BEAMEX TC305 User manual

Service manual for

TEMPERATURE CALIBRATOR

TC305/TC303

Dear user,

We have made every effort to ensure the accuracy of the

contents of this manual. Should any errors be detected, we

would greatly appreciate to receive suggestions to improve the

quality of the contents of this manual.

The above not withstanding, we can assume no responsibility

for any errors in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without

any further notice.

For more detailed technical data about the Service manual for

TC305/TC303, please contact the manufacturer.

© Copyright 1997

OY BEAMEX AB

P.O. Box 5

68601 Pietarsaari

FINLAND

Tel +358 - 6 - 7840111

Fax +358 - 6 - 7840404

E-mail: [email protected]

Internet: http://www.beamex.com

8830100 / SETC305 / 912417

CONTENTS

PART A. FUNCTIONAL DESCRIPTION

1 GENERAL ................................................................................................................................A - 1

2 SECTION A..............................................................................................................................A - 2

3 SECTION B..............................................................................................................................A - 3

PART B. SERVICE

1 WARNING DURING OPERATION......................................................................................... B - 1

2 HARDWARE ERROR MESSAGES ....................................................................................... B - 2

3 SERVICE, TROUBLESHOOTING AND REPAIR.................................................................. B - 4

3.1 Disassembling and reassembling the calibrator......................................................... B - 4

3.2 Updating the software version....................................................................................... B - 5

3.3 Installing software options............................................................................................. B - 5

3.4 Replacing the battery pack............................................................................................. B - 6

3.5 Hardware troubleshooting.............................................................................................. B - 6

3.5.1 Front assembly.............................................................................................................B - 7

3.5.1.1 Display and keypad board......................................................................................B - 7

3.5.1.2 Battery pack............................................................................................................B - 7

3.5.1.3 Power supply board................................................................................................B - 8

3.5.2 Analog i/o assembly .....................................................................................................B - 9

3.5.3 Processor boards .......................................................................................................B - 10

3.5.4 Optional 24V supply board.........................................................................................B - 10

PART C. CALIBRATION

1 GENERAL ............................................................................................................................... C - 1

2 EQUIPMENT REQUIRED FOR CALIBRATION.................................................................... C - 1

3 PREPARATIONS BEFORE CALIBRATION.......................................................................... C - 3

4 SECTION B MEASUREMENTS............................................................................................. C - 4

5 SECTION A MEASUREMENTS............................................................................................. C - 6

6 RESISTANCE SIMULATION.................................................................................................. C - 8

7 INTERNAL REFERENCE JUNCTION COMPENSATION.................................................. C - 10

7.1 Calibration with thermocouple..................................................................................... C - 11

7.2 Calibration with a thermometer ................................................................................... C - 12

8 CALIBRATION DATE........................................................................................................... C - 13

9 AUTO CALIBRATION OF GENERATION RANGES........................................................... C - 14

10 CALIBRATION PERIOD..................................................................................................... C - 15

PART D. SERIAL COMMUNICATION

1 GENERAL ............................................................................................................................... D - 1

2 TECHNICAL SPECIFICATIONS ............................................................................................ D - 2

2.1 Flow control (XON/XOFF)............................................................................................... D - 2

2.2 Checksum......................................................................................................................... D - 2

2.3 Acknowledgment (ACK/NAK) ........................................................................................ D - 3

2.4 Line terminators (CR/LF)................................................................................................ D - 3

3 COMMANDS........................................................................................................................... D - 4

3.1 Interface configuration and control............................................................................... D - 5

3.1.1 Communication control................................................................................................ D - 5

3.1.2 Line termination........................................................................................................... D - 5

3.1.3 Control of sent measurement/generation readings..................................................... D - 6

3.1.4 Use of status codes..................................................................................................... D - 6

3.1.5 Formatting of readings................................................................................................. D - 7

3.2 Device configuration....................................................................................................... D - 8

3.2.1 A-section (upper display) electrical unit selection....................................................... D - 8

3.2.2 A-section temperature / electrical mode selection...................................................... D - 8

3.2.3 Temperature sensor selection..................................................................................... D - 9

