WALL PANEL/LINER INSTALLATION (continued) TIME REQUIRED

3-4 HR

10

1T

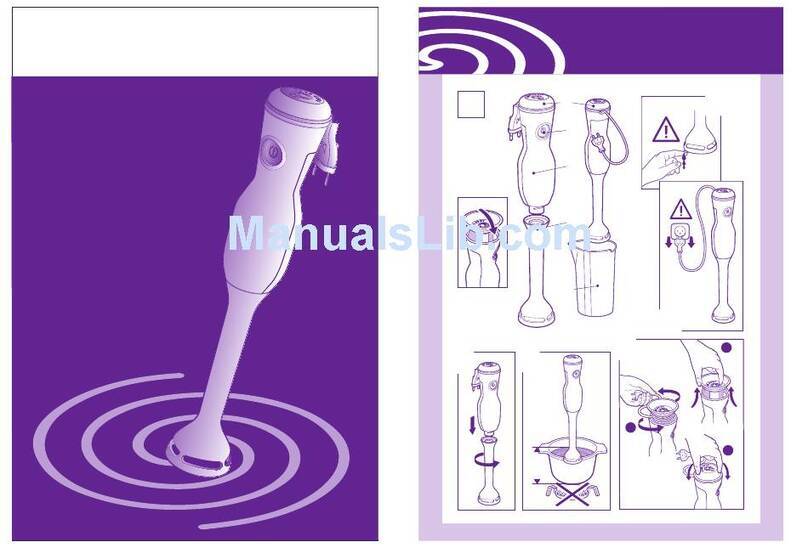

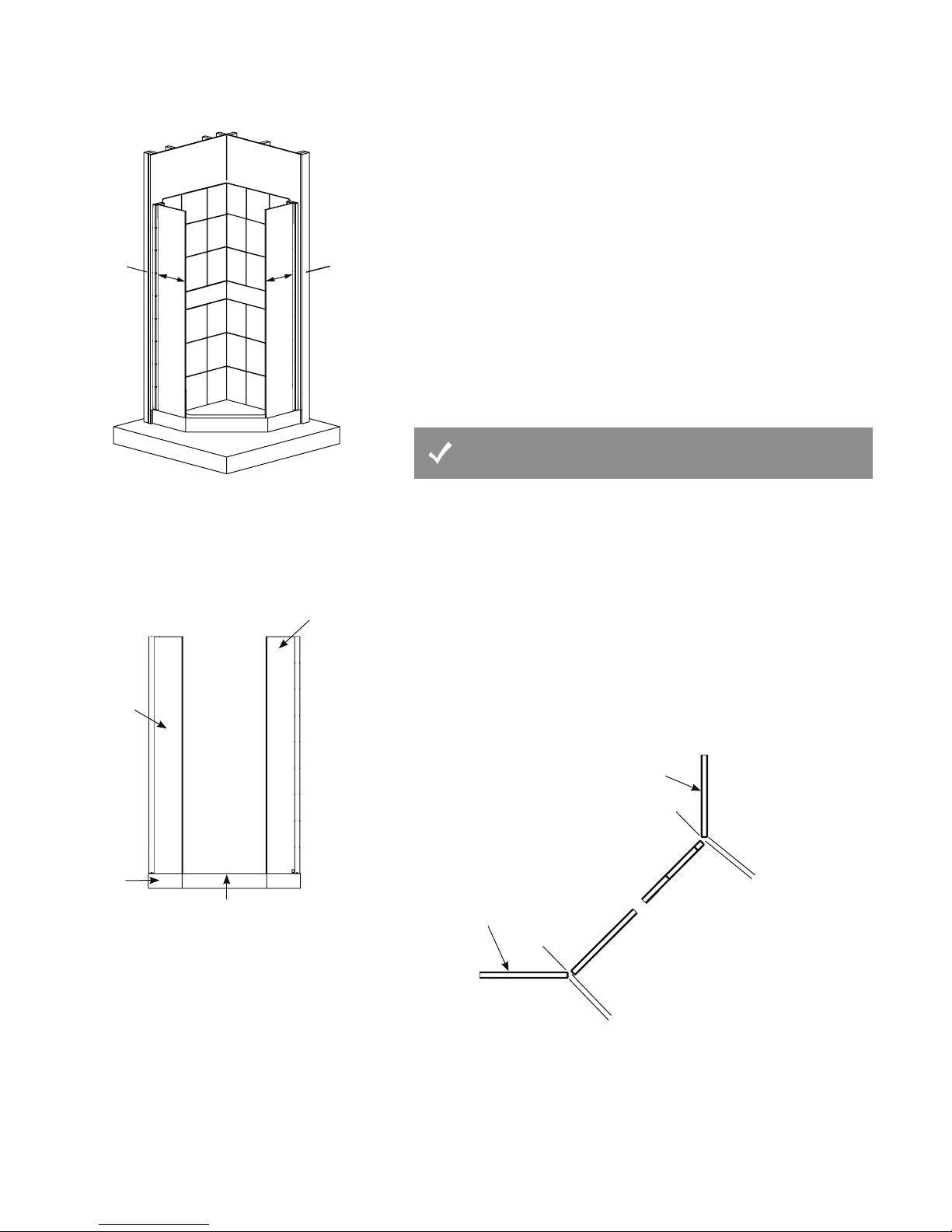

C - Installing Panels

