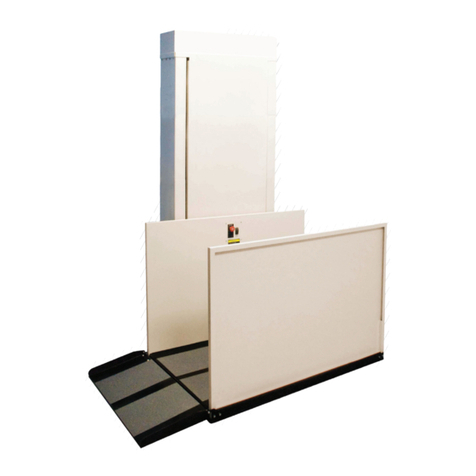

STRATOS VERTICAL PLATFORM LIFTS: Install Manual

04DEC2020 | 630-00147 REV A

3

TABLE OF CONTENTS

STRATOS

TABLE OF CONTENTS

SAFETY ............................................................................................ 4

Safety Definition ................................................. 4

Environmental Cautions ...................................... 4

INTRODUCTION ............................................................................ 5

Device Name: Ameriglide Stratos VPL .................. 5

Read and Understand .......................................... 5

Technical Specifications ...................................... 5

Code Statement .................................................. 5

Applicable Standards Based

on Installation Type ............................................. 5

Requirements under ASME A18.1 ........................ 6

ASME A18.1 Section 2: Vertical Platform Lifts ..... 6

ASME A18.1 Section 5:

Private Residence Vertical Platform Lifts ............. 6

Statement of Use ................................................ 6

Key Vertical Platform Lift Elements ..................... 7

Key Internal Vertical Platform Lift Elements ........ 8

PREPARATION ............................................................................... 9

Required Tools .................................................... 9

Recommended Tools ........................................... 9

Box Content ...................................................... 10

Required Components Not Supplied .................. 10

Unloading .......................................................... 10

Unpacking ......................................................... 10

Concrete ........................................................... 11

Material Handling .............................................. 11

Hoist Way (Shaft) .............................................. 11

Site Preparation ................................................ 11

INSTALLATION ............................................................................ 12

No Hoistway / No Floor Penetration .................. 12

Platform Connection ......................................... 12

Installing the Platform Control Guard Panel ...... 13

Installing a Platform Gate (If Equipped) ............. 14

Installing the Platform Front Guard Panel ......... 14

Installing the Auto-Folding Ramp ...................... 14

Installing the Top Landing Gate ......................... 15

Fascia Panel Installation .................................... 16

Setting the Upper Limit Switch .......................... 16

Doors / Gates by Others .................................... 17

Call Stations ...................................................... 17

Final Positioning and Anchoring ........................ 18

Installing Fixed Ramps ....................................... 18

Installation Tower Check ................................... 19

Final Installation ................................................ 19

Operational Check ............................................. 20

Permanent Power Installation ........................... 20

Operator Familiarization ................................... 21

INSTALLATION QUICK START ............................................... 22

TROUBLESHOOTING ................................................................ 23

Status Codes ..................................................... 23

Control Electronics ............................................ 26

Control Electronics Tray .................................... 26

Control Board .................................................... 27

Gearmotor ........................................................ 32

Contactor Tray .................................................. 33

Up and Down Contactors .................................. 33

E-Brake Resistor ................................................ 33

Load Resistors ................................................... 33

Cooling Fan ....................................................... 33

Battery Backup .................................................. 33

Emergency Evacuation Procedure ..................... 35

Emergency Lowering Procedure ........................ 35

MAINTENANCE & INSPECTION ............................................ 37

Residential Applications .................................... 37

Commercial Applications ................................... 37

Maintenance Schedule ...................................... 38