Anchor VMS 25x32 User manual

Other Anchor Tent manuals

Anchor

Anchor Venue Series User manual

Anchor

Anchor Navi-Trac User manual

Anchor

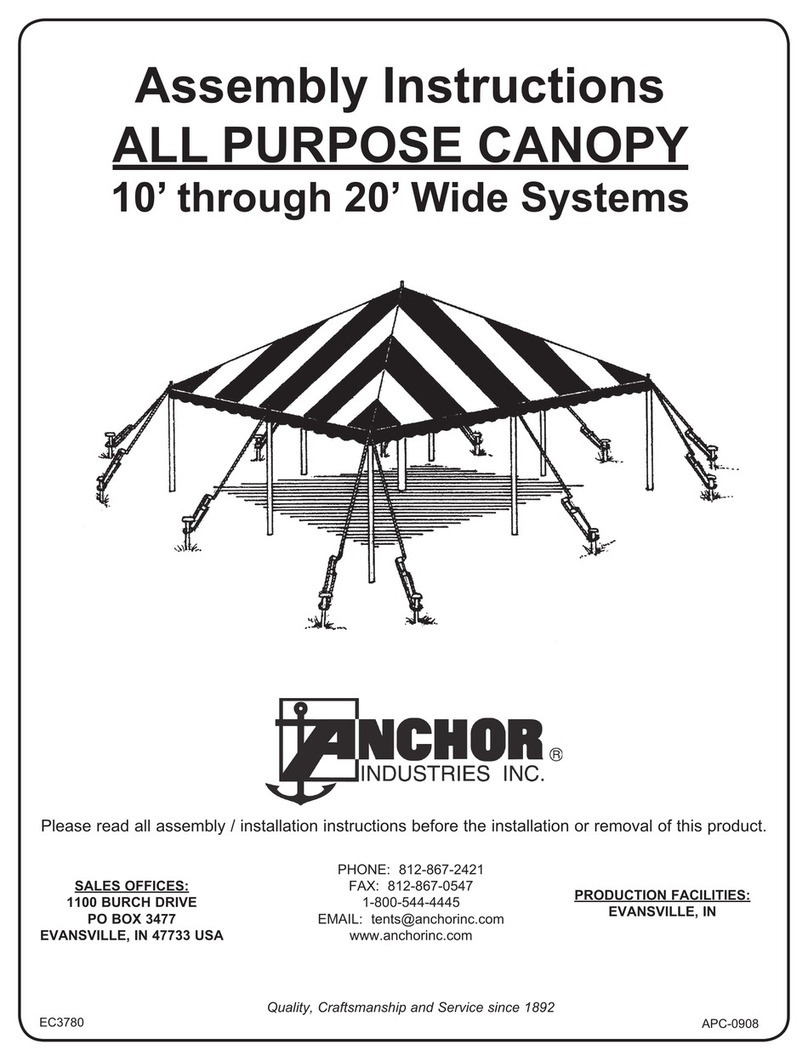

Anchor 10’ User manual

Anchor

Anchor ETI 30’CLASSIC FRAME TENTS User manual

Anchor

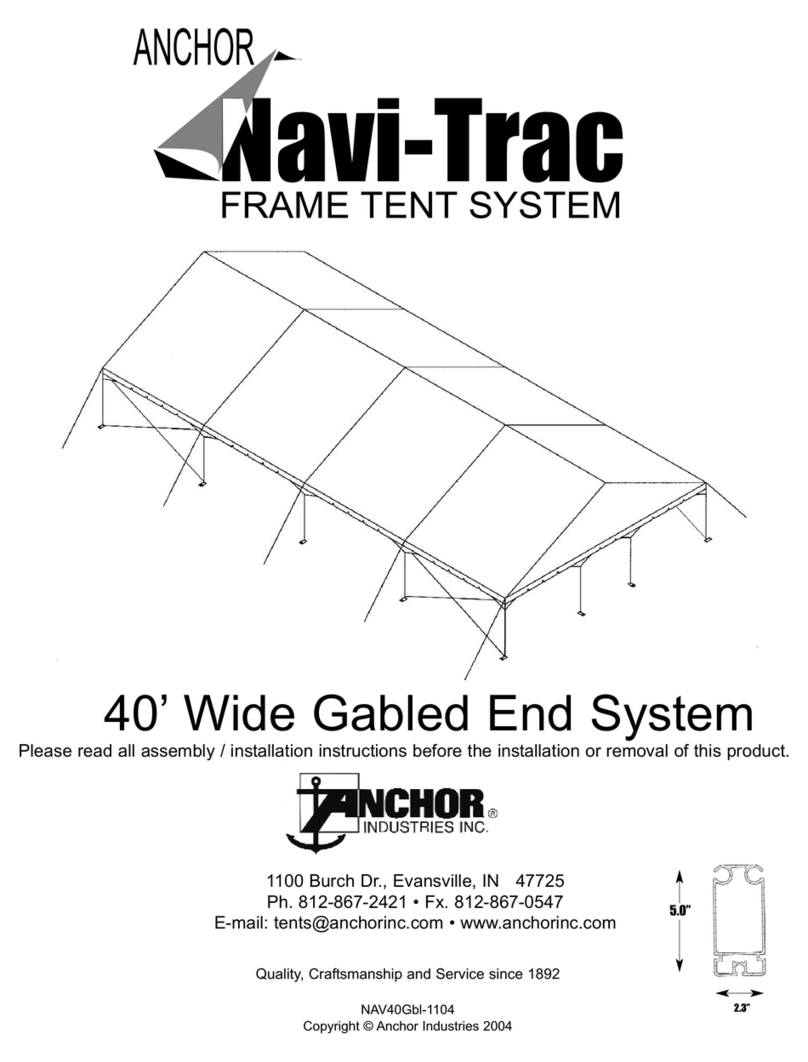