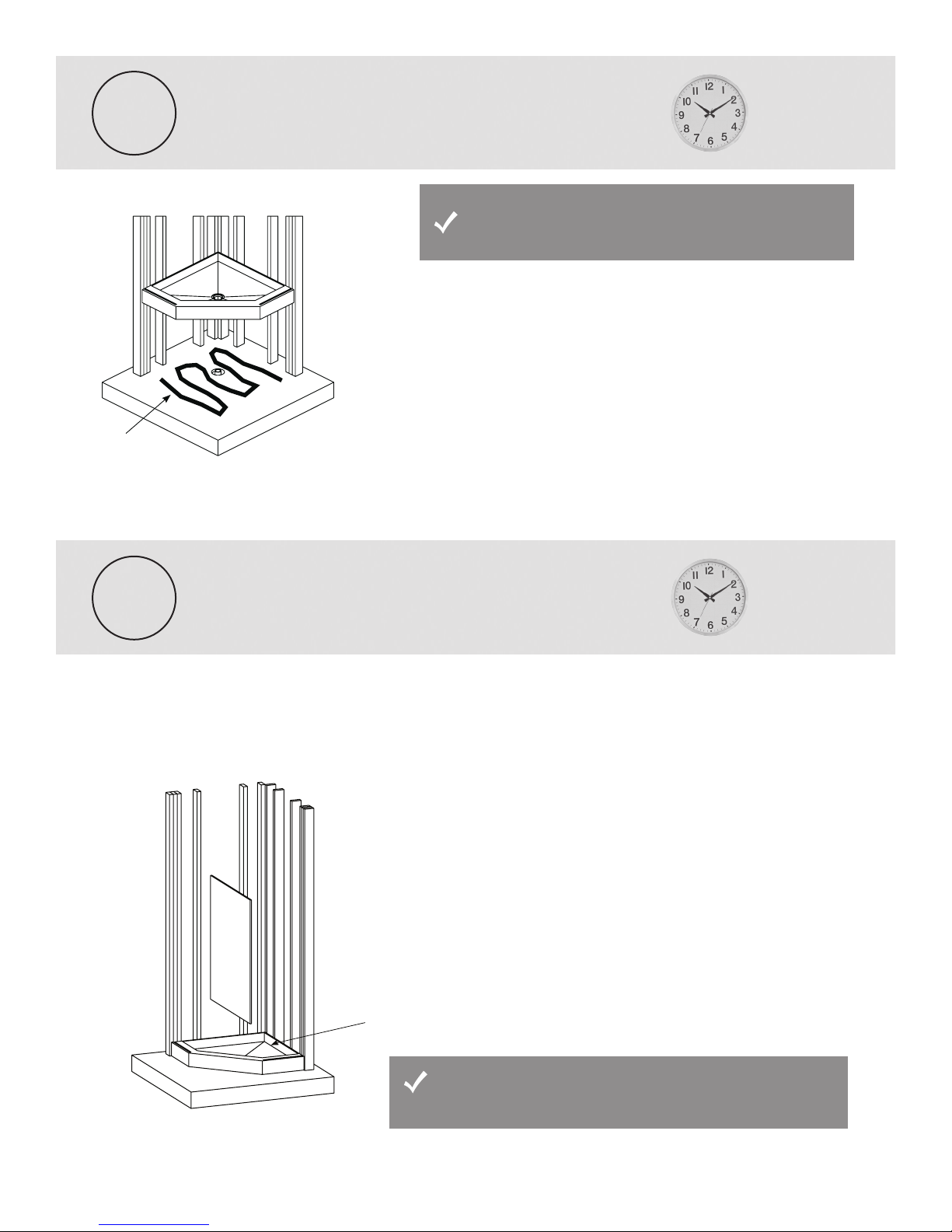

8. Sand the backside surface of the wall panels with 60 grit sandpaper. This will increase the bond

to the silicone. Remove all dust and dirt with a clean dry cloth.

