Specications Information and Repair Parts Manual 3201-96

3201-250-00 1 6/2015

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the General Operating

Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property damage! Retain instructions

for future reference. AMT reserves the right to discontinue any model or change specications at any time without incurring any obligation.

©2015 AMT Pump Company, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure to do so

voids warranty.

Centrifugal Laundry Tray Pump

Refer to pump manual 1808-634-00 for General Operating and Safety Instructions.

INSTALLATION

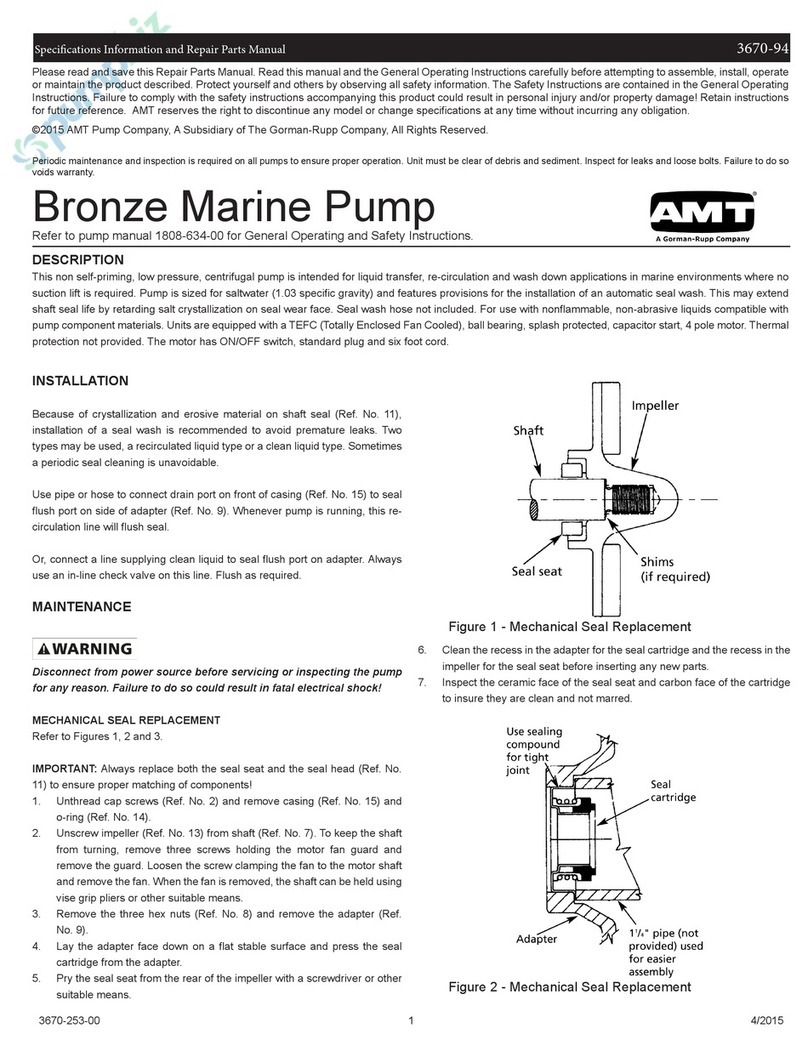

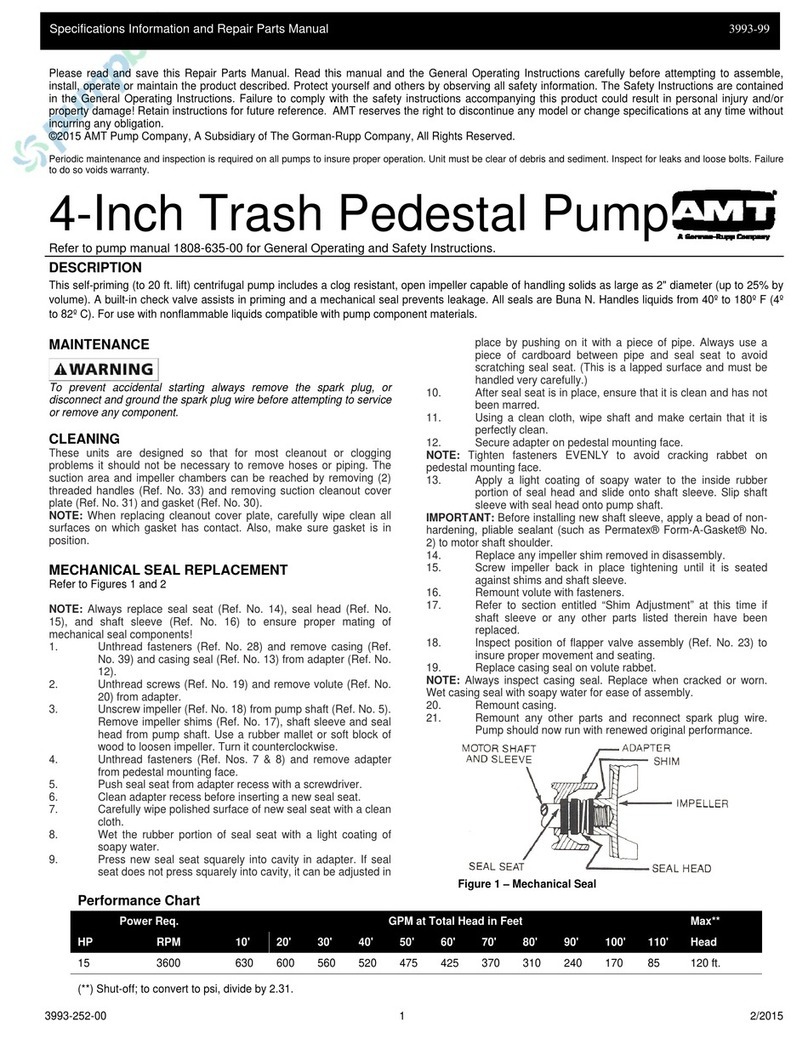

Refer to Figure 1 and proceed as follows:

1. Locate pump as close to the laundry tub as possible. Support the

pump and piping adequately to keep pump and piping from being

strained.

2. Pitch the piping from tub drain to pump suction to avoid air traps.

(Do not use the conventional trap). Keep the pipe-size at least

11/4”. Use pipe dope to avoid joint leakage. Install necessary

piping for pressure switches or any other control devices (not

supplied). Follow manufacturer’s instructions for their installation.

3. Install a check valve on the discharge side to prevent drain-back.

4. Locate check valve below level of bottom of tub.

5. Wire motor by following wiring diagram on nameplate. It is

strongly recommended that this unit is plugged into a GFCI

(Ground Fault Circuit Interrupter). Consult your local electrician

for installation and availability. Be sure unit is grounded (General

Safety Information). If unit is to be controlled by an on and off

switch, install at this time.

6. If laundry water from a washer is discharged into the laundry tub,

it should be ltered. Filtering can be accomplished many ways.

An easy way is by taking an old pair of panty hose, putting one

leg into the other, and then putting it on the end of the washer

discharge hose with a rubber band. Most of the panty hose

should be lying in the laundry tub. Eventually, the panty hose will

become full of lint and a hole will develop. The panty hose should

then be replaced.

7. Installation is now complete.

NOTE: To prevent accidents, locate motor in a suitable (ventilated)

enclosure, or guard all moving parts and ventilation openings.

OPERATION

Turn unit on by either plugging pump in, turning switch on, or if unit

is installed with an automatic device, (not supplied) it will activate

itself as well as turn itself off. On units without automatic devices, it is

necessary to shut pump off when water stops draining out of the tub

(last couple of inches). The pump has become air bound. After a few

seconds, when the water has gone down, turn unit on again. The unit

may have to be turned on and off a few times to completely drain tub.

