©2003-2021 Anago Ltd

CONTENTS

Frequently Asked Questions .................................................................................................................. 3

1. Introduction .................................................................................................................................... 5

Anago Limited ......................................................................................................................... 5

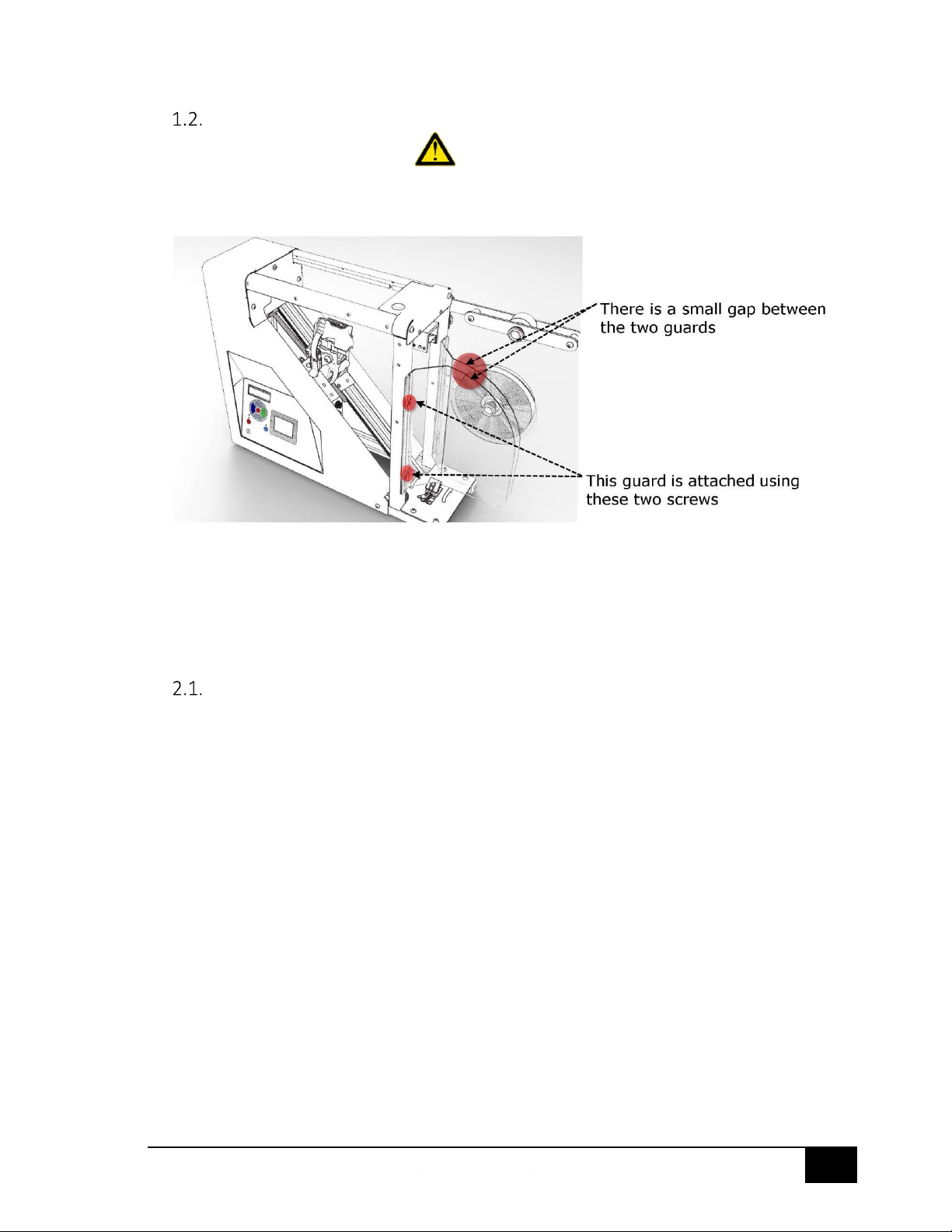

Safety ...................................................................................................................................... 6

2. Initial setup ..................................................................................................................................... 6

Software Installation ............................................................................................................... 6

Test Media .............................................................................................................................. 7

Connecting to a PC or Laptop ................................................................................................. 8

Operating Modes .................................................................................................................... 8

Calibration ............................................................................................................................... 9

Operation ...................................................................................................................................... 12

3.1. Basic Operations ................................................................................................................... 12

3.2. Keypad Functions .................................................................................................................. 13

3.3. Rapid Clamp .......................................................................................................................... 14

3.4. Running a Test ....................................................................................................................... 16

Test Results ................................................................................................................................... 18

4.1. PC Mode ................................................................................................................................ 18

4.2. Stand-Alone Mode ................................................................................................................ 21

Data management ........................................................................................................................ 22

5.1. Viewing Previous Results ...................................................................................................... 22

5.2. Editing Test Information ....................................................................................................... 24

5.3. Exporting Test Results ............................................................................................................. 0

5.4. Backing up, Restoring and Importing Data ........................................................................... 25

Troubleshooting and maintenance .............................................................................................. 26

6.1. Caring for Your Machine ....................................................................................................... 26

6.2. Spare Parts ............................................................................................................................ 27

6.3. Software Updates ................................................................................................................. 27

6.4. Machine Components ........................................................................................................... 28

6.5. Specifications ........................................................................................................................ 30