9. Start with panel 2B, apply a generous amount of silicone to the cement board and to the back

side of the wall panel. Refer to “Silicone Recommendations” on previous page for applying

silicone. Also refer to the manufacturer’s recommendations for application and drying time.

10. Press the wall firmly into position. Be sure to use spacers between the bottom panel and the

shower pan to ensure panel is level. (diagram 12)

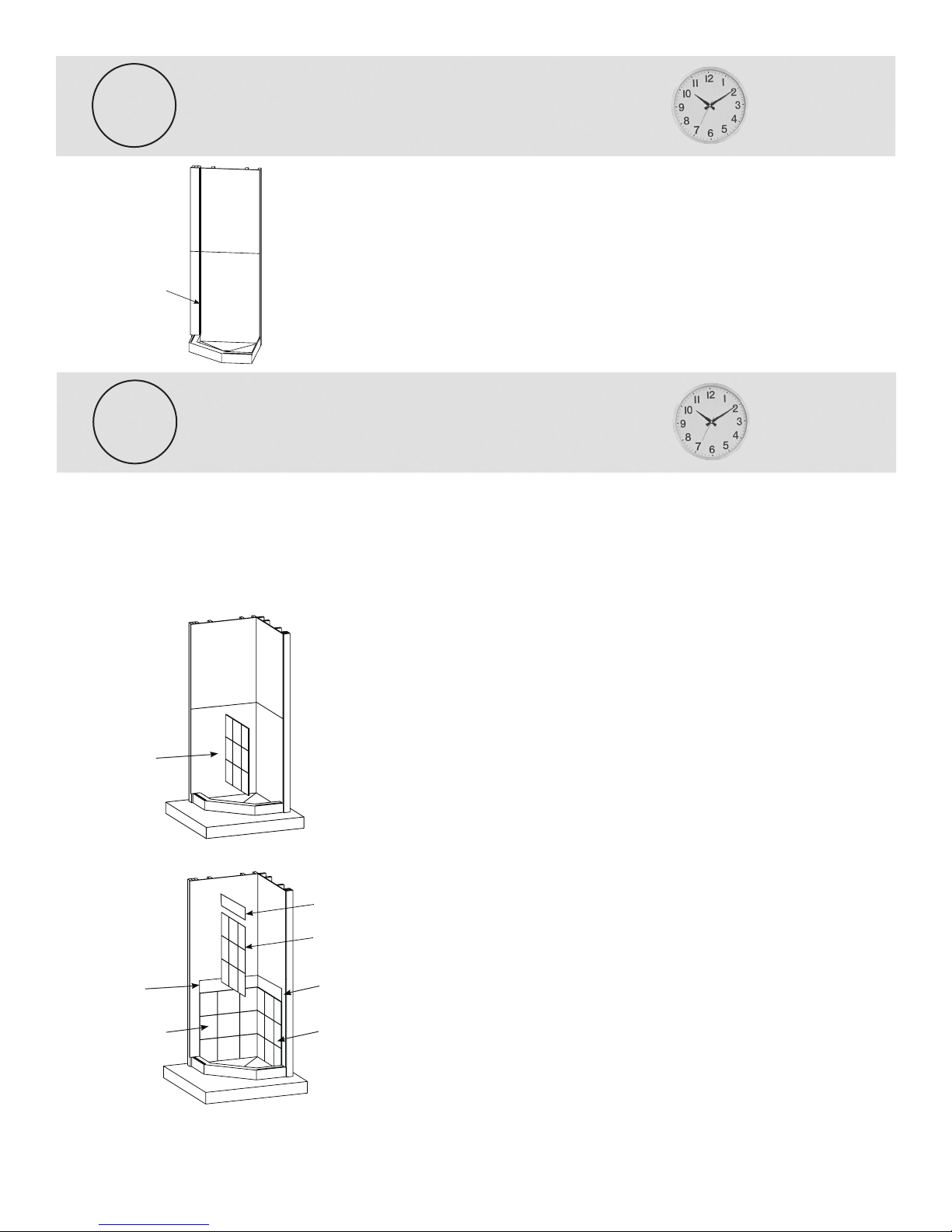

11. Install the remaining panels in the following order: 1B, 1L, 2B, 2L, 1T, 1LT, 2T & 2LT.

Match the space between the panels with the rest of the grout lines on the panel.

