- 1 -

I. INTRODUCTION TO THE GYROTORK ................................................................................ 3

DEFINITIONS: .................................................................................................................... 3

•Internal Channel or V1: Torque transducer wrench........................................................ 3

•External Channel or V2 or SPIP: Angle sensor ............................................................... 3

II. HANDLING.................................................................................................................... 4

1. Unpacking................................................................................................................. 4

2. Recommendation before first use................................................................................ 4

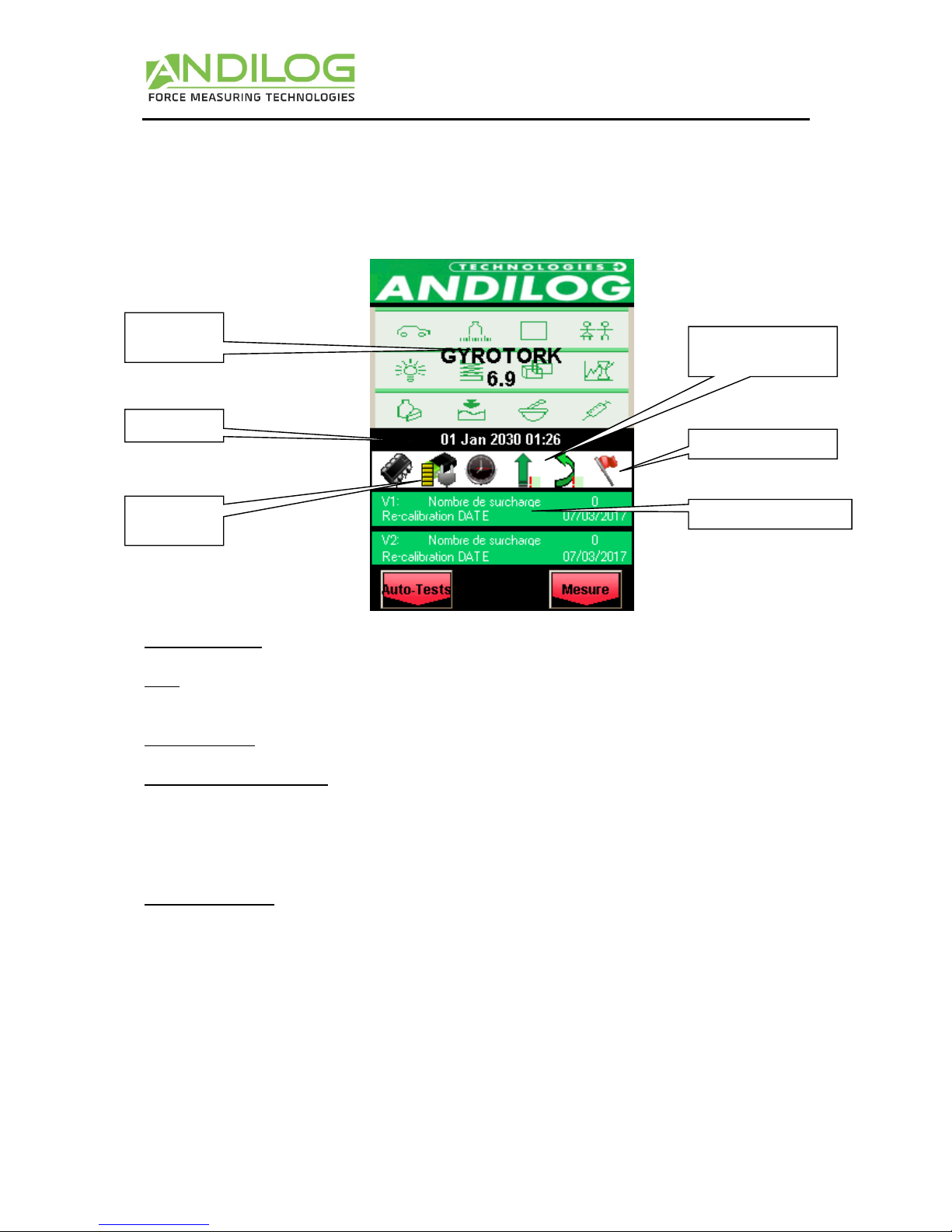

3. Starting your torque gauge ......................................................................................... 5

