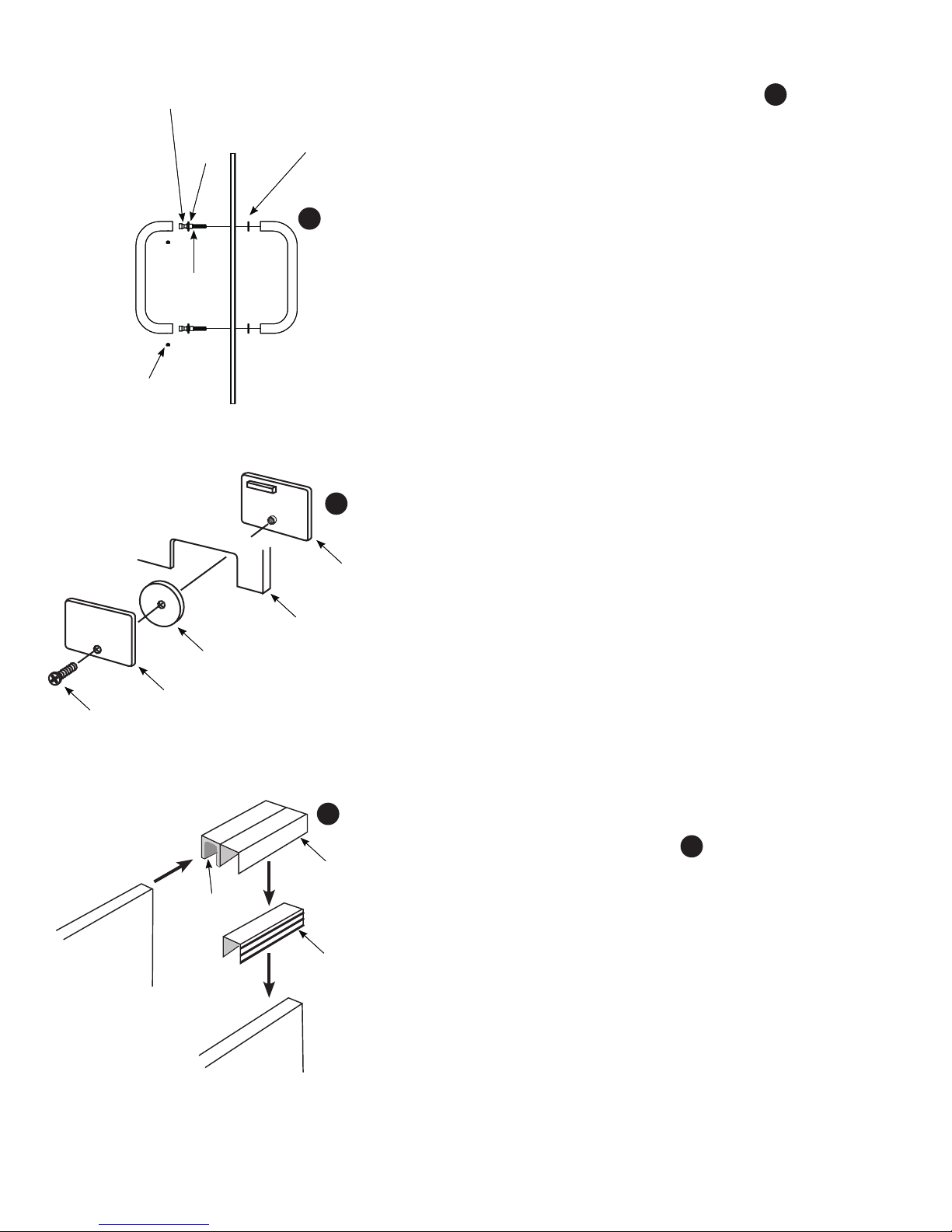

apply 100%

RTV silicone

6TIME REQUIRED

½ HR

6

7CEMENT BOARD INSTALLATION TIME REQUIRED

1-2 HRS

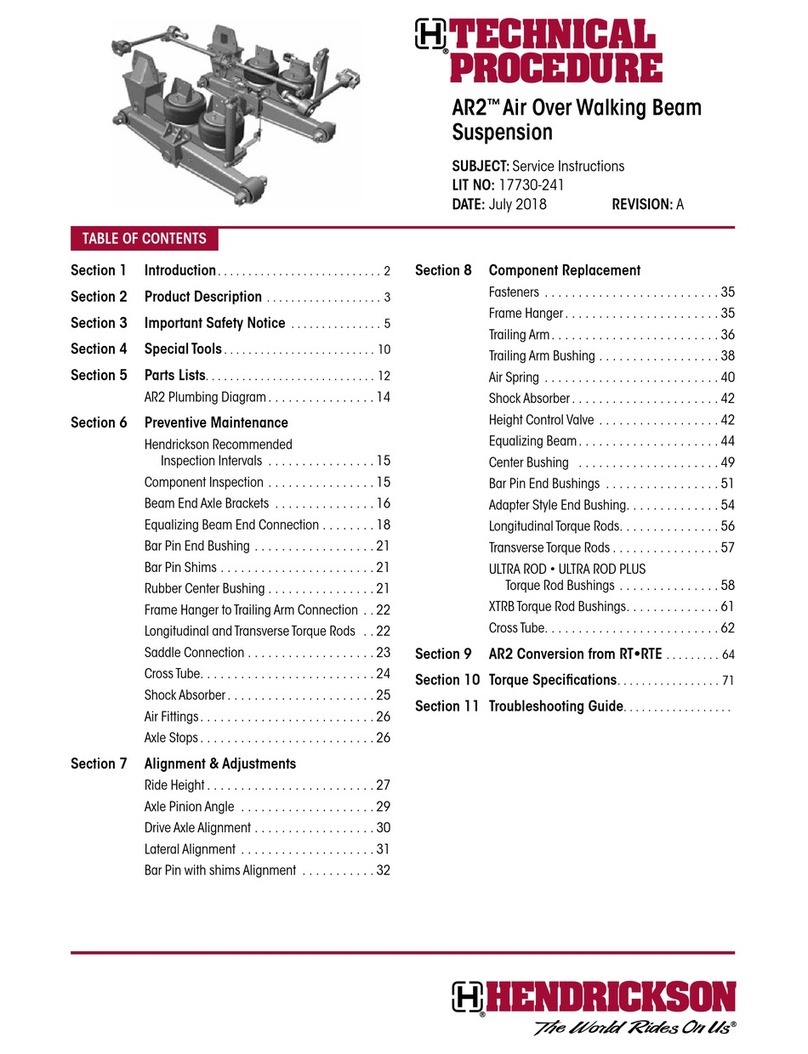

We recommend the use of 1/2” thick cement board as your shower backer. This is a common backer for stone and tile. Using this backer will help comply with

almost all city codes. A cement-based product like Wonderboard or Hardibacker may also be used if it meets your local codes. Some codes require a vapor

barrier to be installed as well. We recommend a water/vapor barrier of 6 mil. plastic be installed before installing the cement board. To do this, staple plastic

so that it hangs 1” above the floor. Roofing nails may be used to attach the cement board instead of screws, this prevents the plastic from wrapping around the

screws.

SETTING PAN

1. IMPORTANT: Use your cement board as an indicator of squareness. The cement board comes in

square sheets. If you see gaps or areas where the cement board is not fitting flush, fix

the problem by removing the cement board and shimming the board until it’s square and

flush. If the seams of the cement board are not flush and square, your wall panels will not

be square and flush.

2. Cut a notch in cement board to fit around threshold. Sanding or shimmimg the 2 x 4’s at the

top rim of the pan may be required to flush the cement board. (diagram 8)

2. Place a bead of 100% RTV silicone on the front INSIDE face of the shower pan flange. The bead

should be in a zig-zag pattern.

3. Place the cement board against the studs and rest it inside the shower pan against the back

flange. Attach the cement board to the studs with screws or nails. Do not screw or nail into

the shower pan flange.

4. Continue installing the remaining cement boards.

For best cutting results for wall panels and cement board, use a Makita grinder with a 4” tile blade.