Use spacers if necessary to make the walls square and straight.

diagram 12

THRESHOLD TRIM TIME REQUIRED

1/2 - 1 HR

11

8

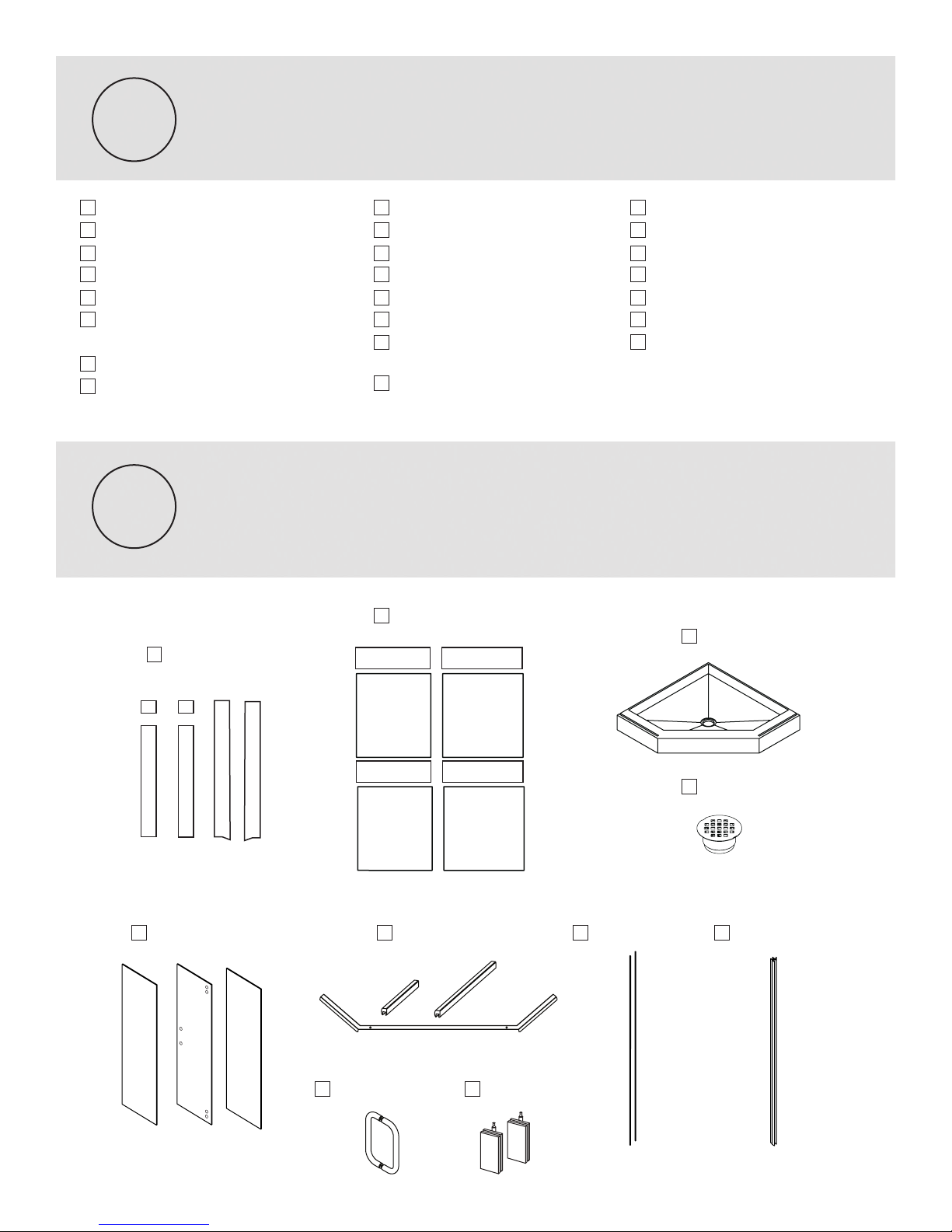

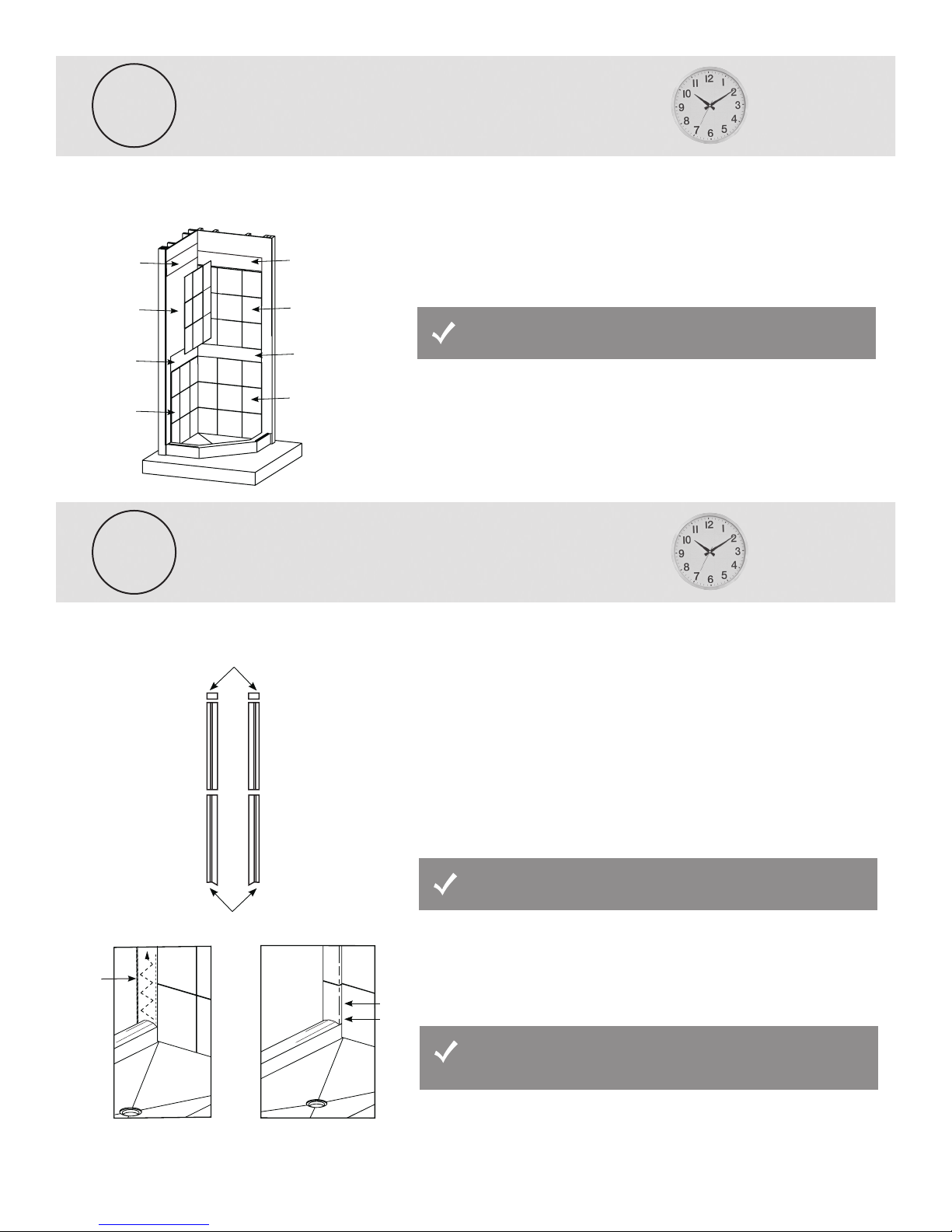

The threshold trim pieces complete the look of your new shower system. If you purchased a Basic

Package which does not come with glass, your threshold pieces will be solid, without a channel. If

you purchased a Supreme Package which comes with glass, the threshold pieces will have a channel

for the glass panels. No matter what package you ordered there are 2 special cap trim pieces and 2

special notched bottom left and right pieces.

