ABBREVIATED COMPONENT MAINTENANCE MANUAL

P/N 504414-SERIES

PAGE 3 OF 42

June 9, 2014

Rev. 2

25-20-217

Use or disclosure of information on this page is subject to the restrictions on the title page of this document

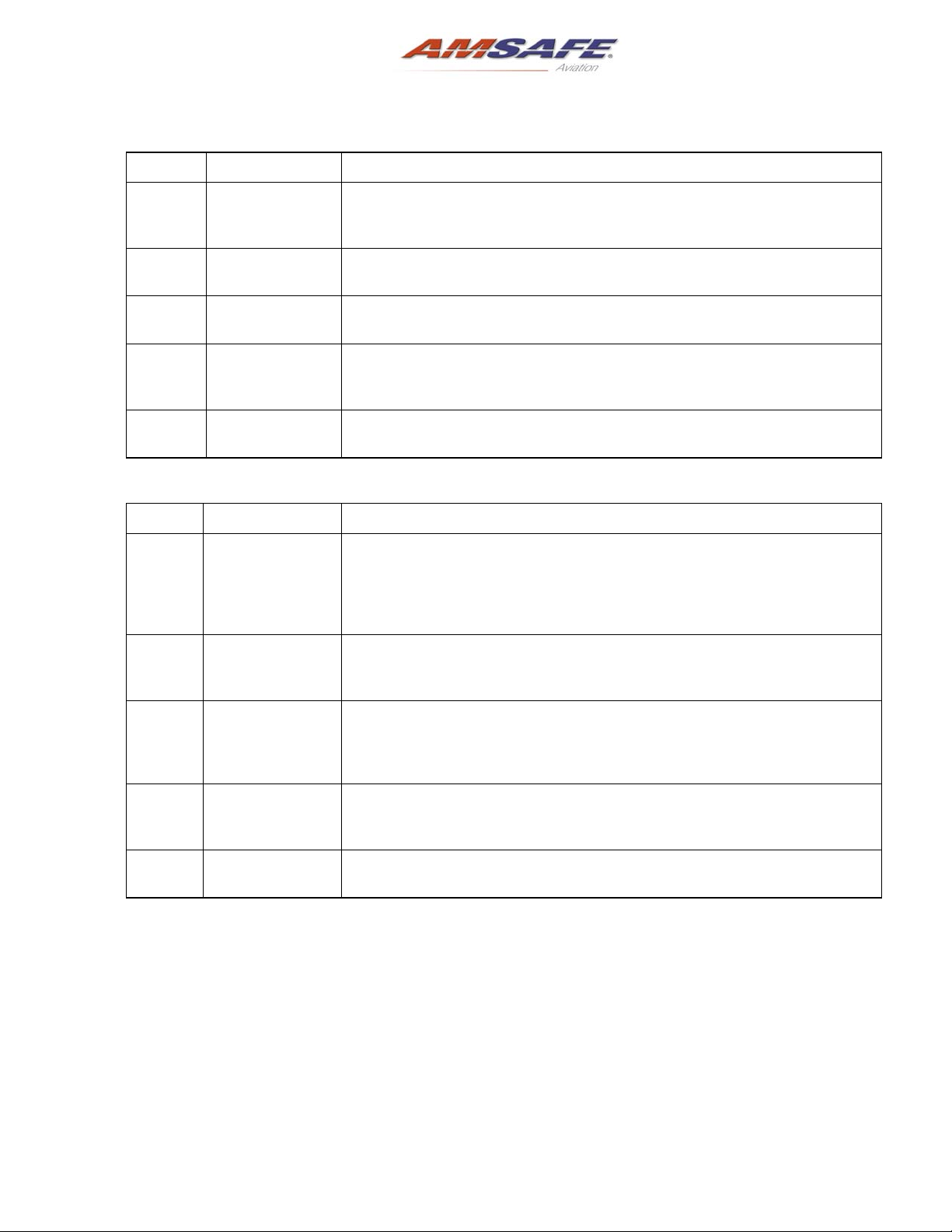

MATERIALS HAZARD RATING CODE

AmSafe Inc. uses the National Fire Protection Association system to identify the different levels of hazards

that are caused by the use of a given material. A Hazard Code identifies three effects of a material on a

person: health (eat, drink, touch, and breathe), fire (when and how it burns), and reactivity (chemical

explosions). Also, each material is given a storage group for safety.

Each code has three numbers and one letter (for example, 130D) as shown in the Hazard Code symbol

below. The three numbers show the hazard levels for health, fire, and reactivity, in that sequence. The

range of each number is 0 to 4. The higher the number, the more dangerous the hazard. You must be careful

with any material that has a Hazard Code with a 2, 3, or 4. The one letter (A thru E) in the code identifies a

specific storage group that is applicable for the material.

