Clegg Hammer Impact Soil Tester User manual

2022 Manual

CLEGG HAMMER

MANUAL 4.5kg

CleggHammer.com

CLEGG HAMMER MANUAL

Page 1

CLEGGHAMMER.COM

Table Of Contents

System Description 5

Hardware 7

Device Parts 7

Specifications 7

Precautions 7

Control: Power 10

Control: Hammer Connection 11

Control: Operational Check 12

Operational Check Procedure 13

Hammer Drop Procedure 14

Performing a Clegg Impact Test 15

Compaction Control 15

Impact Control 15

Custom Protocols 16

Testing Procedure 18

Standard Drop Height 19

ASTM and Australian Standards 19

Hardware Warranty 19

CLEGG HAMMER MANUAL

Page 2

CLEGGHAMMER.COM

Clegg Control App 21

What is New? 22

Connect a Device 22

App Settings 23

Contact Support 23

Drop Modes 24

Quick Testing Mode 24

Setting Up a Quick Test 24

Create a Session 25

Performing a Drop 25

Adding a Drop Location 26

Advanced Testing Mode 26

What is a Drop Site? 27

What is a Drop Location? 27

Setting up an Advanced Test 28

Create a Session 29

Selecting a Drop Location 29

Performing a Drop 29

VIEWING RESULTS 30

Saving Session Scores 30

CLEGG HAMMER MANUAL

Page 4

CLE GG HAMMER.COM

CLEGG HAMMER MANUAL

Page 5

CLE GG HAMMER.COM

The Clegg offers a rapid, simple, and relatively inexpensive assessment of the

strength and stiffness properties of a variety of soils, aggregates, and synthetic

materials. The impact test result reflects and responds to characteristics that

influence strength. Such influences include material type, grading, layer thickness,

density, moisture condition, and possibly the condition of the underlying layer. With

all things being equal regarding material type and layer thickness and the nature of

the support base, the primary influences are the density and/or moisture condition of

the material. The CIV may be used to observe changes in strength/stiffness for a

material with the changes in compactive effort, density, and moisture content.

When the hammer strikes the soil surface, a precision accelerometer mounted on

the hammer feeds its output to a Control Unit, which sends a digital readout to a

handheld tablet. A drop or sequence of drops of the hammer constitutes one test

called a Clegg ImpactValue (CIV).

Dr. Baden Clegg developed the Clegg Impact SoilTester while working for the

Department of CivilEngineering at the University of Western Australia in the 1970’s.

The Clegg Hammer is an easy-to-use device consisting of two basic components: a

flat- ended cylindrical mass (the hammer) and a guide tube.

System Description

CLEGG HAMMER MANUAL

Page 6

CLE GG HAMMER.COM

CLEGG HAMMER MANUAL

Page 7

CLE GG HAMMER.COM

Precautions

Specifications

Device Parts

Hammer • Guide Tube • Control Unit • Internal BNC coaxial cable • 12x12 inch foam

Calibration Pad • Charger • Storage Case • Tablet with Clegg Control App (available in

the Google Play store and Apple App store)• Silicone Testing Ring• International set of

plugins for global outlets• GPS enabled Android tablet• Protective tablet case with

lanyard

ACCESSORIES • Cart (10 kg model)• Android Tablet• Carrying Case• Global set of

electrical plugin adapters

Model - Maximum Gravities (g) - Maximum CIV’s

96051 4.5 kg - 1200g - 120civ

• Battery Life: 12 Hours

• 3.7V/1.75Ah Lithium Ion Battery

• Complete Charge in 3 hours

• Results displayed/stored on tablet-based app

The Clegg Impact Soil Tester has been designed to be easy-to-use and provide

years of service. Though primarily used outdoors in many types of situations, it is a

scientific instrument incorporating specialized electronic components meaning that

due care is necessary to ensure trouble-free performance and avoid costly repairs.

To prolong the use of the device, observe the following precautions.