Anchor NAVI-TRAC NAV40GBL-1104 User manual

Anchor

Anchor Economy Tent International XP Series User manual

Anchor

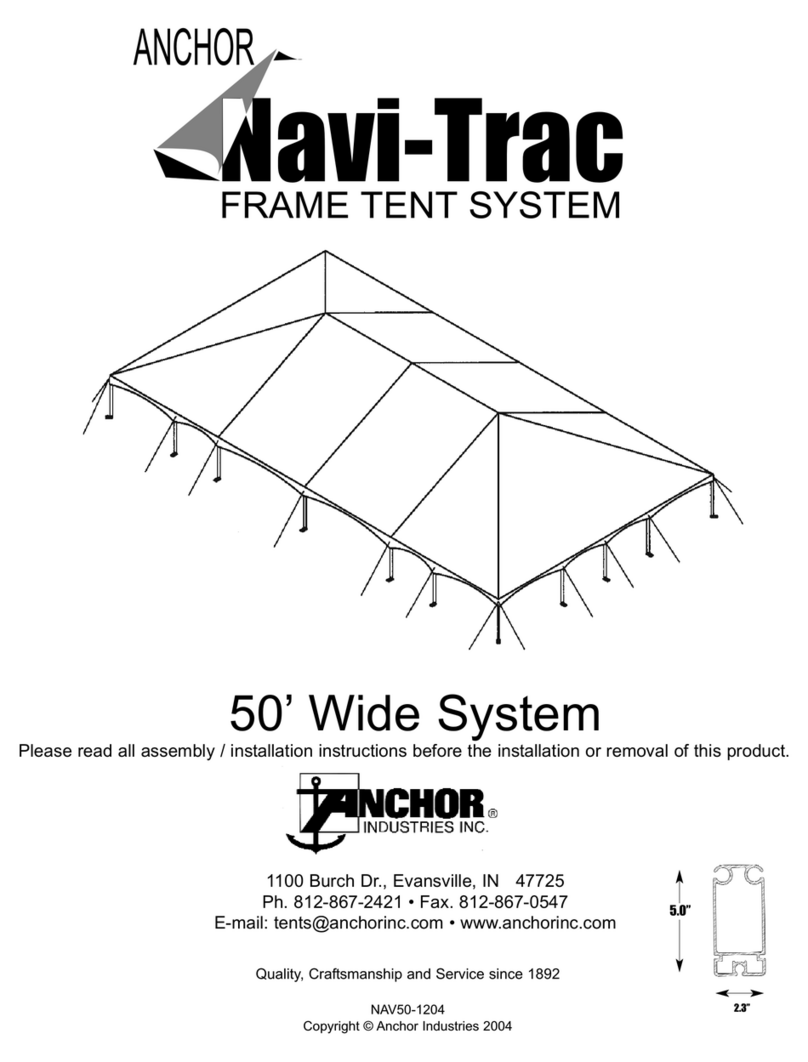

Anchor NAV50-1204 User manual

Anchor

Anchor Venue Series User manual

Anchor

Anchor Fiesta User manual

Anchor

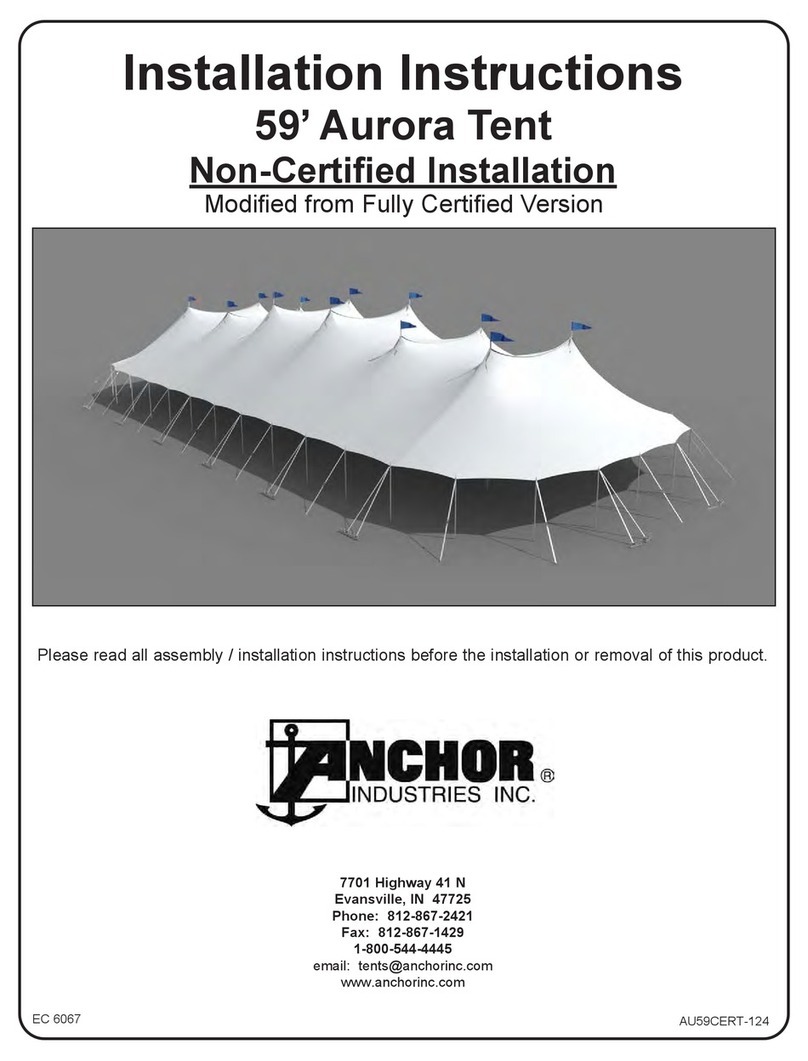