3.2.4 Temperature scale....................................................................................................... D - 9

3.2.5 CJ-selection............................................................................................................... D - 10

3.2.6 Generation value setting ........................................................................................... D - 10

3.2.7 Emulation of mechanical switch settings .................................................................. D - 10

3.2.8 B-section (lower display) electrical unit selection ..................................................... D - 11

3.2.9 Local on/off................................................................................................................ D - 11

3.3 Calibration and service................................................................................................. D - 12

3.4 Commands for key emulation / inquiry....................................................................... D - 13

3.5 Other standard commands........................................................................................... D - 14

3.5.1 System details ........................................................................................................... D - 14

3.5.2 Set/get date ............................................................................................................... D - 14

3.5.3 Display message....................................................................................................... D - 15

3.6 Special commands........................................................................................................ D - 16

APPENDIXES

APPENDIX A: STATUS CODE / ERROR MESSAGES IN SERIAL COMMUNICATION .......X - 1

APPENDIX B: MEASUREMENT PRINTOUT FORMAT ...........................................................X - 2

APPENDIX C: ALGORITHMS....................................................................................................X - 4

APPENDIX D: PC106P RS-232 SAVEABLE OPTIONS..........................................................X - 4

FUNCTIONAL

DESCRIPTION

TC305/TC303 - Functional Description A- 1

1 GENERAL

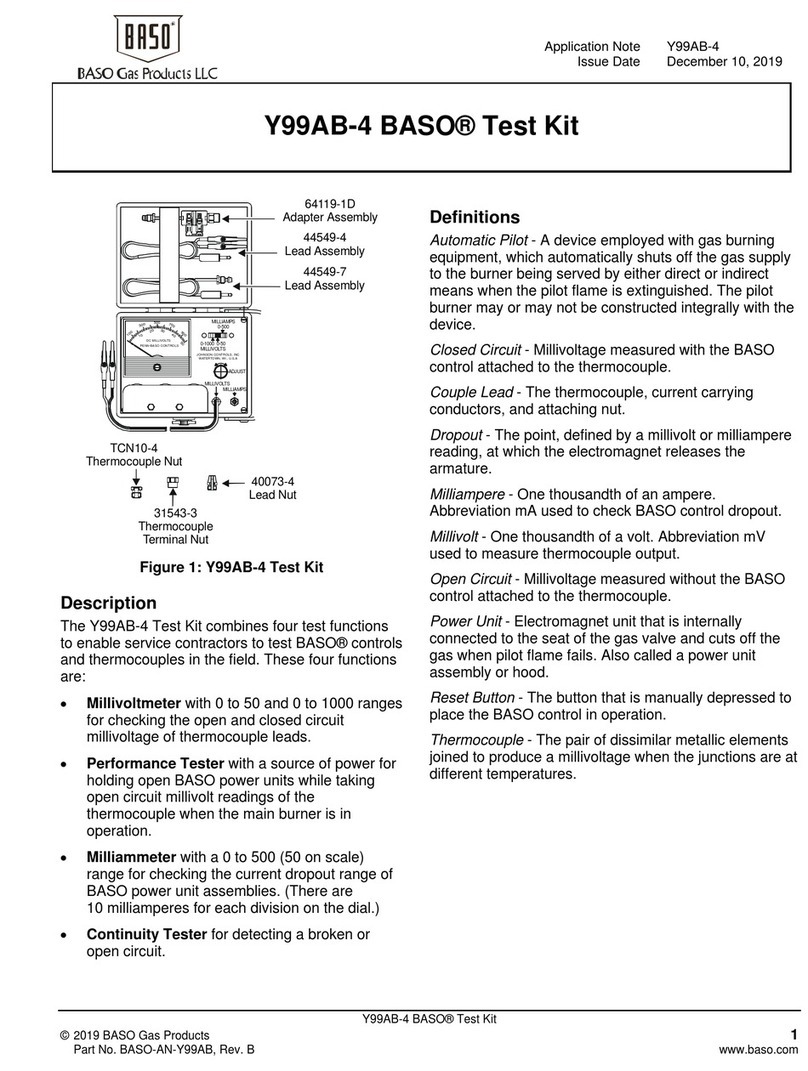

The functions of TC305/TC303 temperature calibrator are divided in two sections.