AVOID PROLONGED EXPOSURE TO EXTREME HEAT AND COLD Do not leave

the instrument in full sun or freezing temperatures when not in use.

Hardware

CLEGG HAMMER MANUAL

Page 8

CLE GG HAMMER.COM

KEEP CLEAN AND DRY Keep all components clean and dry, not only for correct

test operation but also for the sake of protecting the instrument. When testing, do not

allow material build-up inside the guide tube or on the hammer. Any build-up could

prevent an accurate free fall of the hammer. Ensure that the hammer strike face is

clear of any material build-up before starting each test. When transporting or storing

the instrument, wipe down the hammer and guide tube, etc., so that all is dry and

relatively clean. Never apply water under pressure when cleaning.

HAMMER AND CONTROL UNIT ARE NOT WATERPROOF Do not expose the

hammer or control unit to rain. If moisture enters either the hammer or control unit,

damage may result.

In conditions of extreme temperature, the control unit may not activate. If this is

suspected, allow the control unit to cool (or warm) before use.

CLEGG HAMMER MANUAL

Page 9

CLE GG HAMMER.COM

Clegg Impact Soil Tester with Clegg Control App

DO NOT EXCEED MAXIMUM LIMITS Overloading may cause permanent damage

to the accelerometer. To best protect theClegg, do not operate in such a manner

that values regularly exceed the device’s stated maximum limits. Maximum limits can

be found in the Specifications table on page 7 of this manual.

CLEGG HAMMER MANUAL

Page 10

CLE GG HAMMER.COM

Control: Power

If the hardness of the material to be tested is uncertain, start with drops from a very

low height, progressively getting higher until it is determined that it is safe to drop

from the standard drop height. If it is determined that the standard drop height is too

high, make note of what is considered to be a safe drop height for the particular

situation and develop criteria for such materials based on this lower drop height. Be

aware that this output is not directly proportional with the output obtained from using

the standard drop-height so any correlation with other outputs or test properties will

need to be re-determined or recalculated.

The accelerometer generates a signal regardless of any other electronics or power

supply; it is always “on” detecting vibrations. Protect the hammer from extreme

shock even when the Control Unit is not switched on or connected. Do NOT drop the

hammer directly on concrete.

EACH HAMMER AND CONTROL ARE CALIBRATED AS A SET Do not swap out

either the hammer or control unit. Mismatching of these parts will give inaccurate

results.

NEVER PLACE HANDS OR FEET IN OR UNDER THE GUIDE TUBE The hammer

is made to move freely inside the guide tube and injury is possible if hands or feet

are placed in the path of the hammer. Use special attention when lifting theClegg as

the hammer can slide.

WARNING: Only authorized personnel should perform disassembly and calibration.

Unauthorized disassembly or calibration will void any warranty.

To power on control unit, toggle the power switch to the ON position where

illuminated side of switch is depressed against the panel.

CLEGG HAMMER MANUAL

Page 11

CLE GG HAMMER.COM

Control: Hammer Connection

When control unit is powered on, the Power LED will flash to show the device is in

an unconnected state. At this time, the unit is able to be paired/connected to the

tablet. The control unit is paired via theClegg Control app (available Google Play or

Apple app store). When the device is in a connected state, the Power LED will stay

lit continuously.

If the device is left in an unconnected state for a period of 10 minutes, it will

automatically shut down. In order to power on the device on after an automatic

shutdown, do either of the following: • Plug the device in to charge • Toggle the

power switch OFF, then back ON

BATTERY The Control Unit contains a rechargeable battery. Recharge the battery

using the included charging cable. Do not replace the battery. A mismatch in battery

type can cause incorrect results or damage to the electronics and charger.

Unauthorized disassembly will void any warranty. Return the unit to Clegg Global for

battery replacement.

Control unit can be charged by either a computer ’s USB port or with the supplied

wall adapter. Charging via the supplied wall adapter results in a faster charge rate.

While unit is charging, the charge LED with be illuminated red. Once charging has

completed, the LED will shut off.

