Page 2 Dwg. No. X730377 P02

Read this manual carefully before attempting to install, operate, or

perform maintenance on this unit. Installation and maintenance

should be performed by qualified service technicians only.

NOTE: “Warnings” and “Cautions” appear at appropriate

places in this manual. Your personal safety and the proper

operation of this air conditioning product require that you follow

them carefully. The manufacturer assumes no liability for

installations or servicing performed by unqualified personnel.

INSPECTION

1. Check for damage after the unit is unloaded. Report promptly,

to the carrier, any damage found to the unit. Do not drop the unit.

IMPORTANT: The use of “spreader bars”is required when

hoisting the unit (to prevent damage to sides and top).

2. Check the unit’s nameplate to determine if the unit is correct for

the intended application. The power supply must be adequate

for both the unit and all accessories.

3. Check to be sure the refrigerant charge has been retained during

shipment.

GENERAL INFORMATION

IMPORTANT: RECONNECT ALL GROUNDING DEVICES.

ALL PARTS OF THIS PRODUCT CAPABLE OF CONDUCTING

ELECTRICAL CURRENT ARE GROUNDED. IF GROUNDING

WIRES, SCREWS, STRAPS, CLIPS, NUTS OR WASHERS

USED TO COMPLETE A PATH TO GROUND ARE REMOVED

FOR SERVICE, THEY MUST BE RETURNED TO THEIR ORIGI-

NAL POSITION AND PROPERLY FASTENED.