The left side of the connection panel and the upper display constitute the

Measure/Generate section which is called the A-section. The right side of the

connection panel and the lower display constitute the Measure section, called

here the B-section.

A- 2TC305/TC303 - Functional Description

2 SECTION A

The A-section microprocessor takes care of electrical measurements and

generations/simulations. It also makes all calculations required for temperature

sensor simulations and measurements. It uses one A/D-converter for all these

measurements and one D/A-converter for generations/simulations.

In resistance measurement TC305/TC303 generates the measurement current

and measures the voltage across the resistance. It switches off the current for a

part of the time. This enables compensation of the thermovoltages in the

resistance measurement circuit.

In voltage and current generation TC305/TC303 makes the output with the D/A-

converter and assures the accuracy by continuously measuring the generated

value.

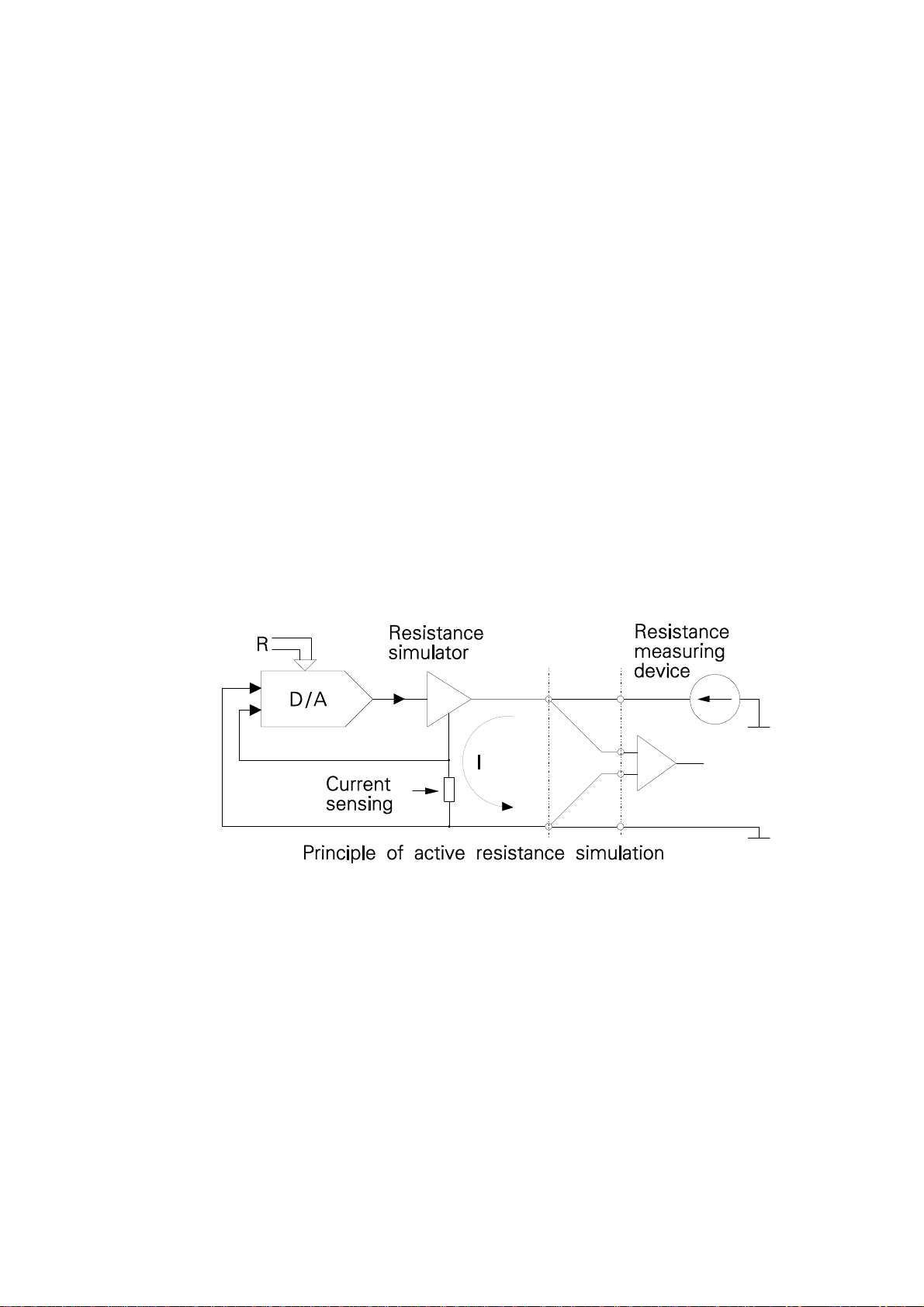

In resistance simulation there should be an external resistance measurement

device measuring the resistance between the TC305/TC303 output terminals.

The D/A-converter detects the measurement current coming from the external

measurement device. It controls the voltage across the resistance output

terminals so that it is in the correct ratio to the detected current. The

microprocessor defines this ratio according to the Ohm's law and the simulated

resistance value.

Theoretically the resistance simulation could be able to simulate the given

resistance also to an AC circuit. In practice, anyhow, it is always too slow to

achieve reasonable accuracy, if the measurement device uses AC supply for

resistance measurement. Fortunately AC measurement of resistance is very

seldom used nowadays.

Some resistance measurement devices - like TC305/TC303 itself - use pulsed

current for resistance measurement. Simulation to these devices is possible with

TC305/TC303. The measurement device should, however, give enough time for

the circuits to settle after switching the current on. This is normally necessary also

because of the inductance and capacitance of the industrial resistance

measurement circuits.

TC305/TC303 - Functional Description A- 3

3 SECTION B

The B-section microprocessor uses another A/D-converter to measure current or

voltage. There are also circuits for switch state detection. There is a galvanic