If applicable, the materials used for the procedures in this manual are given a Hazard Code. More data on

the health and fire levels is shown in on page 4. Get specific data on a material from the data sheet supplied

by the manufacturer of the material.

POSITION 1: HEALTH HAZARD POSITION 2: FIRE HAZARD

0

1

2

3

4

No important hazard.

Irritant Use with caution.

Hazardous Prevent continued exposure,

inhalation, and contact.

Dangerous hazard Use protective clothing

together with protection to breathe.

Very bad hazard Do not breathe vapor or come

in contact with liquid without approved special

protection.

0

1

2

3

4

Will not burn.

Must increase the temperature above 93.4°C to

burn.

Must increase the temperature above 37.8°C to

burn.

Fire and explosion hazard at ambient

temperature.

Highly dangerous fire and explosion hazard.

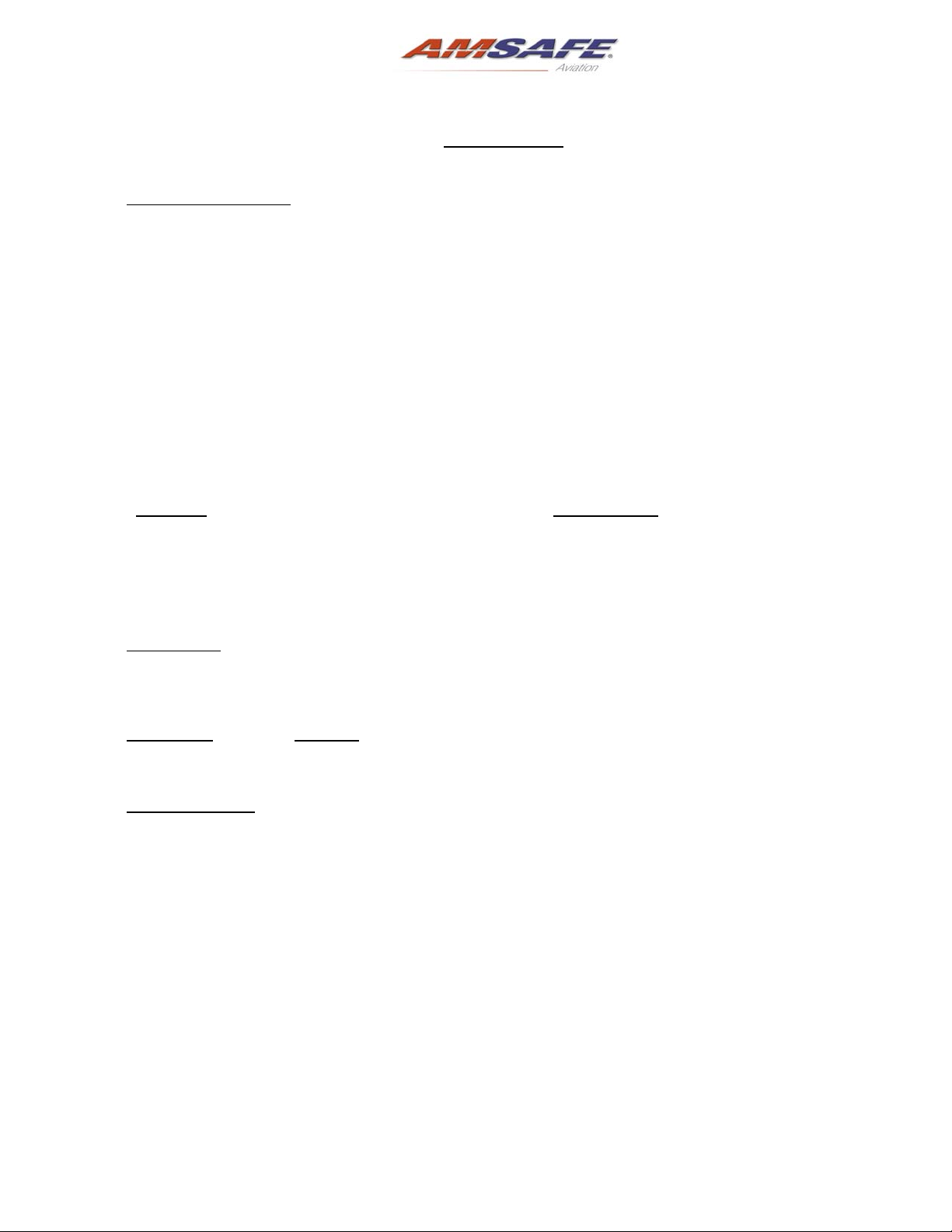

POSITION 3: REACTIVITY HAZARD POSITION 4: STORAGE

0

1

2

3

4

Usually stable.

