7

Amphenol Network Solutions

All rights reserved. 12.18.19 139688-3

509.926.6000 – amphenol-ns.com

100A Dual-Feed

Breaker Panel

Remember: Output wires must be rated at or above the amperage rating of the output circuit breaker. For

example, use no smaller than #12 AWG output wiring for 20A output fuses. Do not exceed 16A

continuous load for a 20A breaker.

ALERT! Local electrical and operating company guidelines recommend that the individual load

not exceed 80% of circuit breaker capacity (for example, 10A breaker x .80 = 8A max. load).

Total load for all breaker outputs on each side must not exceed 100A.

18. Clean output terminals and lugs with a nonabrasive, nonmetallic pad.

19. If covers are installed, remove the covers over the output and alarm connectors.

20. Amphenol Network Solutions recommends that you lightly coat antioxidant on lugs and output

BATTERY and RETURN terminals before connecting lugs/wires to outputs. (NEC specifies only one

lug and load for each output terminal.) Tighten the screws to 9 in.-lb (1.01 N•m).

21. Connect the other end of output wires to load.

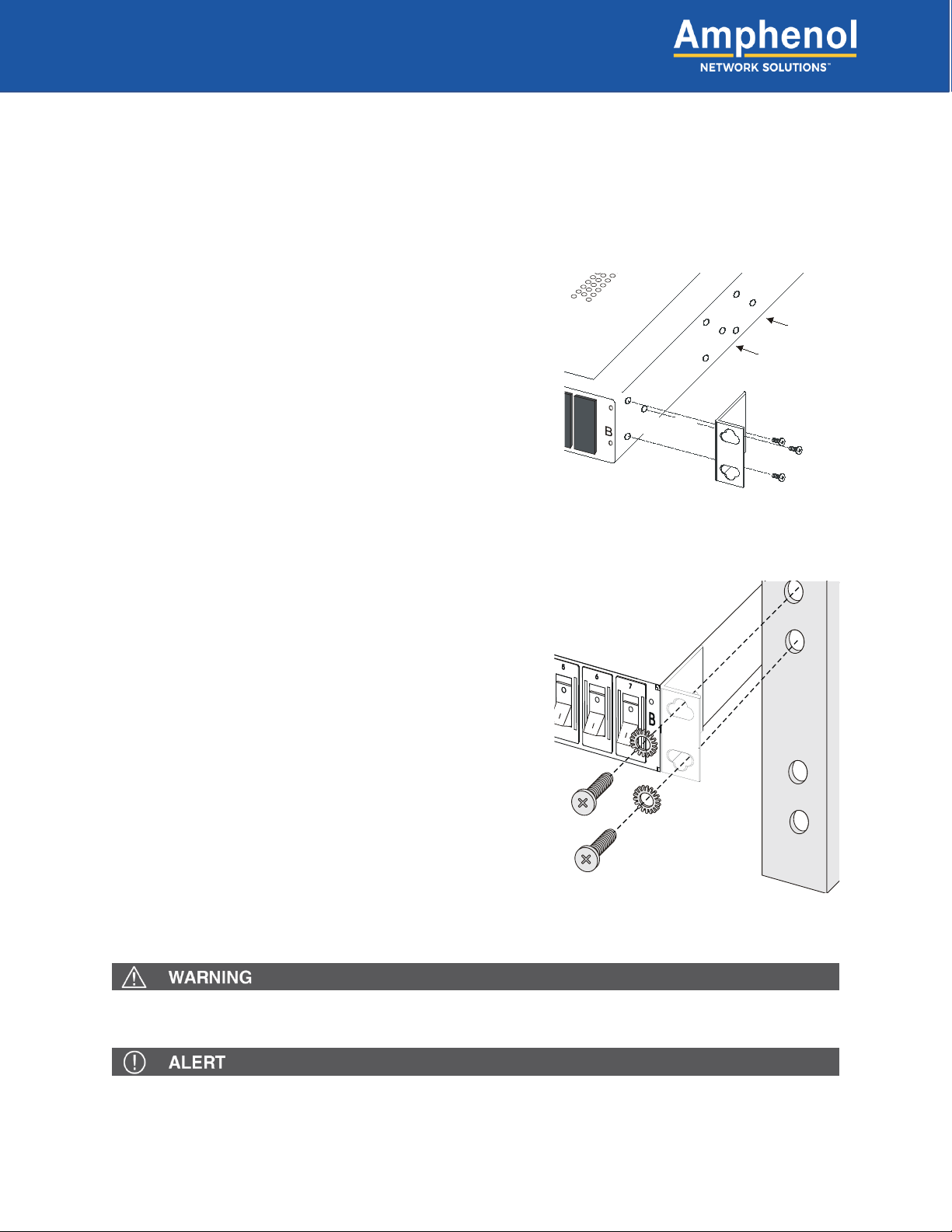

22. Use the designation labels (supplied) to record

outputs, as specified by operating company

standard installation procedures.

