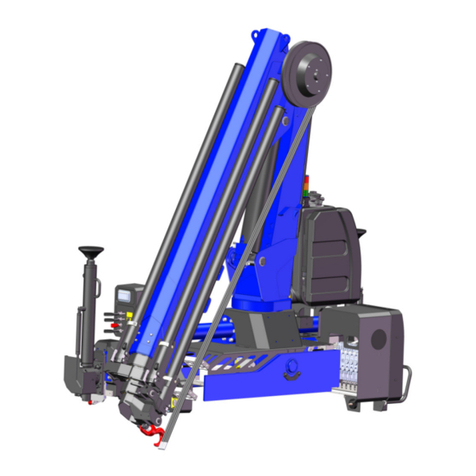

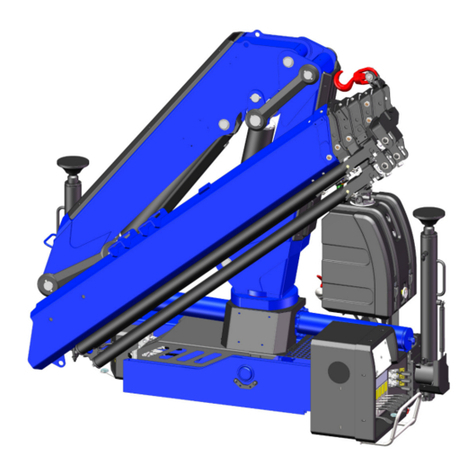

B.3.4 MAIN COMPONENTS ............................................................................................................................... B.5

B.4 CONTROLS ..............................................................................................................................................B.6

B.4.1 CONTROL STATIONS .............................................................................................................................. B.6

B.4.2 DESCRIPTION OF CONTROLS ............................................................................................................. B.11

B.4.3OUTRIGGERS CONTROLS (OPTIONAL) .............................................................................................. B.12

B.4.4 WORK LIGHTS CONTROL SWITCH (NO CE, NO TOP)........................................................................ B.12

B.4.5 EMERGENCY CONTROLS..................................................................................................................... B.13

B.5 SAFETY DEVICES..................................................................................................................................B.14

B.5.1 OVERCENTER VALVES ......................................................................................................................... B.14

B.5.2 EMERGENCY STOP BUTTON ............................................................................................................... B.14

B.5.3 MOMENT LIMITER.................................................................................................................................. B.15

B.5.4 LOCKING DEVICES FOR STABILIZER EXTENSIONS.......................................................................... B.16

B.5.5 LOCKING DEVICE FOR TURNING STABILIZER LEGS ........................................................................ B.17

B.5.6 SLEWING LIMITERS............................................................................................................................... B.17

B.5.7 LOCKING DEVICE FOR MANUAL EXTENSIONS.................................................................................. B.18

B.6 GAUGES AND INDICATORS .................................................................................................................B.19

B.6.1 GAUGES ON OIL TANK.......................................................................................................................... B.19

B.6.2 LOAD INDICATORS................................................................................................................................ B.20

B.6.3 LEVEL INDICATOR................................................................................................................................. B.21

B.6.4 HOURS COUNTER (NO CE, NO TOP)................................................................................................... B.22

B.6.5 VISUAL-AUDIBLE WARNING DEVICE IN CABIN .................................................................................. B.22

B.7 OPERATING THE CRANE .....................................................................................................................B.23

B.7.1 PRELIMINARY CHECKS BEFORE OPERATION................................................................................... B.23

B.7.2 START-UP OPERATION......................................................................................................................... B.23

B.7.3 HOW TO DEPLOY THE STABILIZERS WITH MANUALLY OPERATED EXTENSIONS ....................... B.24

B.7.4 HOW TO DEPLOY THE STABILIZERS WITH HYDRAULICALLY OPERATED EXTENSIONS ............. B.27

B.7.5 HOW TO ROTATE DOWNWARDS THE MANUAL TURNING STABILIZER LEGS................................ B.30