Unstable if heated.

Violent chemical change is possible.

Dangerous explosion is possible.

Very bad explosion hazard quickly go out of the

area if materials are exposed to fire.

A

B

C

D

E

Acids.

Alkalis, cyanides.

Oxidizing agents.

Chlorinated hydrocarbons, flammable liquids,

materials that are not flammable.

Neutral salts and others.

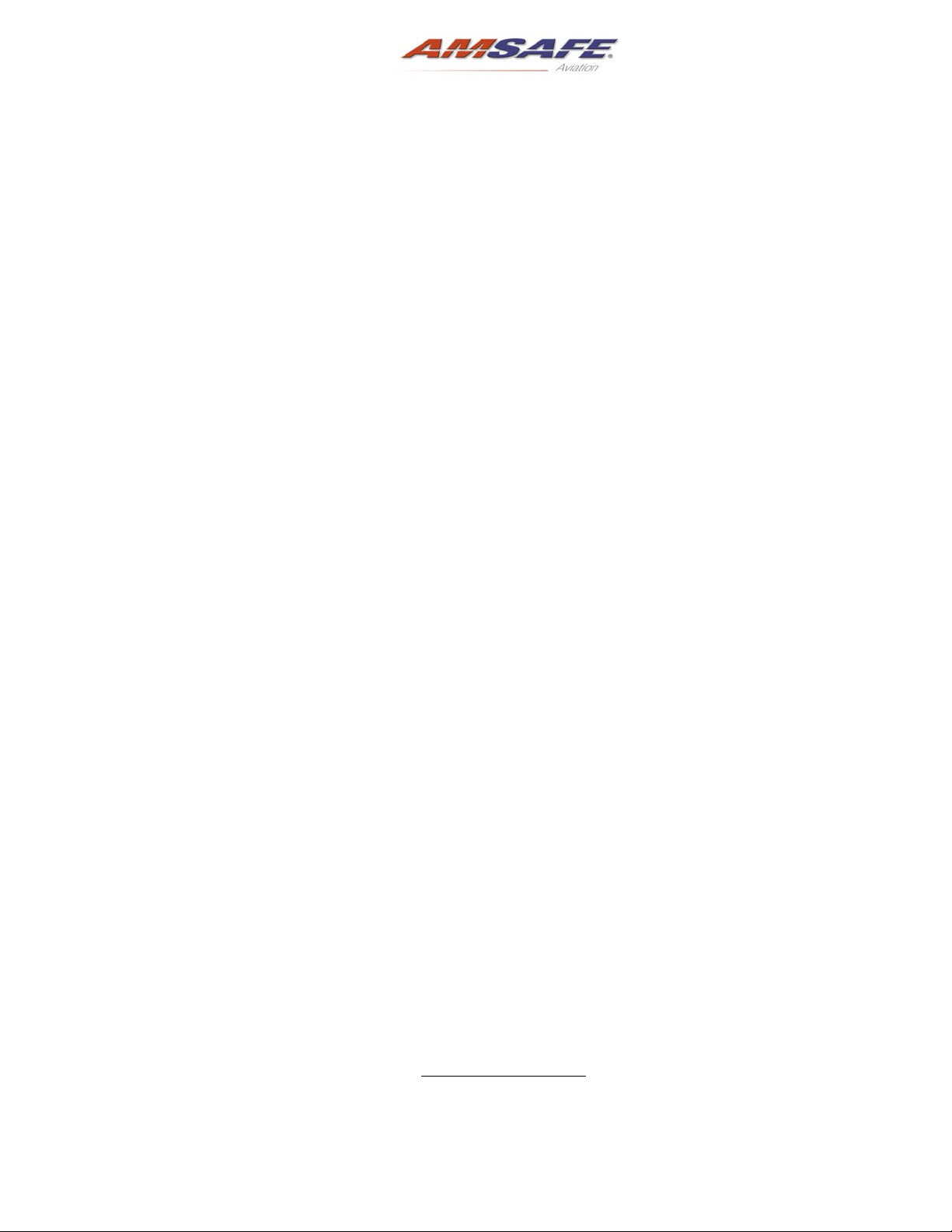

POSITION 3

REACTIVITY

(YELLOW)

POSITION 4

STORAGE

(WHITE)

POSITION 1

HEALTH

(BLUE)

POSITION 2

FIRE

(RED)

The document reference is online, please check the correspondence between the online documentation and the printed version.