isolation between the two sections. This enables you to generate the input of an

instrument and simultaneously measure the instrument output.

The B-section microprocessor also carries out the communication with the user

and with the computer via the serial computer interface.

SERVICE

TC305/TC303 - Service B- 1

1 WARNING DURING OPERATION

If you try to use TC305/TC303 in a strange way, it may warn you about it. The

following list explains the used warning messages in detail.

NO TCAL Attempt to start Quick Store or Quick Examine function

when TCAL305 expansion software is not installed.

NO ID No instrument identifier defined.

CLEAR AREA No instrument data in the loaded memory area.

UNDEFD SENSOR Attempt to load instrument data from Data Memory. The

defined sensor type was not known and loading was denied.

If a special sensor is included in the instrument data and the

special sensor is no longer fixed to the defined special

sensor place, the required special sensor arrow is lit.

CONFIG ERROR Attempt to start the Quick Store function with faulty

configuration, e.g. the instrument type is FREE.

SCAN ERROR The actuation or deactuation point of a limit switch out of the

scan limits or scan limits out of the generation/simulation

range of the calibrator.

NOT SAVED Attempt to change the contents of the Working Memory

without saving the results of the latest Quick Store to the

Data Memory.

CANCEL STORE Escaping from Quick Store before altering the contents of

the Working Memory.

DATA LOST TC305/TC303 has lost its configuration data, instrument

data and calibration results due to the missing RAM backup

voltage. The obvious reason is, that the battery has been

disconnected for a while or empty battery has not been

recharged in time. Switch the calibrator off and check the

battery wiring, recharge the battery or replace it if necessary.

If the error remains, send TC305/TC303 to Beamex or

representative for repair.

B- 2TC305/TC303 - Service

DATE LOST TC305/TC303 calendar/clock has lost the date and time due

to the missing backup voltage. The obvious reason is, that

the battery has been disconnected for a while or empty

battery has not been recharged in time. Check the battery

wiring, recharge the battery or replace it if necessary. Enter

the new date and time as explained in part C of this manual.

If the error remains, send TC305/TC303 to Beamex or

representative for repair.

CALIBR SOON According to the given calibration period, you should soon

recalibrate the TC305/TC303 calibrator.