The cable is now internal and connects the hammer to the control unit.

CLEGG HAMMER MANUAL

Page 12

CLE GG HAMMER.COM

Control: Operational Check

A 2inch check cylinder is provided for the user to verify that the instrument is working

properly.

The operational check is carried out in a similar fashion as the standard test but

always with the check cylinder in place on a smooth concrete surface. The cylinder is

not used for normal testing but only when making an operational check.

Clegg Impact Soil Tester with Clegg Control App

CLEGG HAMMER MANUAL

Page 13

CLE GG HAMMER.COM

Operational Check Procedure

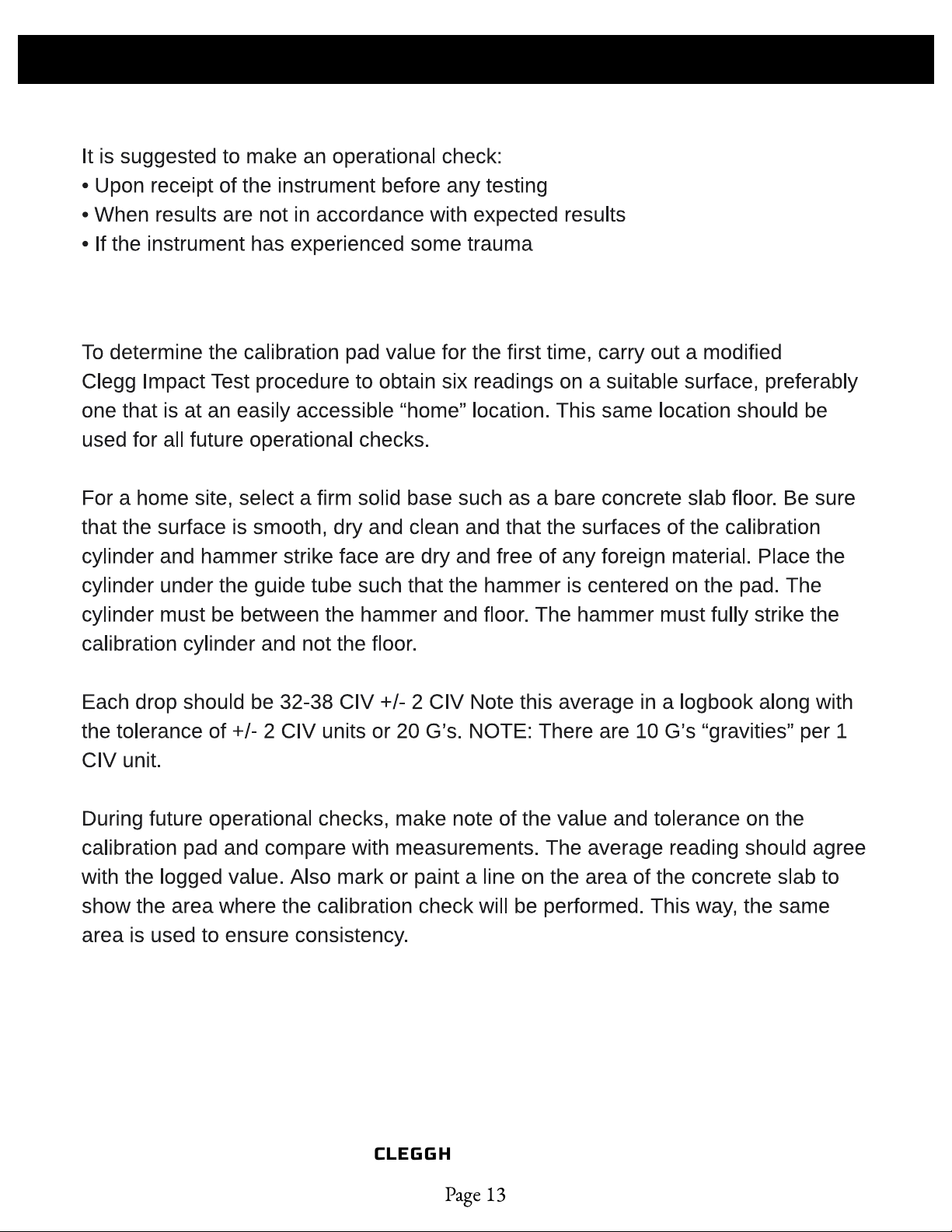

It is suggested to make an operational check:

