TABLE OF CONTENTS T-I

Table of Contents

General Information ....................................................................... P-1

Initial Inspection ..................................................................................................................................P-1

Features ................................................................................................................................................P-1

High Temperature Alarm.................................................................................................................P-1

Specifications.......................................................................................................................................P-1

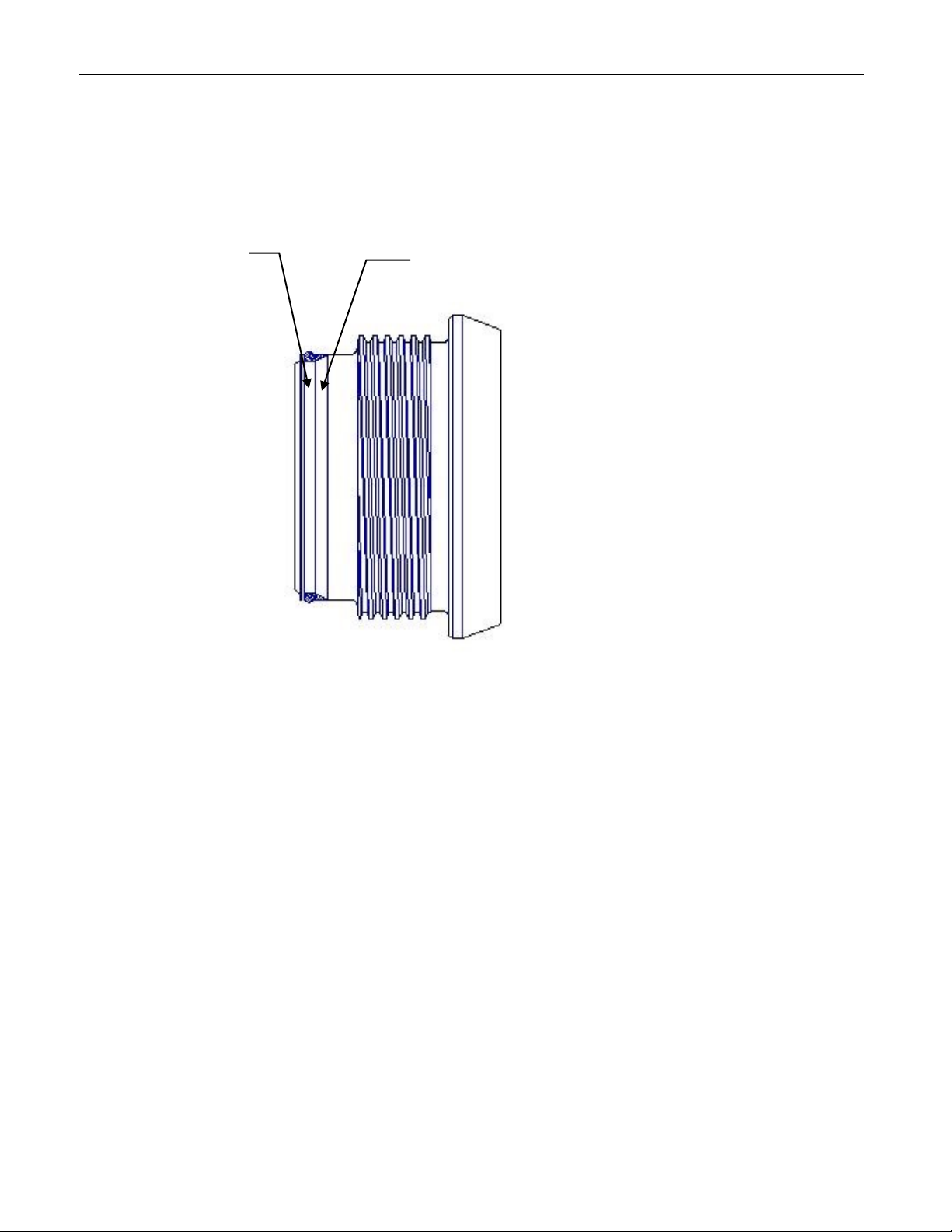

About the High Pressure Seal ..............................................................................................................P-2

Where to Find Help..............................................................................................................................P-3

Section 1 - Installation.....................................................................1-1

Site Requirements ................................................................................................................................ 1-1

Connecting Air and Water ................................................................................................................... 1-1

Connecting Power to the Curing Chamber .......................................................................................... 1-2

Section 2 - Curing Chamber Controls..............................................2-1

Safety Procedures................................................................................................................................. 2-1

Power Switch ................................................................................................................................... 2-1

Model 7050 Temperature Controller ............................................................................................... 2-1

Drain Cylinder/Fill Cylinder switch ................................................................................................ 2-2

Heater Switch................................................................................................................................... 2-2

Pressurize Cylinder Switch.............................................................................................................. 2-2

Cool Cylinder Switch....................................................................................................................... 2-2

Cylinder Drain Valve....................................................................................................................... 2-2

Pump Pressure Adjust Regulator ..................................................................................................... 2-3

Temperature Limit Alarm ................................................................................................................ 2-3

Temperature Limit Alarm Reset ...................................................................................................... 2-3

Section 3 - Operation.......................................................................3-1

Preparation of Cement Sample ............................................................................................................ 3-1

Installing Cylinder Plug ....................................................................................................................... 3-1

Filling Cylinder with Water................................................................................................................. 3-1

Temperature Control............................................................................................................................ 3-2

Pressure Control................................................................................................................................... 3-2

Running the Test.................................................................................................................................. 3-3

If Temperature Limit Alarm Occurs ................................................................................................ 3-3

Cooling the Cylinder............................................................................................................................ 3-3

Draining the Cylinder .......................................................................................................................... 3-4