10 Remove feeder screw when ex-

trusion is almost all the way on.

3 Snap on the lower spacer tube,

using pliers if necessary,and cut

it to length as shown .

11 Remove feeder by sliding it

downward.

14

Tape full length of lower spacer

tube with tape provided.

.

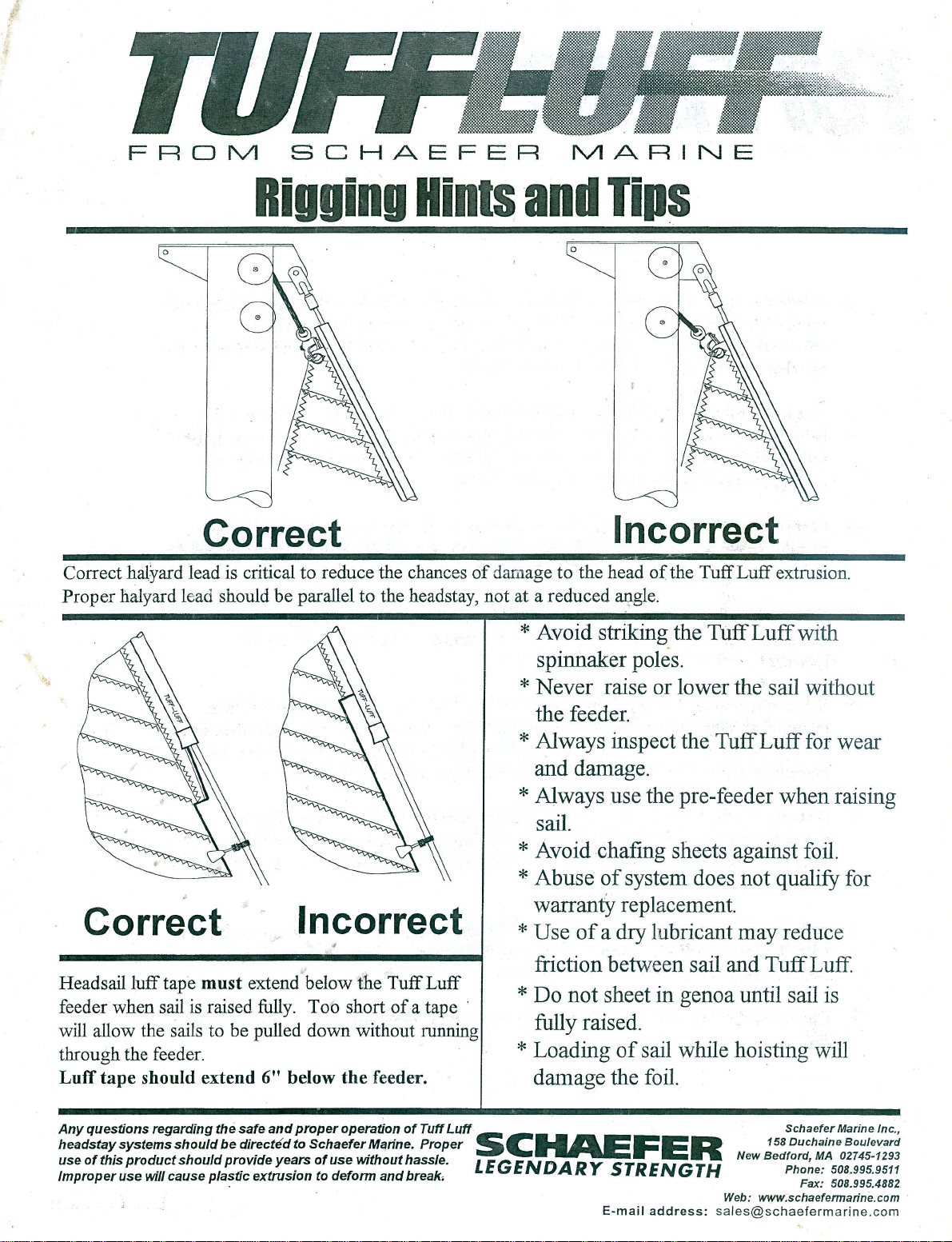

16 T,ape seizing line with the tape 17With sail raised, luff tape should

provided.protrude 6" below feeder.

/

ASSEMBLY TIME:Approximately 14 minutes.

METHOD B:

Installing extrusion with mast stepped without measuring

forestay:

Step 1:Snap on 4" top spacer tube and tape as shown in

Steps 6 and 7,Method A.

Step 2: Slide extrusiononto headstay UPSIDE DOWN (with

feeder removed).

Step 3: Cut off 42" above deck.

Step 4: Pull extrusion off headstay and slide on ag~i,nright

side up. .

f.

Step 5: Proceed with Step 12 from Method A.,

'ii·

12Finish snapping extrusion on

and replace feeder, taking care

to"catch"the port groove behind

ridge inside feeder. Screw

should be just flush with port

side of feeder when installed.

DO NOT OVERTIGHTEN.

15 Seize roller prefeeder 12" below

feeder.

Sail with it When raising sails,

always use both feeder and roller

prefeeder to prevent chafe.

METHODC:

Installing with mast unstepped: Stretch headstay

very

taut at

a good working height (waist level) and proceed as with

Method A or B.

SCH EFER

IIIIAR NE

I-

158 Duchaine Blvd., Indus-trial Park

.New Bedford, MA 02745-1293

Phone:508-995-9511 Fax: 508-995-4882

E-mail address:sales@schaefermarine.com

i