1. Locate all the trim pieces and align them on the floor. (diagram 13)

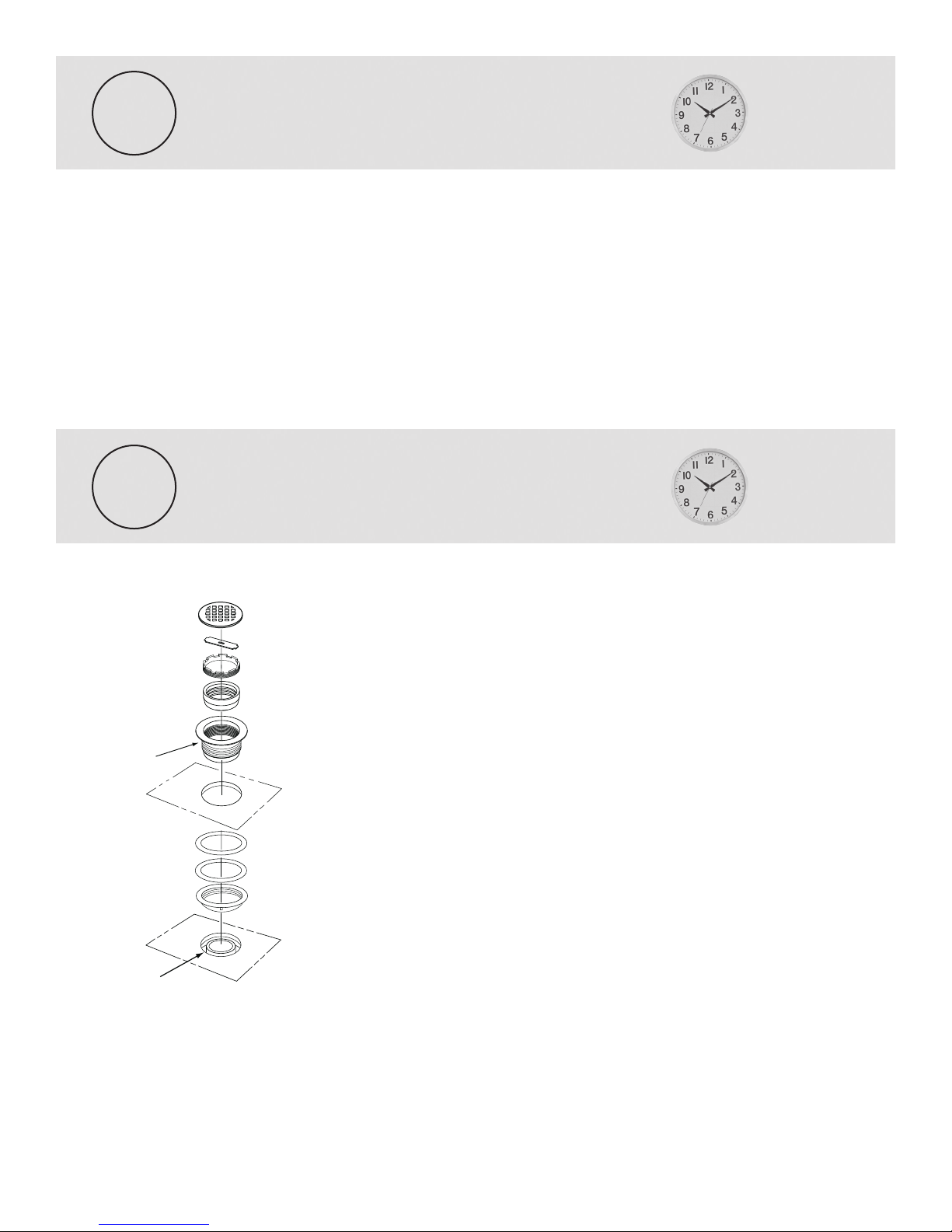

2. Apply silicone, using a zig-zag pattern, to the cement board along the panel’s edge, approximately

4 inches out: to the far outside of the shower pan. (diagram 14)

Do not install the small cap trim pieces if your package includes glass. These trim pieces are to be

installed after the glass and door have been installed. If you did not purchase a package

with glass, you can install the cap trim pieces now.