Anchor 59 Aurora User manual

Anchor

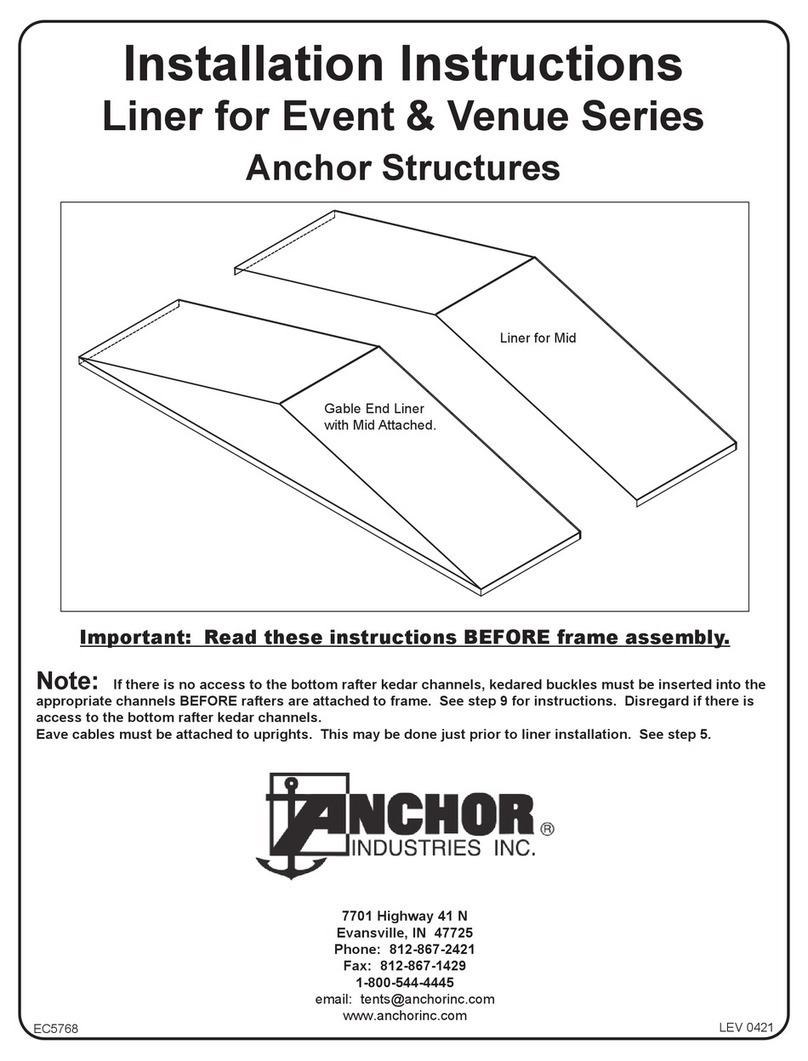

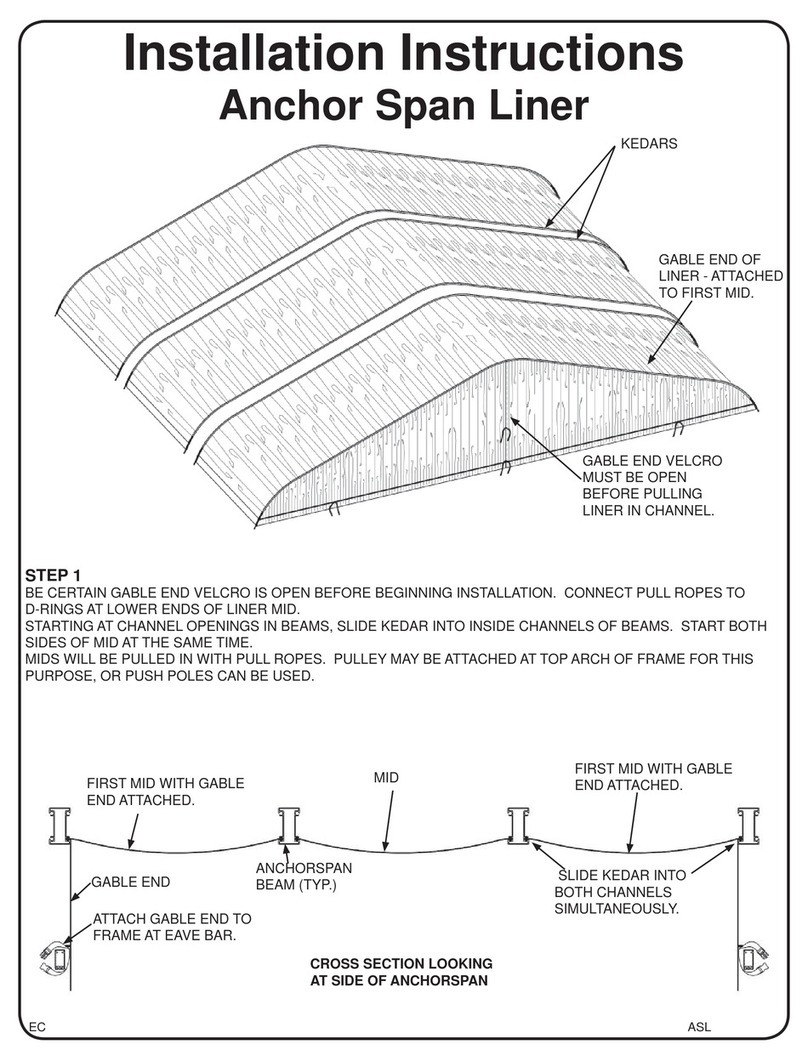

Anchor AnchorSpan Liner User manual

Anchor

Anchor Aurora 51 User manual

Anchor

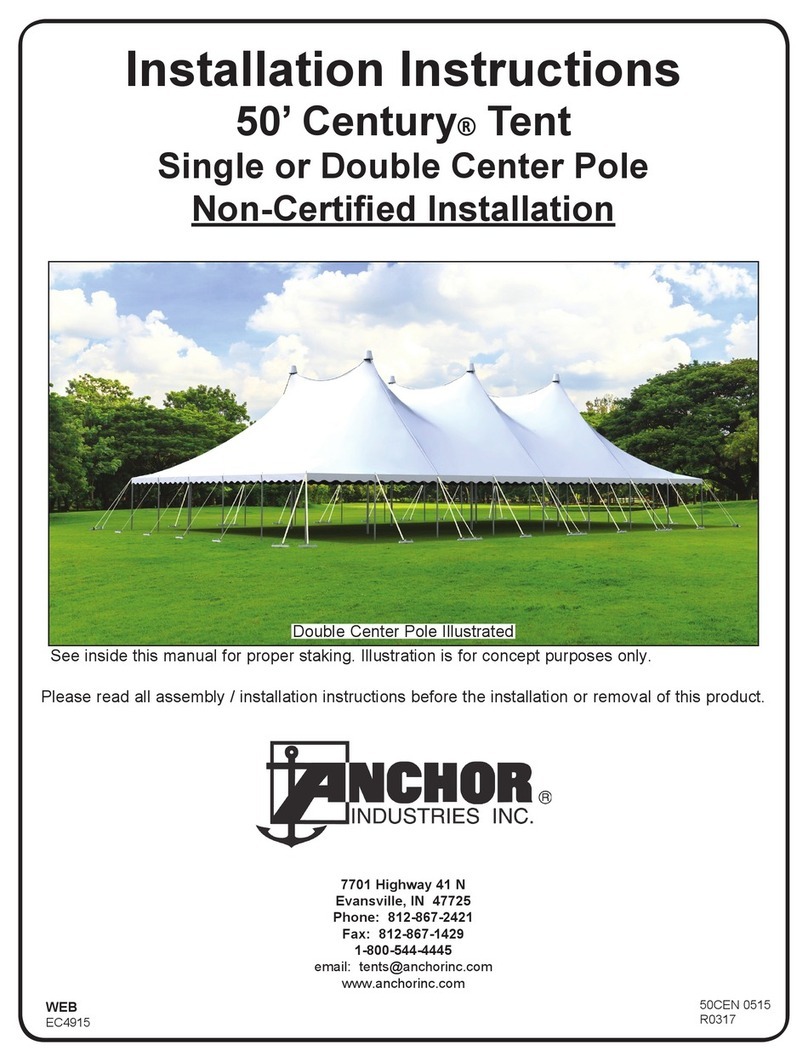

Anchor Century User manual

Anchor

Anchor 32 Aurora User manual

Anchor

Anchor 32 Aurora User manual

Anchor

Anchor Event Series User manual

Anchor

Anchor Fiesta User manual

Anchor

Anchor 45' Aurora Tent User manual

Anchor

Anchor F3 User manual

Anchor

Anchor Navi-Trac Lite User manual

Popular Tent manuals by other brands

Coleman

Coleman 2000033134 Assembly & instruction manual

Ozark Trail

Ozark Trail W784.1 Assembly instructions and owner's manual

SlingFin

SlingFin CrossBow 2 instructions

Coleman

Coleman 9600-141 instructions

Palram

Palram Arizona 5000 Wave - WINGS manual

COVERPRO

COVERPRO 56184 Owner's manual & safety instructions