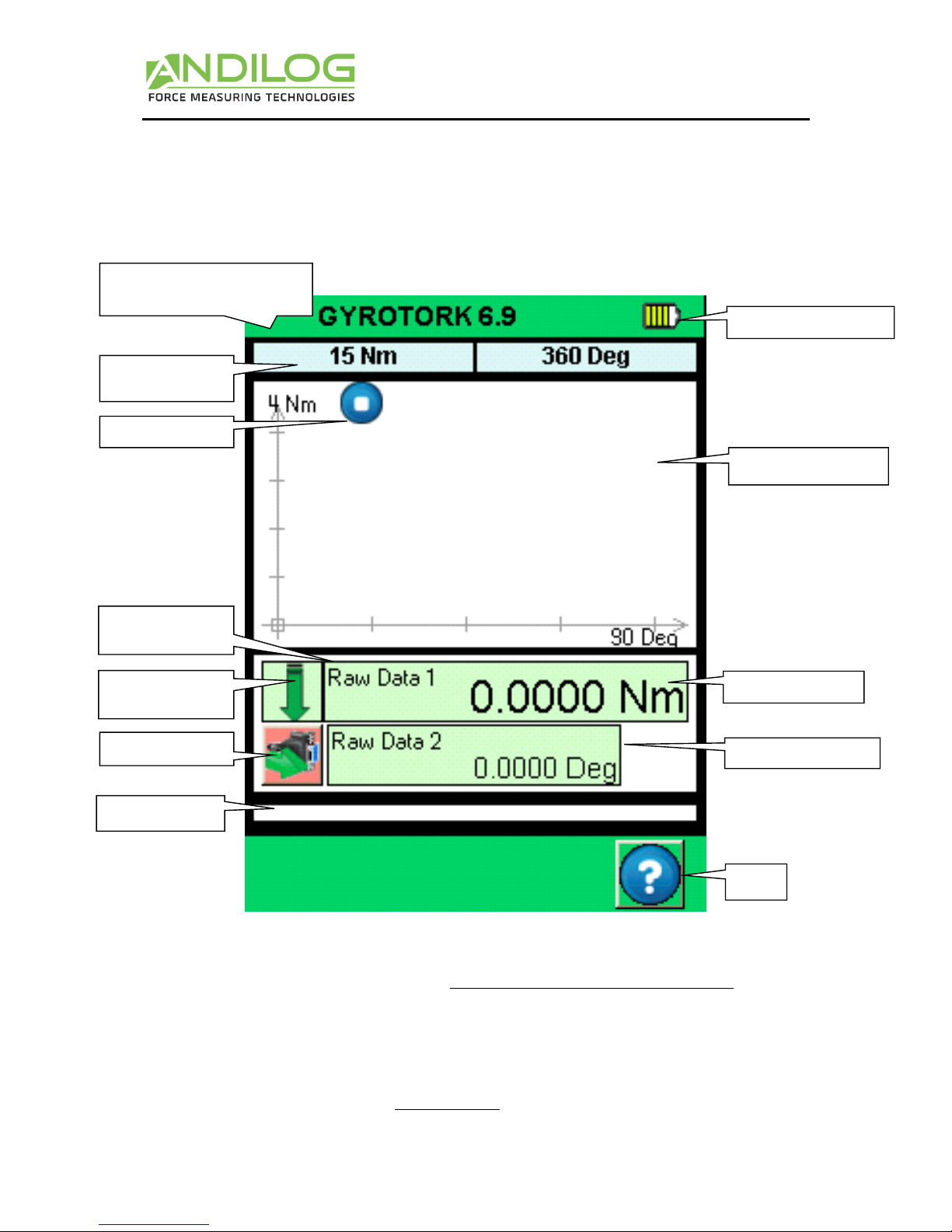

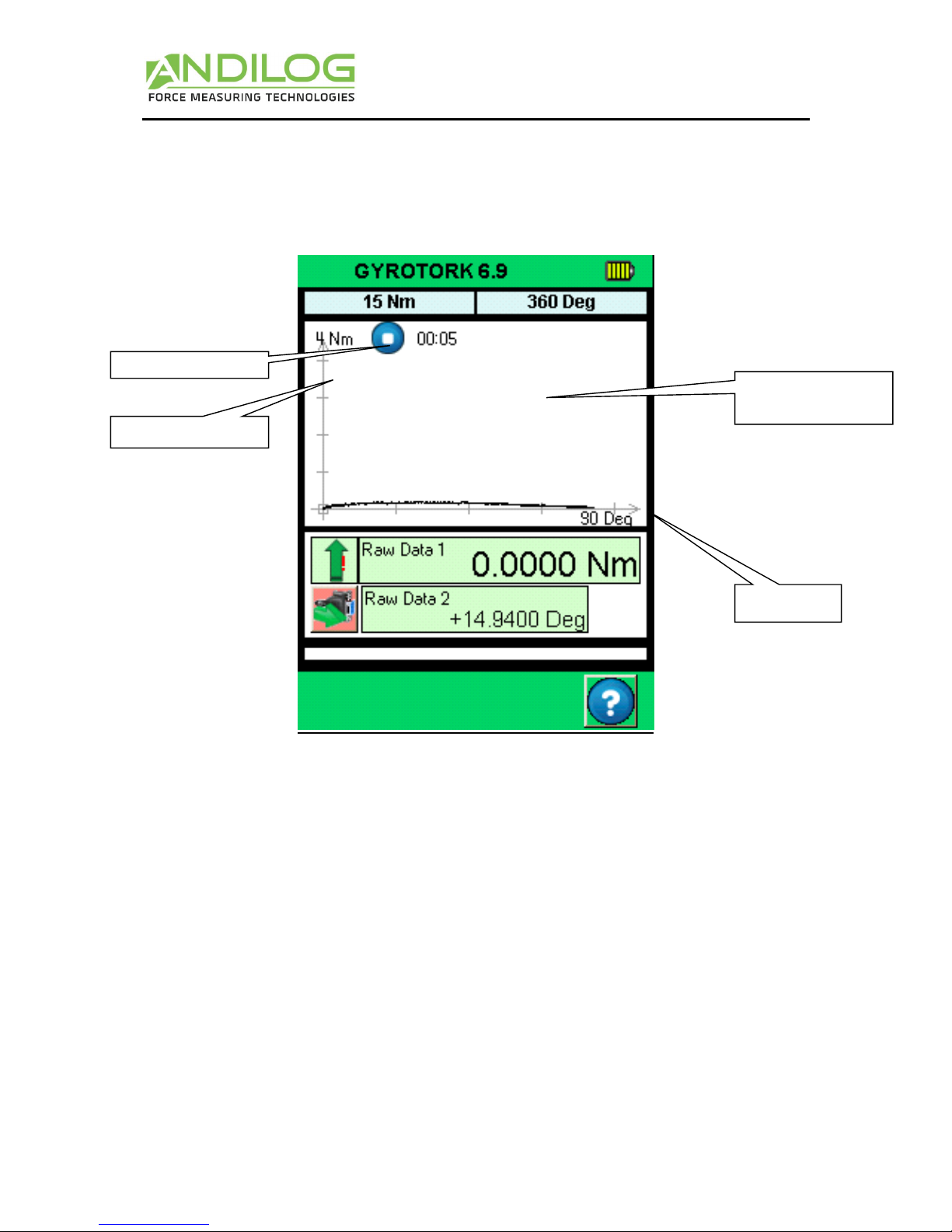

4. Main screen –Measurement ...................................................................................... 6

5. Touch area on the Measure screen.............................................................................. 7

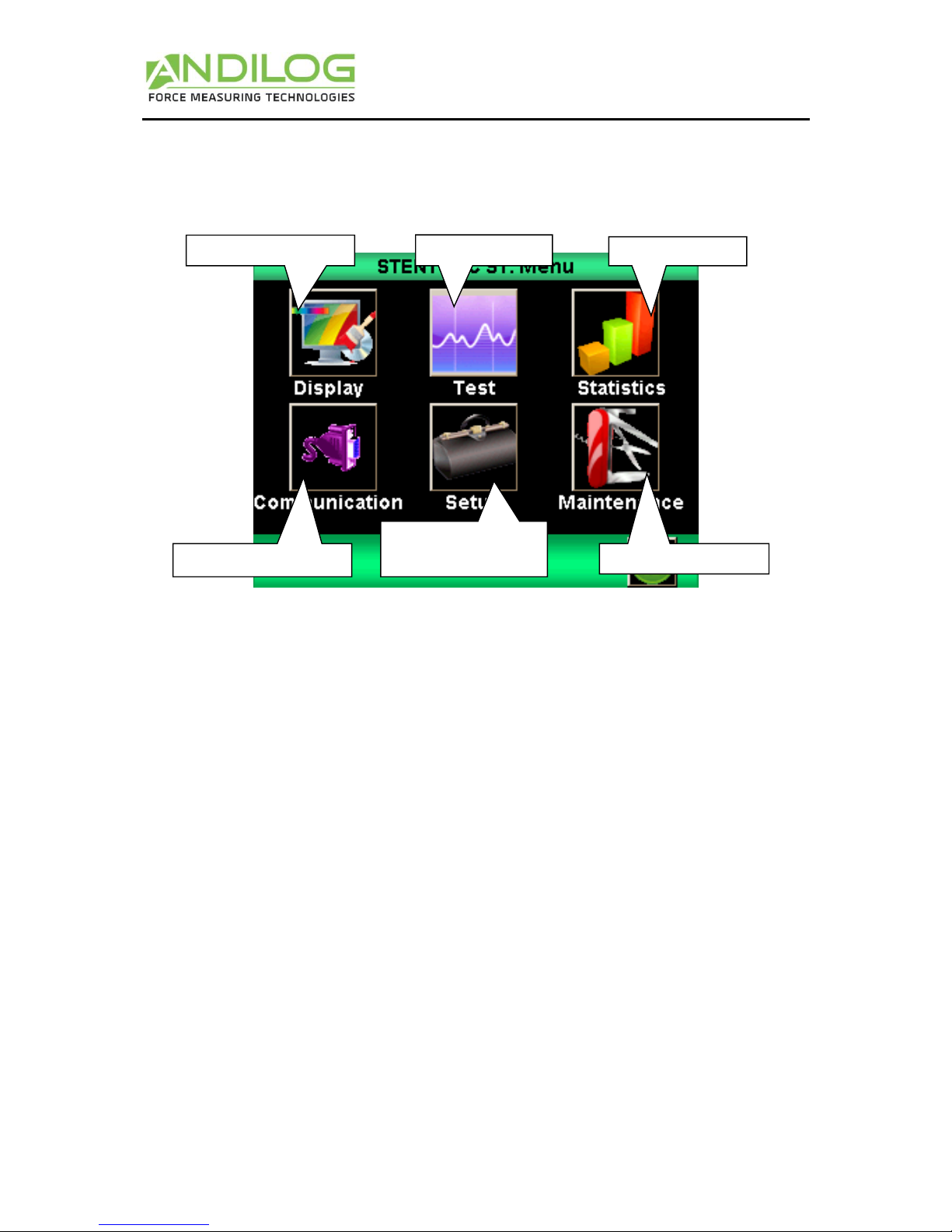

6. Main MENU .............................................................................................................. 8

7. Tare your device:....................................................................................................... 8

8. Backlight................................................................................................................... 8

III. START your measurements............................................................................................. 9

1. Measurement principles............................................................................................10

2. States Indicators.......................................................................................................10

3. Graph displaying area................................................................................................10

IV. DISPLAY setup..............................................................................................................11

1. Main screen .............................................................................................................12

2. Auxiliary ..................................................................................................................12

3. Curve ......................................................................................................................12