NO CAL DATA This message is used in new devices before the initial

definition and calibration. It should not come in sold devices.

However, if it comes, there is fault in the EEPROM memory.

TC305/TC303 has lost all calibration data. Do not use it for

calibration purposes. Send it to the manufacturer for repair.

NO DATA Attempt to use the Quick Examine function when the

Working Memory is empty.

NO FREQ MODULE The instrument to be calibrated requires a frequency module

or the settings of the frequency module does not correspond

to the requirements. The inverted arrows in TC305/TC303

display the settings needed for the operation. This applies

for software versions 1.31 and later. In earlier software

versions the message was "BAD FRQ UNIT x".

TC305/TC303 - Service B- 3

2 HARDWARE ERROR MESSAGES

If TC305/TC303 detects errors in its internal functions, it denies all operations and

shows an error code:

ERROR

CODE n

The error code helps to decide, how to correct the error.

Error codes:

1The A-section microprocessor doesn't answer when called from the

B-section.

2Fault in the B-section analog part.

3Checksum error in EEPROM memory.

4Fault in the A-section analog part.

5Error in the A-section digital part.

6Error in the clock/calendar circuit.

7The watchdog circuit detected fault in operation during previous use.

8Errors in communication between A- and B-sections.

9Software option data in EEPROM corrupted.

10 According to A/D-converter readings, the A-section analog part is faulty.

The messages give some idea, where the error might be. You can't, however,

make any absolutely sure conclusions of them. Error codes 2,3,4,9 and 10

normally show that the error is in the analog i/o assembly. Error codes 6 and 7

mean that the main processor board is faulty. Obvious cause for the error code 5

is on the temperature processor board. Errors 1 and 8 may be caused by a fault

on either one of the two processor boards. In all cases the actual fault can be in

cabling between the boards. In some cases the fault is said to be in the analog i/o

assembly but it actually is on one of the processor boards or vice versa. Fault on

the power supply board can cause practically any malfunction or error message.

B- 4TC305/TC303 - Service

3 SERVICE, TROUBLESHOOTING AND REPAIR

If you can't switch the calibrator on at all, the most obvious fault is empty battery.

If charging doesn't help, check the battery voltage from the battery terminals. If

the battery is ok, but you still can't start the calibrator, the fault is obviously in

internal cabling or on the main processor board. If your device stops and shows

an error code, write down the shown code number and switch the calibrator off.

Wait five seconds and switch the calibrator on to see, if the error remains. If the

error remains or repeats later, see the following chapters for more help. Only

board level service is explained. Component level trouble shooting would require

detailed knowledge both of the hardware and of the software.

If the fault is obvious or if you can locate it using the information given in this

manual, you can perhaps repair it locally. Otherwise, send the device to the

manufacturer or to the representative for repair. In case of warranty repair, always

send the device to us or to our representative. Most representatives can carry out

board level trouble shooting and replace faulty boards or units.

3.1 Disassembling and reassembling the calibrator

The calibrator must be taken apart in case of software update, read/write memory

installation, battery replacement or hardware trouble shooting. The following steps

are required to disassemble TC305/TC303:

∗ Switch off the calibrator.

∗ Loosen the four screws on the bottom of the calibrator.

∗ Carefully lift the rear of the cover and remove the cover.

∗ Remove the handle and the handle springs.

∗ Remove the two screws holding the front assembly.

∗ Loosen the front assembly cable connectors from the processor boards

below it and from the analog i/o assembly.

∗ Remove the four screws on the front and rear of the analog i/o assembly.

∗ Lift the analog i/o assembly and loosen its cable connectors from the

processor boards.

Reassembling requires opposite steps. If the front assembly has been removed,

TC305/TC303 looses date, time and all data stored in the read/write memory.

This includes Working Memory, Data Memory and all configuration settings.

Calibration data as well as installation of software options do not change,

because they are stored in the non-volatile EEPROM memory. Setting of date,

time and all configurations is explained in part C of the instruction manual. After

disassembly, TC305/TC303 may show error message 'ERROR CODE 7'. If this

happens, switch the unit off for 5 seconds and try to switch on again.