This is normal. When water has been completely pumped out of the

tub, turn pump off immediately.

MAINTENANCE

Disconnect from power source before servicing or inspecting

the pump for any reason. Failure to do so could result in fatal

electrical shock!

MOTOR

Dirt accumulations can cause motor overheating and a re hazard.

Remove dirt accumulations from the motor, especially in and around

vent openings by vacuuming.

Periodically inspect the installation. Check for dirt accumulations;

unusual noises or vibration; overheating; worn or loose couplings,

sheaves and belts; high motor current; poor wiring or overheating

connections; loose mounting bolts or guards.

DESCRIPTION

This centrifugal laundry tray pump is designed for gravity-feed pumping operations. Unit can handle laundry water or other nonammable, non abrasive uids

compatible with pump construction. Pump is equipped with mechanical seal (carbon face with Buna-N seal cartridge), cast aluminum body and impeller, and

a split-phase motor. This is a manual unit, no controls are supplied. Unit does not come supplied with any type of switch or control device to turn unit on or off.

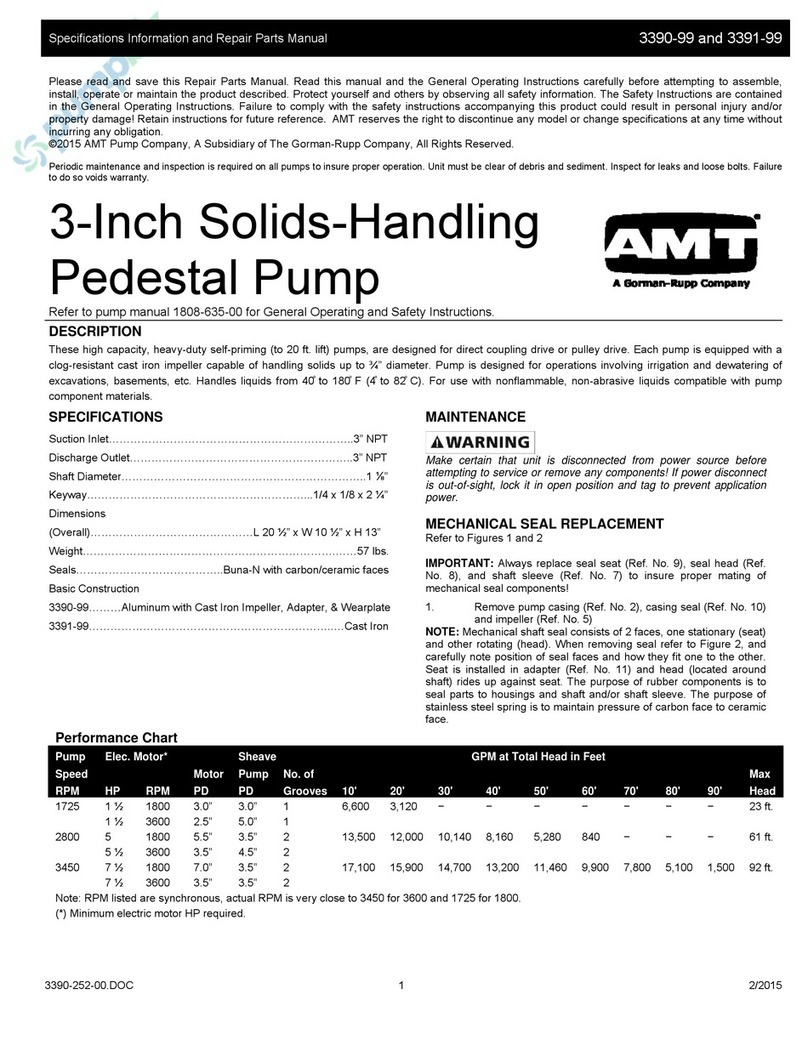

Figure 1 - Typical Installation Figure 2 - Location of Bearings