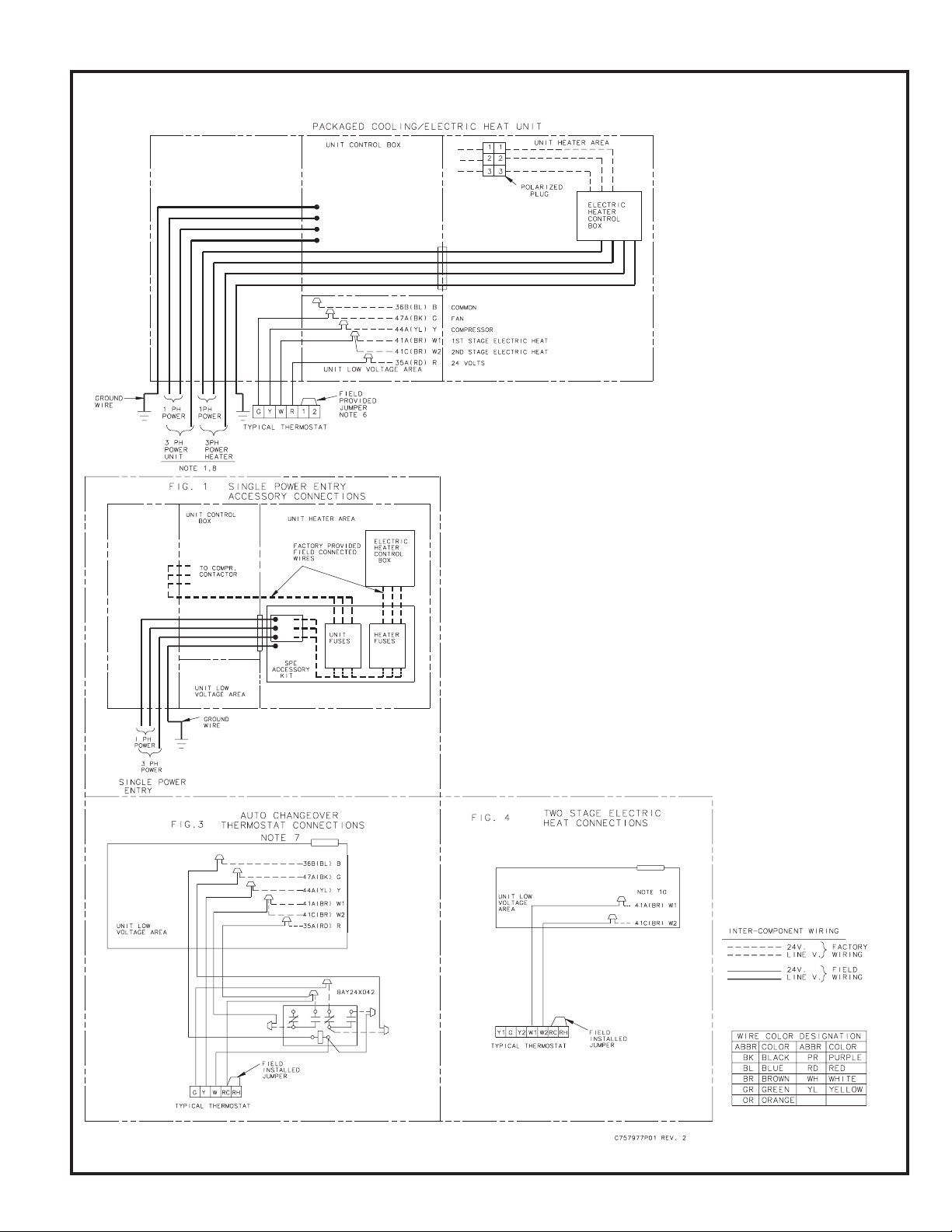

IMPORTANT: ALL POWER LEGS MAY NOT BE BROKEN BY

CONTACTORS. SEE WIRING DIAGRAM ON UNIT CONTROL

BOX COVER.

BEFORE STARTING THE COMPRESSOR, THE CRANKCASE

HEATER SHOULD BE ENERGIZED FOR EIGHT HOURS.

SAFETY NOTICE. THIS INFORMATION IS INTENDED FOR

USE BY INDIVIDUALS POSSESSING ADEQUATE BACK-

GROUNDS OF ELECTRICAL AND MECHANICAL EXPERI-

ENCE. ANY ATTEMPT TO REPAIR A CENTRAL AIR CONDI-

TIONING PRODUCT MAY RESULT IN PERSONAL INJURY

AND/OR PROPERTY DAMAGE. THE MANUFACTURER OR

SELLER CANNOT BE RESPONSIBLE FOR THE INTERPRE-

TATION OF THIS INFORMATION, NOR CAN IT ASSUME

LIABILITY IN CONNECTION WITH ITS USE.

IMPORTANT: Read this entire manual before beginning instal-

lation procedures.