Note:

When disassembling a TC305/TC303, all special sensor definitions will be

TC305/TC303 - Service B- 5

lost. After reassembling, refer to chapter "Special sensor definition" in

part C of the Instruction manual to fix your additional sensor to a special

sensor number.

3.2 Updating the software version

TC305/TC303 software is stored in two EPROM memories, one on each

processor board on the bottom of the calibrator. The left side (front view)

processor board is named 'main processor board' and the right side processor

board is 'temperature processor board'. The EPROMs are labeled 'Main

Processor' and 'Temp. Processor' respectively. To install a new software version,

follow the updating instructions delivered with the new EPROM(s).

3.3 Installing software options

To be able to install software options, you must purchase the license for the

option from us. The license is delivered in form of security codes. To be able to

generate the codes, we need the serial number of the calibrator as well as the

serial number of the analog i/o assembly of the calibrator.

To read the serial numbers, select the configuration menu entry

CONF

<OTHERS> (quick select qCONF qSTO)

To the prompt

C.CODE?

enter the code

101 ENT

For example the display

C.330

E.10234

means that the serial number of the calibrator is 330 (should be the same as

marked on the connection panel) and the serial number of the analog i/o

assembly is 10234.

Write the numbers on paper and press qESC to exit. Contact us for further

operations.

B- 6TC305/TC303 - Service

3.4 Replacing the battery pack

If you recharge the battery regularly, it can be used years without replacement.

When the battery gets old, its capacity decreases and it can not be used long

enough between recharges.

To replace the battery pack:

∗ Remove the cover of the calibrator.

∗ Open the screws of the battery pack cover and remove the cover.

∗ Loosen the battery pack wire connectors from the power supply board.

∗ Install the new battery pack in reverse order.

The battery replacement should be done with the battery charger connected to

prevent loss of data stored in the read/write memory. Otherwise TC305/TC303

looses date, time and all data stored in the read/write memory. This includes

Working Memory, Data Memory and all configuration settings. Calibration data as

well as installation of software options do not change, because they are stored in

the non-volatile EEPROM memory. Setting of date, time and all configurations is

explained in part C of the instruction manual. After disassembly, TC305/TC303

may show error message 'ERROR CODE 7'. If this happens, switch the unit off for

5 seconds and try to switch on again.

3.5 Hardware troubleshooting

If TC305/TC303 doesn't function properly, we recommend that you send it to us

for reparation. Board or module level trouble shooting can be done also by other

qualified service personnel. However, reparations by others than Beamex during

the warranty period invalidate the warranty.

If you have another functional TC305/TC303, you can relatively easy find the

faulty part of the calibrator. Something can also be concluded from the symptoms

without replacement parts.

TC305/TC303 - Service B- 7

3.5.1 Front assembly

3.5.1.1 Display and keypad board

Fault on the display and keypad board is obvious, if

∗ The calibrator functions, but some display segments never show.

∗ Display back light or some parts of it never function.

∗ Some keys never function. In this case the fault can be on the main

processor board or in cabling, too.

∗ Some keys stack. The obvious reason is that some dust or liquid has

penetrated into the keypad.

If the malfunction of the keys or displays depends on the task that the calibrator is

carrying out, the fault is more obviously on the main processor board.

3.5.1.2 Battery pack

If the calibrator can not be used long time enough after recharge, check first that

the fault is not in the recharging. After sufficient recharge time disconnect the

charger and after a few minutes measure the battery voltage (See Instruction

Manual part C, Chapter 3). The reading should be about 100%. If the value is too

low, check the charger and the power supply card.

If the batteries can be charged to full charge but the using time is considerably

shortened, the obvious reason is faulty battery pack. The battery may also

damage so that the calibrator cannot be switched on at all. In such case, remove

the calibrator cover and measure the battery voltage. With fully charged battery

the voltage should be around 8.5V at room temperature, if the charger has not

been connected for 15 minutes and the calibrator is not switched on.

Warning!