23. Make sure inputs at loads are disabled by

removing all power cards or all input fuses

at load equipment.

Always follow recommended operating

company guidelines when disabling

load equipment.

24. One by one, turn on circuit breakers on this

panel and check voltage and polarity at input of loads.

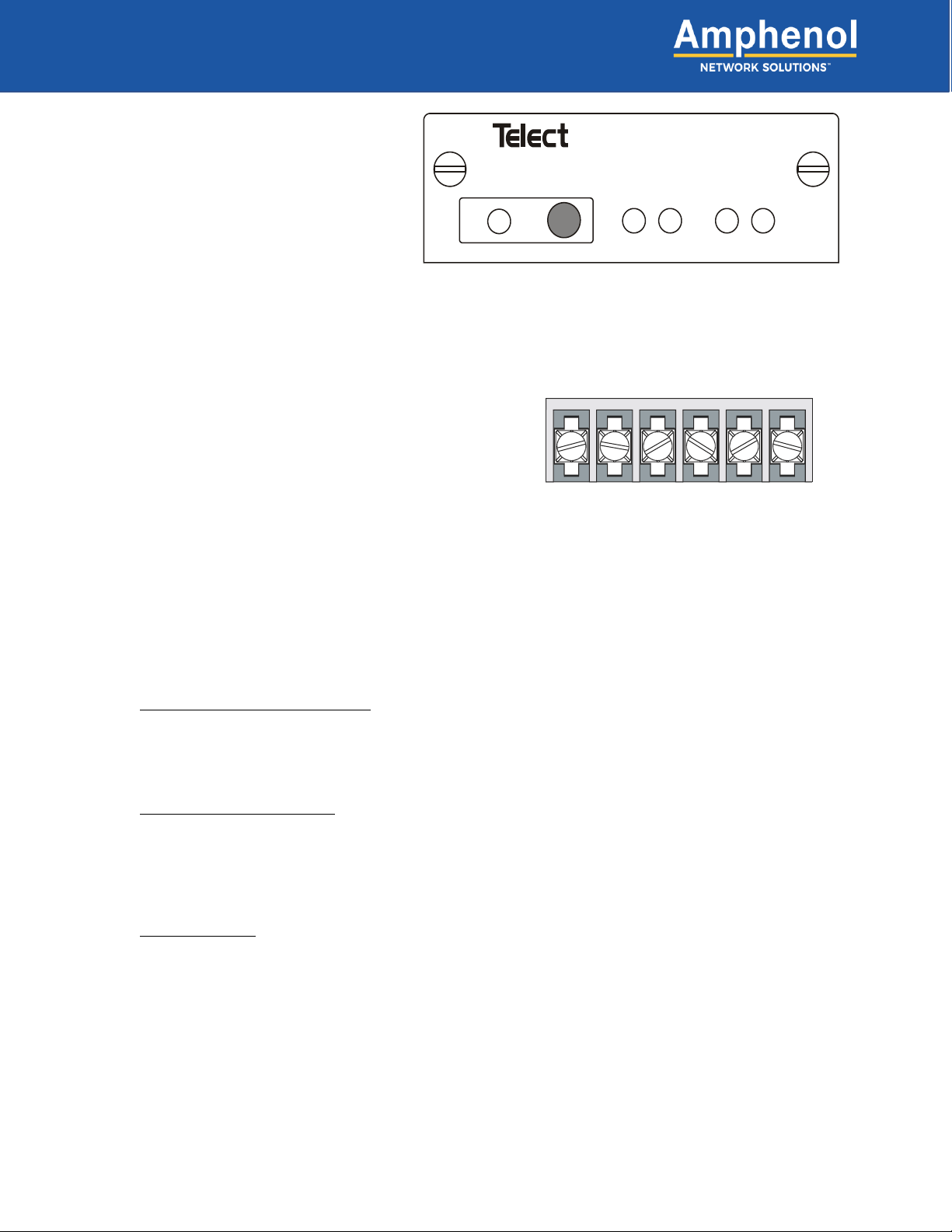

25. With all circuit breakers on, the BREAKER ALARM LED must go off. Test fuse alarm relay contacts

at FUSE ALARM terminals on rear of panel:

•Expect continuity (0Ω)between Terminals Cand NC.

•Expect an open circuit (∞Ω) between Terminals C and NO.

26. Switch off one of the circuit breakers to simulate a tripped breaker.

Again, the BREAKER ALARM LED should light.

27. Press ALARM RESET on front of panel.

The BREAKER ALARM LED should go off again. (Pressing ALARM RESET will reset the BREAKER

ALARM LED on front and clear FUSE ALARM on rear of panel.) Recheck the FUSE ALARM

terminals and expect the same status as in step 25 with all breakers on.

28. If desired, connect remote external audio/visual alarm indicator wires (solid or tinned wires, #30 to

#16 AWG) to the POWER FAIL and FUSE ALARM terminals.

29. One by one, re-enable load equipment and verify proper operation.

Figure 8 – Designation Label