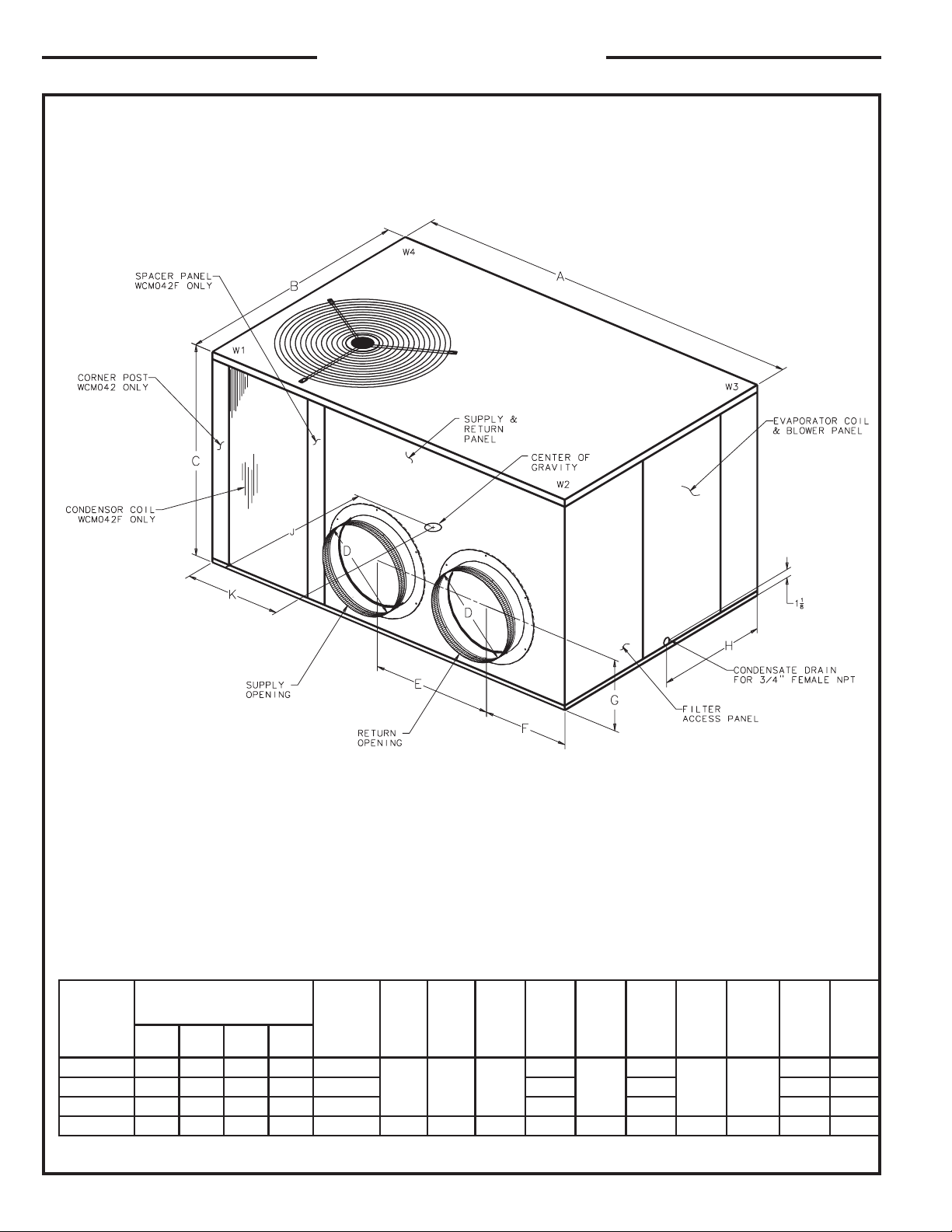

These units are designed for outdoor installation. For proper instal-

lation, the following recommendations must be considered.

Select a location that will permit unobstructed airflow into the

condenser coil and away from the fan discharge and permit unob-

structed service access into the compressor compartment. Sug-

gested airflow clearances and service clearances are given in

Figure 2.

NOTE: Unit shipped for horizontal installation.

The discharge air from the condenser fans must be unrestricted for

a minimum of 3 feet above the unit.

NOTE: If any internal accessories are to be added to the unit it

should be done at the shop if at all practical.

1. Unit should be positioned so Roof-Run-Off water does not pour

directly on unit.

2. Exhaust vents or other sources of contaminated air should not

be near unit air inlet if outside air is to be introduced as a make-

up air or the economizer ventilation feature is to be used.

3. Check the handling facilities to insure the safety of personnel and

the unit(s).

4. CAUTION MUST BE TAKEN AT ALL TIMES TO AVOID PER-

SONAL INJURIES AND/OR DAMAGE TO EQUIPMENT.

5. The unit must be mounted level for proper drainage of defrost

water through the holes in the base pan.

6. Flexible duct connectors must be of a flame retardant material. All

duct work outside of the structure must be insulated and weath-

erproofed in accordance with local codes.

7. Holes through exterior walls must be sealed in accordance with

local codes.

8. Access and service clearances for the unit must be given careful

consideration when locating the duct entrance openings. Fig-

ures 1 and 2 provide unit dimensions.

9. All fabricated outdoor ducts should be as short as possible.

10. Be sure the hole in the structure for the ducts is large enough to

accommodate the fabricated ducts and the insulation surrounding

them.

CLEARANCES

1. The recommended clearances for single-unit installations are

illustrated in Figures 1 and 2. These minimum requirements are not

only an important consideration when determining unit placement,

but they are also essential to ensure adequate serviceability,

maximum capacity, and peak operating efficiency.

2. Any reduction of the unit clearances indicated in this illustration

may result in condenser coil starvation, or the recirculation of warm

condenser air.

LOCATIONS AND RECOMMENDATIONS