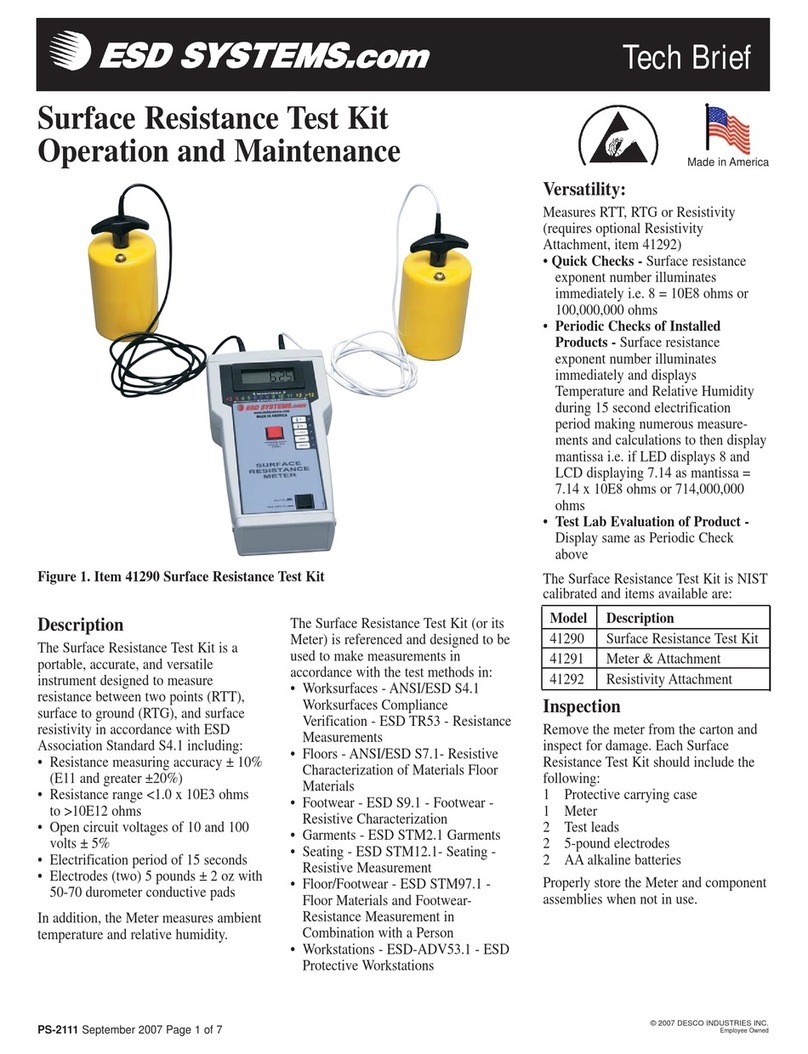

WRIST STRAP TESTING WITH

MODEL 41220

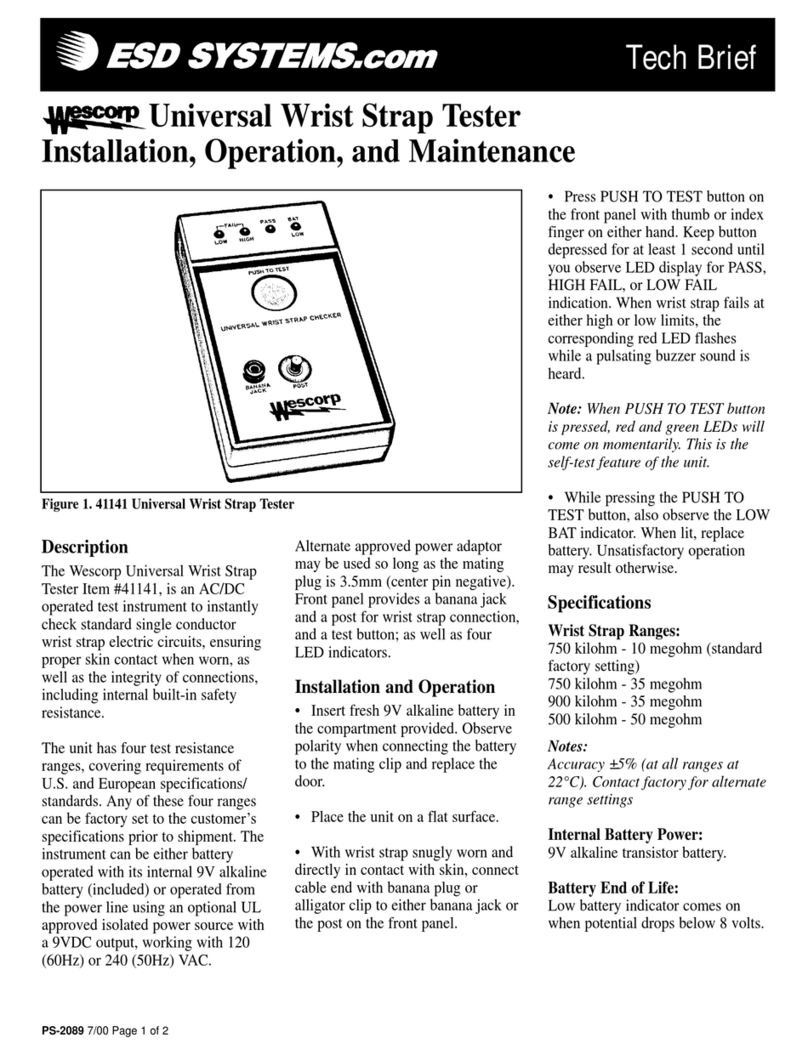

This test safely checks that a

continuous path between the

operator, wrist strap and coil cord

exists.