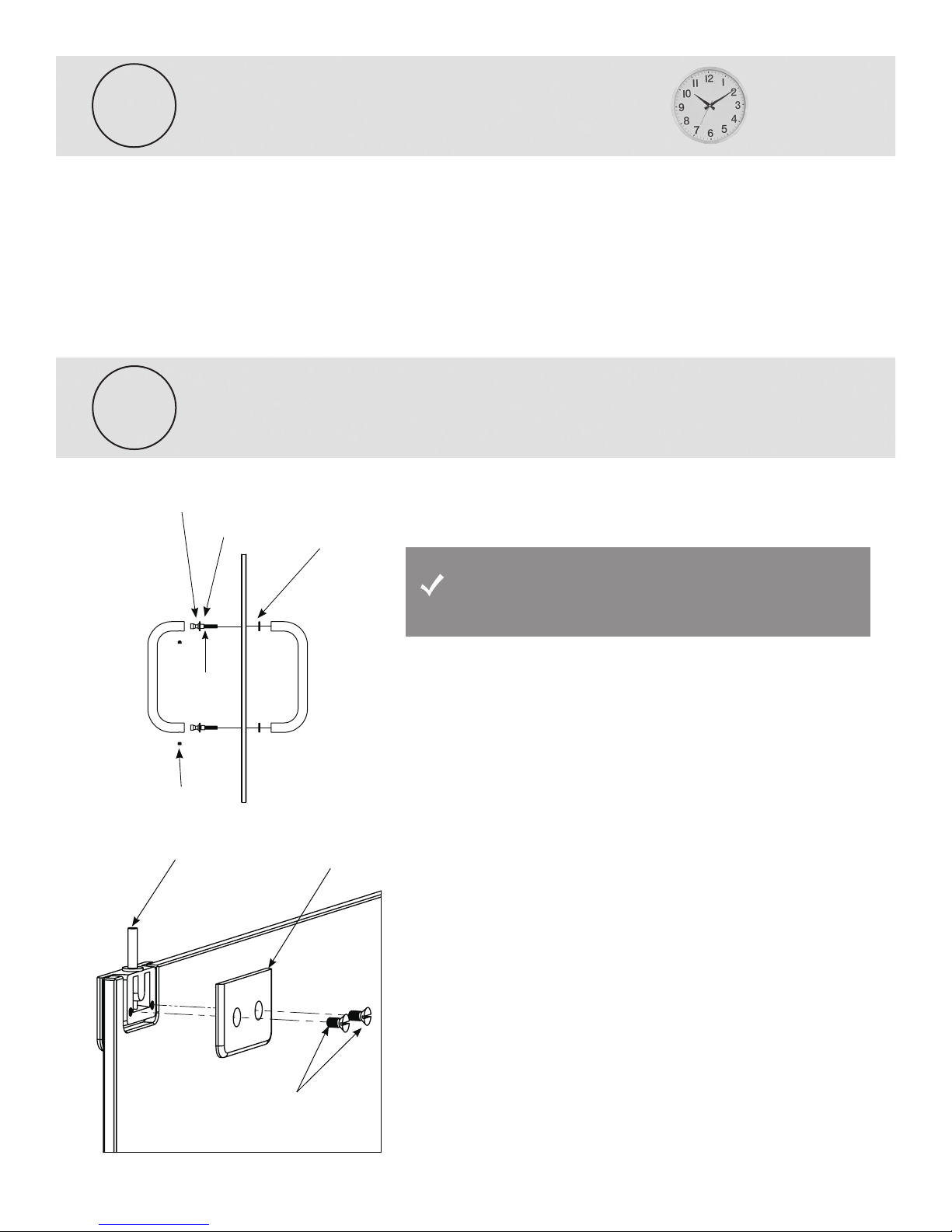

3. Starting with the special bottom threshold piece, place the threshold into position making sure to

align the threshold with the vertical plumb line previously drawn on the cement

board. Apply pressure to the trim piece to bond it to the cement board. The trim piece should be

flush with the inside of the shower pan threshold. (diagram 15) Make sure to align the glass

channels in the thresholds with the glass channels in the shower pan. (if glass unit)

4. Place the remaining trim pieces into position. Make sure to use a level and the plumb line

previously drawn on the cement board to align the trim pieces vertically.

Wall thresholds should be flush on the inside and

outside of the pan

See manufacturer’s recommendations for drying time

cap trim pieces

TLC TRC

TLT TRT

TLB TRB

diagram 13

special notched bottom pieces

diagram 14 diagram 15

1B

1L

2T

2L

2B

Braces may be required to keep walls flush

cement

board

2LT

1LT