4. Bar Graph ................................................................................................................12

5. State .......................................................................................................................12

6. Digits.......................................................................................................................12

7. Time unit .................................................................................................................12

8. Sensor Units V1 ........................................................................................................13

9. Set points - Limits .....................................................................................................13

V. SET POINTS Setting - Limits............................................................................................13

1. Activate/Deactivate ..................................................................................................13

2. Torque transducer tab...............................................................................................13

3. Type of Data ............................................................................................................14

4. Top and Bottom limits...............................................................................................14

5. Activate an Output....................................................................................................14

VI. GRAPH & TEST Settings. ................................................................................................15

1. Setups tab................................................................................................................15

2. Test settings.............................................................................................................15

3. Curve Resolution ......................................................................................................16

4. Axis H & Axis V .........................................................................................................16

5. Output control .........................................................................................................16

VII. CALCULATION Settings ..............................................................................................17

1. Calculation...............................................................................................................17

2. Output actions .........................................................................................................18

VIII. RECORD DATA AND STATISTICAL Mode. ......................................................................18

1. Statistics setup .........................................................................................................18

2. Record data .............................................................................................................19

IX. COMMUNICATION Settings. ..........................................................................................20

1. RS232 or Serial commands.........................................................................................20

2. USB Connection........................................................................................................22

3. Bluetooth (Optional) .................................................................................................22

4. Analogue Connection................................................................................................22