A. While wearing the wrist strap

snugly on wrist, plug the banana

plug end of the cord into the jack on

the face of the unit.

B. Switch toggle switch toward

“WRIST STRAP”.

C. Touch the test button so that the

unit activates. Hold for 2-3 seconds

while flexing coil cord area near

resistor. Audio “chirping indicates

intermittents. Note: Often the initial

intermittency will be failure of strain

relief connection to resistor as

simulated by ESD S1.1-1998

paragraph 5.7 Bending Life Test.

Note: DO NOT TOUCH ANY

OTHER METAL WHILE

PERFORMING TEST.

Figure 2. Testing of wrist strap

grounding assemblies.

D. Lighting of the green “PASS”

LED indicates that the wrist strap

and ground cord assemblies are

functioning properly.

E. If either “FAIL LO” or “FAIL

HI” LEDs light, the wrist strap

wearer should investigate the cause

of the failure.

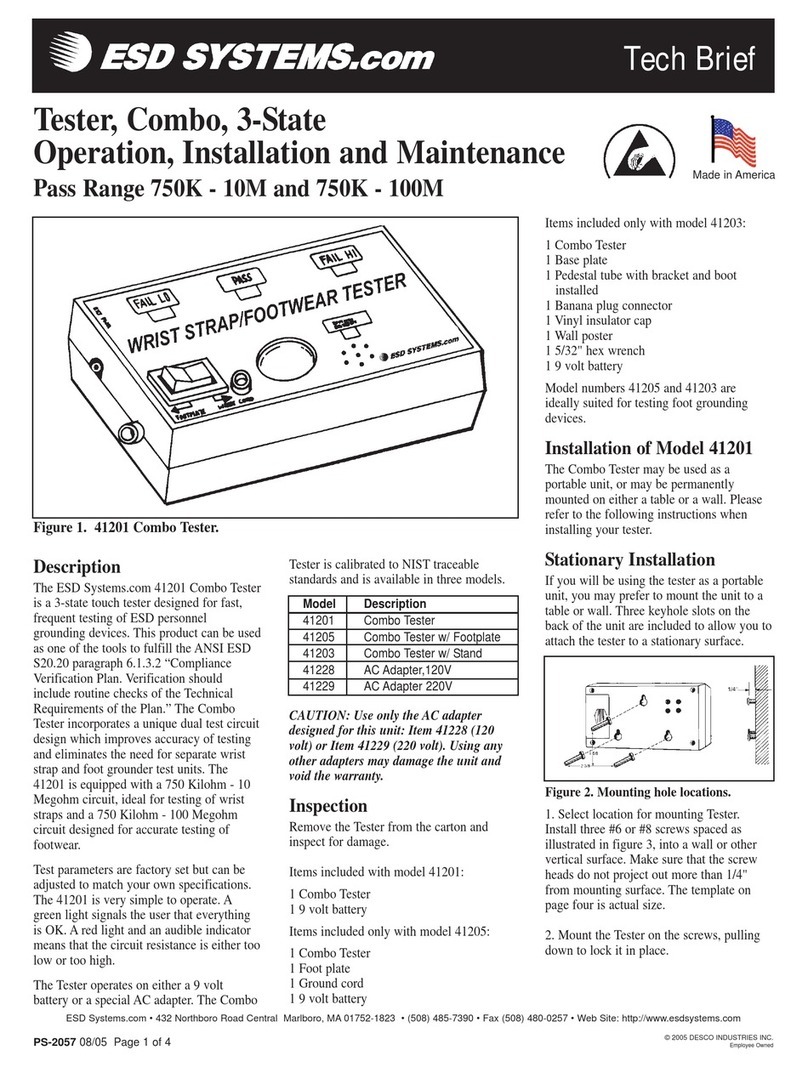

TESTING FOOT GROUNDING

DEVICES WITH MODEL 41220

AND 41213 FOOTPLATE

Conductive shoes or foot grounders

should be worn on both feet. Test

each foot separately to ensure proper

operation and complete protection.

A. Place the Footplate on the floor

in front of the Multi-Range Tester.

B. Plug the plate’s ground cord into

the jack on the left hand side of the

unit.

Figure 3. Testing foot grounding

devices with the 41220/41213

C. Switch toggle switch to “FOOT

STRAP” OR “SHOE”, as

appropriate.

D. Place one foot on the plate. If the

floor is conductive, you may need to

lift the foot you are not testing off of

the floor during this test. Make sure

there is no cord plugged into the

“WRIST STRAP” jack.

E. Touch the test button so that the

unit activates. Hold down for 2-3

seconds.

F. Lighting of the green “PASS”

LED indicates that the foot ground

assemblies are functioning properly.

G. If either “Fail LO” or “Fail HI”

LEDs light, the wearer should

investigate the cause of the failure.

H. Repeat steps C through G with

other foot.

ASSEMBLY OF THE 41226

STAND

The 41226’s rugged steel pedestal

tube is powder coated in a non-

conductive white finish that helps to

prevent false readings if contacted

by skin or loose smocks.

Figure 4. Attaching pedestal to

baseplate

Assembly

A. Remove 3 screws from baseplate.

B. Position pedestal on the baseplate

with the Tester mounting bracket

sloping toward the operator. Attach

pedestal to baseplate using the three

screws provided. Tighten with hex

wrench provided.

B. Attach poster to the wall at eye

level in front of the Tester location.

C. Attach ring terminal end of small

cord supplied under thumb screw.

PS-2094 Page 2 of 4 © 2005 DESCO INDUSTRIES INC.

Employee Owned