6

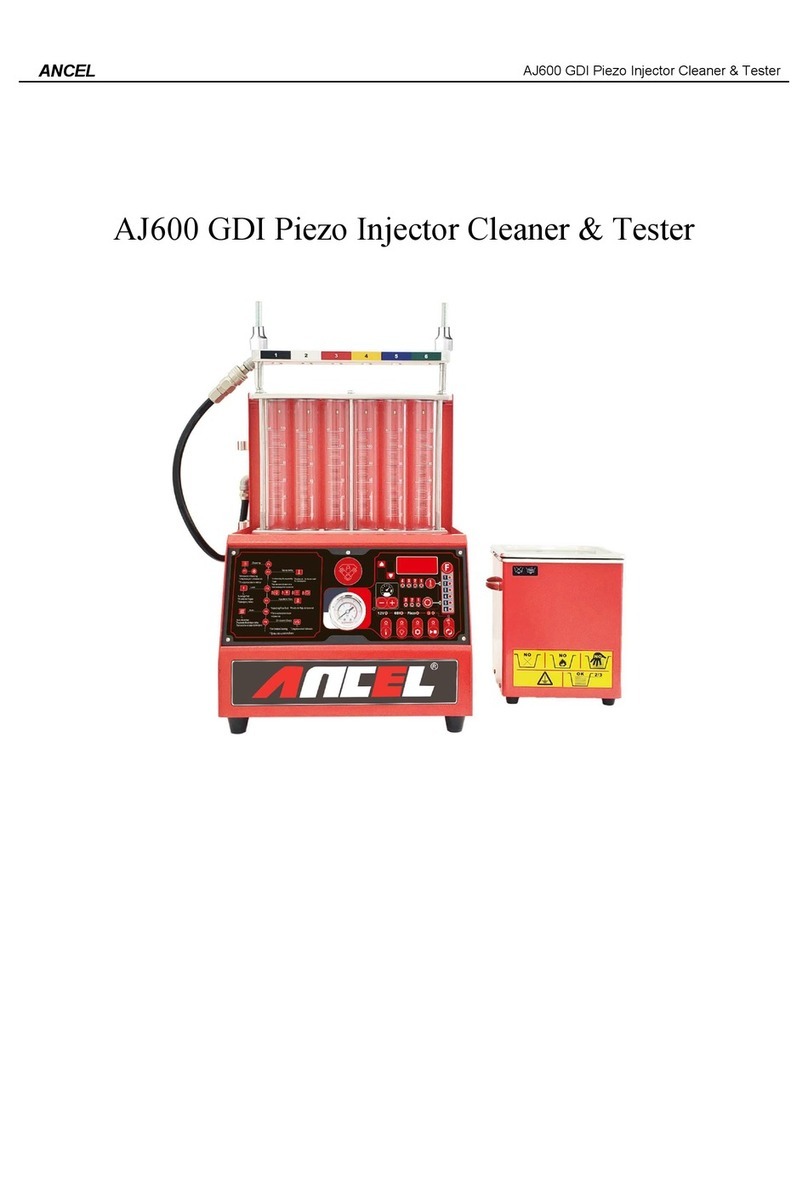

AJ400 GDI

Injector Cleaner & Tester

ANCEL

V. Operation

Important reminder: Before any operation, choose the correct injector type for proper operating. Press the GDI key

with the indicator light ON for GDI injectors. For general top-feed or side-feed injectors, no need to press this

key.

5.1 esistance Test

1) Connect one end of the resistance measurement line to the interface on the right side of the device, and the other

end to the two electrodes of the fuel injector.

2) Start the machine, and press the key. The resistance value will e displayed on the screen.

3) If needed, measure several times to confirm the measured value.

4) After the measurement is completed, remove the fuel injector and the resistance measurement line.

5.2 Ultrasonic Cleaning

Injector Cleaner takes advantage of the penetra ility and cavitation impact wave caused y ultrasonic wave traveling

through the medium to provide powerful cleaning on o jects with complex shapes, cavities and pores, so that the

stu orn car on deposits can e removed from the injectors.

Procedures

1) Place the injector/pump which has gone through surface cleaning in the launder.

2) Add enough injector detergent into ultrasonic cleaner so that the liquid level is a out 20mm a ove the needle

valve of injectors / whole pump.

3) Plug the pulse signal wire to injector / pump respectively.

4) Select ultrasonic cleaning function and then set the time.

5) Press

RUN

key to start the procedure.

6) Turn on the ultrasonic cleaning switch on the left side of the machine.

7) When the time is up, it will stop automatically as the eeper rings.

8) Turn off the ultrasonic cleaning switch on the left side of the machine after cleaning procedure.

9) Take the injector / pump out of the launder and wipe them with a dry soft cloth. Get ready for next operation.

Note:

1) It is strictly for idden to open the ultrasonic system under the circumstances that cleaning agent has not een added

into the ultrasonic cleaning pool. Otherwise, the ultrasonic equipment may e damaged easily.

2) It is strictly prohi ited to immerse the pulse signal line connector along with the injector into the ultrasonic pool

for cleaning. Otherwise, the pulse signal line connector can e damaged easily.

3) ATTENTION: Make sure to turn off the ultrasonic cleaning switch on the left side of the machine after cleaning

procedure.

5.3 Uniformity/Sprayability Test

Uniformity test is to find out the difference of the injectors injecting at the same working condition. This test can

indicate the comprehensive influences on the injector caused y electrical nature, ore variation and clogging. Spray

a ility test is to inspect the spraying performance y o serving the injectors.

Installing and testing procedures for injectors

1) Choose a proper adaptor according to the injector type and mount it to the fuel separator.

2) Install the injectors in forward direction (Apply a little lu ricating grease on the O-ring.)

3) Install the fuel separator with injector onto the plate of the test tu e.

4) Connect the injector pulse signal wire.

5) Before doing this test, drain the test liquid from the measuring cup if there is any.

6) Select Uniformity/Spraya ility test function, set corresponding parameters (consult the appendix for pressure

setting, consult vehicle manuals for other parameters as needed), and then press RUN key to start the test.

7) When the test is completed, the equipment will auto stop with the ring of the uzzer.

Note:

1) The system pressure can e adjusted y pressing + or – at testing.