• Upon receipt of the instrument before any testing

• When results are not in accordance with expected results

• If the instrument has experienced some trauma

To determine the calibration pad value for the first time, carry out a modified

CleggImpact Test procedure to obtain six readings on a suitable surface, preferably

one that is at an easily accessible “home” location. This same location should be

used for all future operational checks.

For a home site, select a firm solid base such as a bare concrete slab floor. Be sure

that the surface is smooth, dry and clean and that the surfaces of the calibration

cylinder and hammer strike face are dry and free of any foreign material. Place the

cylinder under the guide tube such that the hammer is centered on the pad. The

cylinder must be between the hammer and floor. The hammer must fully strike the

calibration cylinder and not the floor.

Each drop should be 32-38 CIV +/- 2 CIV Note this average in a logbook along with

the tolerance of + /- 2 CIV units or 20 G’s. NOTE: There are 10 G’s “gravities” per 1

CIV unit.

During future operational checks, make note of the value and tolerance on the

calibration pad and compare with measurements. The average reading should agree

with the logged value. Also mark or paint a line on the area of the concrete slab to

show the area where the calibration check will be performed. This way, the same

area is used to ensure consistency.

CLEGG HAMMER MANUAL

Page 14

CLE GG HAMMER.COM

Check Cylinder

Hammer Drop Procedure

The 4.5 kg model hammers may be dropped in the freehand method.

FREEHANDFor standard drop height, raise the hammer until the hammer hits the

stopper at the top, then drop. This stopper ensures the proper drop height is

achieved each time.

CAUTION: Do not operate hammer on concrete without the calibration cylinder in

place as damage to the instrument may result.

CLEGG HAMMER MANUAL

Page 15

CLE GG HAMMER.COM

The suggested standard protocol for performing a Clegg Impact Value (CIV) for

surfaces where Compaction Control is the goal is the original four-drop peak protocol

developed by Dr. Clegg. Compaction Control is used for surfaces that are being

prepared for roads, bridges, foundations, or trench reinstatement.

Typically, the 4.5 kg or 10 kg hammer models are used for Compaction Control.

Compaction Control

Performing a Clegg Impact Test

Outlined below are typical test protocols for Compaction Control and Impact Control.

The Compaction Control protocol is employed to measure highly compacted

materials potentially used in a construction site. The Impact Control protocol is used

to measure materials where high compaction is undesirable such as athletic fields.

Testing protocols may vary depending on the material and parameters being

evaluated.

Set up appropriate Compaction Control test parameters in Clegg Control app.

See

the Test Setup section on page 24 for more detailed app setup instructions.

Impact Control

The suggested protocol for performing a Clegg Impact Value (CIV) for surfaces

whereImpact Control is the goal is a one-drop protocol. Impact Control is used in

situations where soft surfaces and hard surfaces could result in the decline of

performance and the increase in injuries (athletic fields, racetracks, tennis courts,

golf courses, etc.).

CLEGG HAMMER MANUAL

Page 16

CLE GG HAMMER.COM

Typically the 0.5 kg and 2.25 kg hammer models are used for Impact Control.

Additionally, impact values noted in literature for natural and synthetic turf are often

displayed in gravities (G’s). NOTE: There are 10 G’s “gravities” per 1 CIV unit.

Set up appropriate Impact Control test parameters in Clegg Control app. See the

Drop Modes section on page 20 for more detailed app setup instructions. 10

These surfaces are exposed to routine maintenance such as tilling, grating, aeration,

and leveling steps with the intent of producing a finished product which falls within a

specific range or window of impact values (not too soft and not too hard).