notch

diagram 8

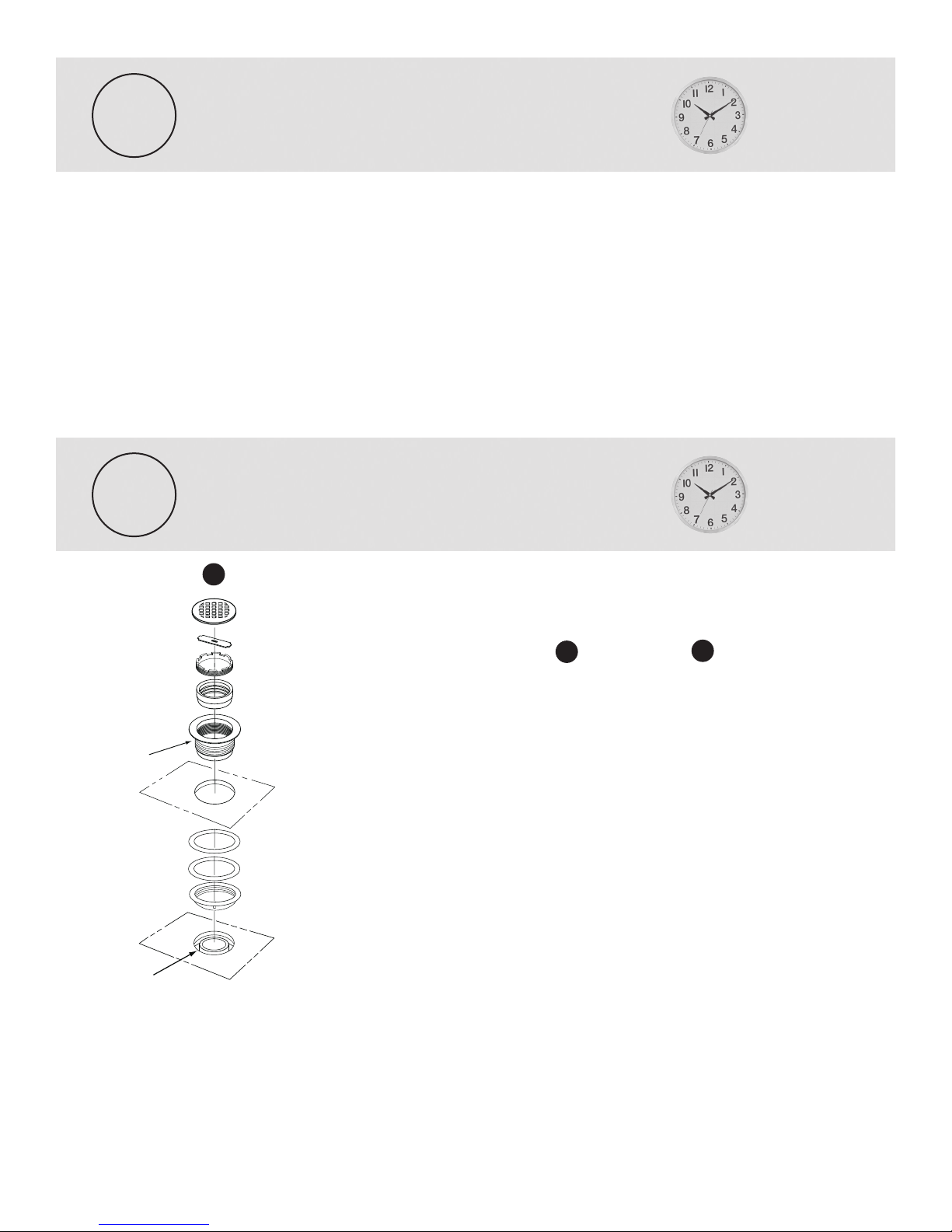

1. Now that the drain is installed into the pan dry fit the pan and drain for alignment, check to

make sure the 2” drain pipe is in the center of the pan drain hole. (diagram 2) Use the drain

collar #5 by itself; remove the rubber seal, nut and gaskets from the drain assembly.

(diagram 3, previous page) Push the drain collar #5 into the drain hole between the pan

and the 2” pipe. With the drain collar pushed flush to the pan surface, the 2” drain pipe should

not extend past the inside threads of the drain collar #5.

2. Make sure the pan and drain fit level to the floor (the pan can be secured to the floor by nailing

the pan flange to the studs, this can only be done after step 3 is completed)

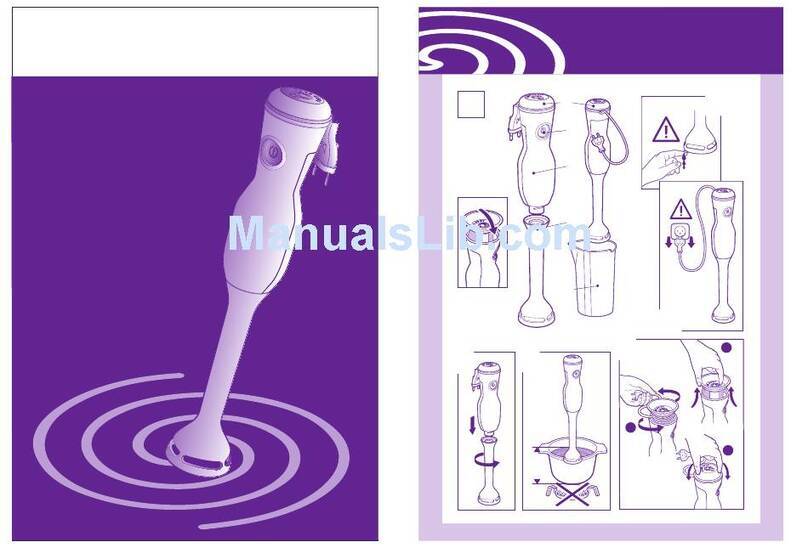

3. Remove pan and apply 100% RTV Silicone to the floor (diagram 7)

4. Carefully lift the shower pan and set into place. Make sure the ABS pipe is still centered.

5. Push and secure the rubber seal #4 onto the 2” ABS pipe.

6. Thread on the brass pressure ring #3 around the drain pipe with the provided tool #2.

Remove the tool after the brass pressure ring is installed.

7. Test and snap the decorative diamond trim plate #1 into position. (Remove the decorative trim

plate and store in secure area until installation is complete, drain will be grouted when shower is

grouted).

8. After installing pan, cover with cardboard or drop cloth to protect pan from scuffs.

diagram 7