Avoid short circuiting the battery terminals, the short circuit current may

cause burns, battery damage or even fire. See also warning in the

Instruction Manual Part A, Chapter 2.3.

B- 8TC305/TC303 - Service

3.5.1.3 Power supply board

The functions on the power supply board include battery charge control and

generation of supply voltages. The power supply construction is quite complicated

and all you are recommended to do is to measure the output voltages. For the

measurements you must connect all cables coming from the power supply card

and switch the calibrator on. The most important voltage is marked 'G' on the

following figure. If it is about 25.5V, it is obvious that all other voltages are right,

too. If your calibrator has the 24V supply option, measure the 24V supply output.

If it is right, you can be quite sure that the other voltages are right, too.

A,B = 15V C...F = 5V G = 25.5V

The calibrator sections A and B should be galvanically isolated from each other.

To check this, switch the calibrator off and measure the DC-resistance between

the CJ-block minus terminal and the section B black terminal. The value should

be more than 10 megaohms. If the resistance is lower, the fault can be in the

power supply, in the i/o-assembly, in one of the processor boards or in cabling.

Warning!

Use an ordinary ohm meter, not a high voltage isolation meter. The galvanic

isolation between the sections is for functional purposes only.

TC305/TC303 - Service B- 9

3.5.2 Analog i/o assembly

The analog i/o assembly consists of three cards, but they should only be replaced

as one unit. If one of the cards or some components were replaced, the entire unit

should be redefined in the factory, otherwise the required accuracy can not be

achieved. On the other hand, all components related to calibration are in the

analog i/o assembly. This means that calibration is not required if one analog i/o

assembly is transferred from one calibrator to another.

For the communication and calibration security purposes, the calibrator serial

number is stored in the EEPROM of the calibrator. It is recommended that the

stored serial number is the same as marked on the connection panel. Because

the EEPROM circuit is part of the analog i/o assembly, the numbers remain equal

if you replace the analog i/o assembly together with the connection panel.

If you replace the three analog cards only, you should change the serial number

stored in the EEPROM to the same as marked on the connection panel.

To check the stored serial number of the calibrator as well as the serial number of

the analog i/o assembly installed in the calibrator, select the configuration menu

entry CONF

<OTHERS> (quick select qCONF qSTO)

To the prompt

C.CODE?

enter the code

101 ENT

For example the display

C.330

E.10234

means that the serial number of the calibrator is 330 and the serial number of the

analog i/o assembly is 10234. If the calibrator serial number differs from the one

marked on the connection panel, write the displayed numbers on paper and press

qESC to exit.

If the calibrator serial number was not the one marked on the connection panel,

we recommend you to change the stored number. Tell us the displayed serial

numbers for the calibrator and for the analog i/o assembly as well as the serial

number marked on the connection panel. We will give you orders, how to change

the serial number without losing the installed software options.

If TC305/TC303 doesn't measure or generate/simulate properly, a fault in analog

i/o assembly is most obvious. If the only problem is a too large calibration error,

try to correct it by calibration (see part C of this manual).

B- 10 TC305/TC303 - Service

3.5.3 Processor boards

The two processor boards are located on the bottom of the calibrator. The main

processor board is on the left side and the temperature processor board is on the

right side (front view).

Fault on a processor board may cause many different symptoms. It may stack

while showing the 'SELF TEST' prompt, or before showing any special display. It

may switch off automatically without any obvious reason or you may even be

unable to switch it off at all.

If processor fault occurs only once, it may be result of an extremely strong

interference from other electrical circuits or devices. If the fault repeats often, the

faulty processor board must be replaced.

If you can't switch the calibrator off, loosen one of the battery wires from the

power supply board and loosen the battery charger from the calibrator. When you

reconnect the battery wire, you should be able to switch the calibrator on again.

When the batteries have been disconnected, TC305/TC303 loses the contents of

the read/write memory as well as the real time clock time and date.

3.5.4 Optional 24V supply board

If you have the 24V option and the calibrator works otherwise right, but there is no

24V output, the fault is on the 24V option board (or in cabling).

CALIBRATION

This manual suits for next models

1

Table of contents

Other BEAMEX Test Equipment manuals