Custom Protocols

Based on an examination of literature, different protocols have been used to target

different surface and subsurface characteristics. These custom protocols (different

number of drops, variations in drop height, peak impact value, or average impact

value) can be effective when consistently used across an area.

In the case of Impact Control, there are no hard and fast rules because the results

are dependent on soil type, organic matter, moisture content, and the influence of the

turf grass and its root zone. It is recommended to run a few experiments to

determine the protocol that works best for your application or use your experience

which may well be the best predictor of what range of impact values provide the

desired results.

To determine a custom protocol, the initial step would be to collect or use historical

data (Clegg impact values) on surfaces you want to monitor. Take experimental data

when the surface is in a desired condition and an unacceptable condition.

CLEGG HAMMER MANUAL

Page 17

CLE GG HAMMER.COM

With this data you can:

• Select an acceptable range of impact values for the surface

• Track the change in impact values as maintenance or modifications are made to

the surface

NOTE: Field test data has shown strong correlations between Clegg Impact Values

or gravities (G’s) to a number of other units of measure for Impact and Compaction.

The F355 formula is with a 2.25 kg and the MPa and CBR formulas are taken with a

4.5 kg.

• F355 (Clegg g’s+ 27.1) /.81

• MPa 0.088 (CIV)^2

• CBR .1691 (CIV)^1.695

Clegg Impact Soil Tester with Clegg Control App

CLEGG HAMMER MANUAL

Page 18

CLE GG HAMMER.COM

Testing Procedure

Once the desired protocol has been chosen and set up in the Clegg Control app,

follow this procedure to complete the testing process.

1. For standard Compaction and Impact Control tests, be sure that Display: PEAK is

selected in the Clegg Control app settings.

2. Enter or select the appropriate drop site in the Clegg Control app. For more

information about setting a drop site, read the Drop site on page 27.

3. Ensure that the app is open and a new location is set ready to receive a value.For

more information, read Control: Hammer Connection on page 10.

4. Ensure that the striking face of the hammer is free of foreign material and the

inside of the guide tube is reasonably clean so that the hammer is able to fall freely.

5. Locate then select the appropriate drop location in the Clegg Control app and

clear any loose surface material or foreign objects from the test spot that could

produce a result not indicative of the material being tested. Scuffing with a foot is

generally adequate.

6. Place device vertically in position and hold down guide tube with a foot on the

base flange. Brace guide tube with leg and/or knee (if necessary) to hold tube steady

and as close to vertical as possible.

7. For Compaction Control Raise the hammer to white line and drop. Without moving

the guide tube, repeat this step three more times for a total of four drops and save

the readings into memory. This set of four drops represents the standard compaction

test protocol.

8. Move to next drop location and repeat steps 3 through 7.

Depending on the surfaces/materials being tested, a custom protocol may be

used.For Impact Control Raise the hammer to the stopper at the top and drop. This

single drop represents the standard impact test protocol.

CLEGG HAMMER MANUAL

Page 19

CLE GG HAMMER.COM

Raise the hammer until the hammer hits the stopper at the top of the guide and

release.

Standard Drop Height

Plunger* to release the hammer to drop. 96055 10 kg

ASTM and Australian Standards

ASTM D5874 Standard test method for determination of the impact value (IV) of a

soil.

AS 1289.6.9.1 Soil strength and consolidation test – Determination of stiffness of soil

– Clegg impact value (CIV).

Hardware Warranty

Clegg Global guarantees its instrumentation against all defects in materials and

workmanship to the ORIGINAL PURCHASER for a period of one (1) year from the

date of shipment, unless otherwise stated. During this period, Clegg Global will

repair or replace, at its option, any instrumentation found to be defective in materials

or workmanship. If a problem arises, contact our office for prior authorization before

returning the item. This warranty does not extend to damaged instrumentation

resulting from alteration, misuse, negligence or abuse, normal wear or accident. In

no event shallClegg Globalbe liable for incidental or consequential damages.

Table of contents