SERVICE INSTRUCTION

Tools required for service:

Screwdriver (large).

Screwdriver (small).

Winch handle.

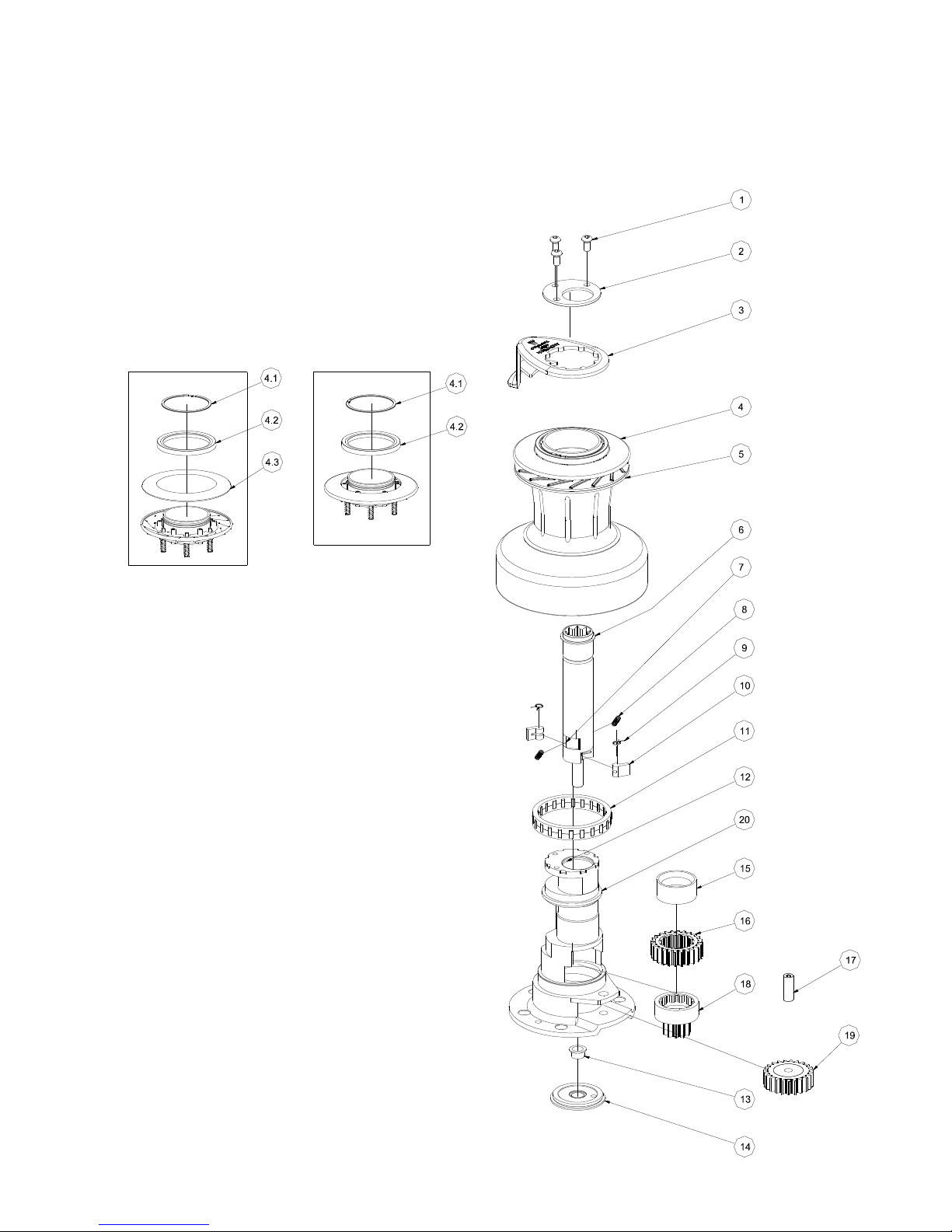

1. Remove screw (1) and top cap (2).

2. Remove self-tailing arm (3) and drum (5).

3. Insert a winch handle. Pull up the drive shaft (6) gently while turning gear wheel (19) and

ratchet gear (16) carefully. Remove drive shaft (6).

4. Remove lower pawls (10) arm springs (9) and springs (8). The upper pawls are not

removable.

5. Remove ratchet gear (16) and bushing (15).

6. Remove ratchet gear (18).

7. To release the roller bearing (11) gently insert a small screwdriver between roller bearing

and base (20). Remove roller bearing (11).

8. Remove shaft (17) and gear wheel (19). Use a screwdriver.

9. Clean all parts in petrol. Remember to clean the gear teeth.

10. Assemble in reverse order. During assemble lightly grease all gear teeth drive shaft roller

bearing shafts pawls springs and bushings. Use a small soft brush. Pawls may be

lubricated with either a very thin film of ANDERSEN WINCH GREASE. It is very important

that pawls can move freely.

IMPORTANT: When assembling the winch check the functioning of each pawl by pushing the

pawl against the spring. The pawls should move smoothly and automatically return to their normal

position where the pawls engage with the teeth. If the pawls do not function correctly clean and

lubricate the pawls and gears. Check the function of the pawls again to make sure that it works

correctly. If the pawls do not work correctly replace the springs and recheck the functioning.

Not properly functioning pawls may lead to unexpected release of the winch force resulting in fatal

injuries to the user and others.

Service Kit No: 1 (art. no. 710018) contains spare parts for this winch.