Page 2

Power supply ..................................................................................... 230/240 VAC 50/60 Hz +/- 10%

Power consumption ......................................................................................................................3,1 W

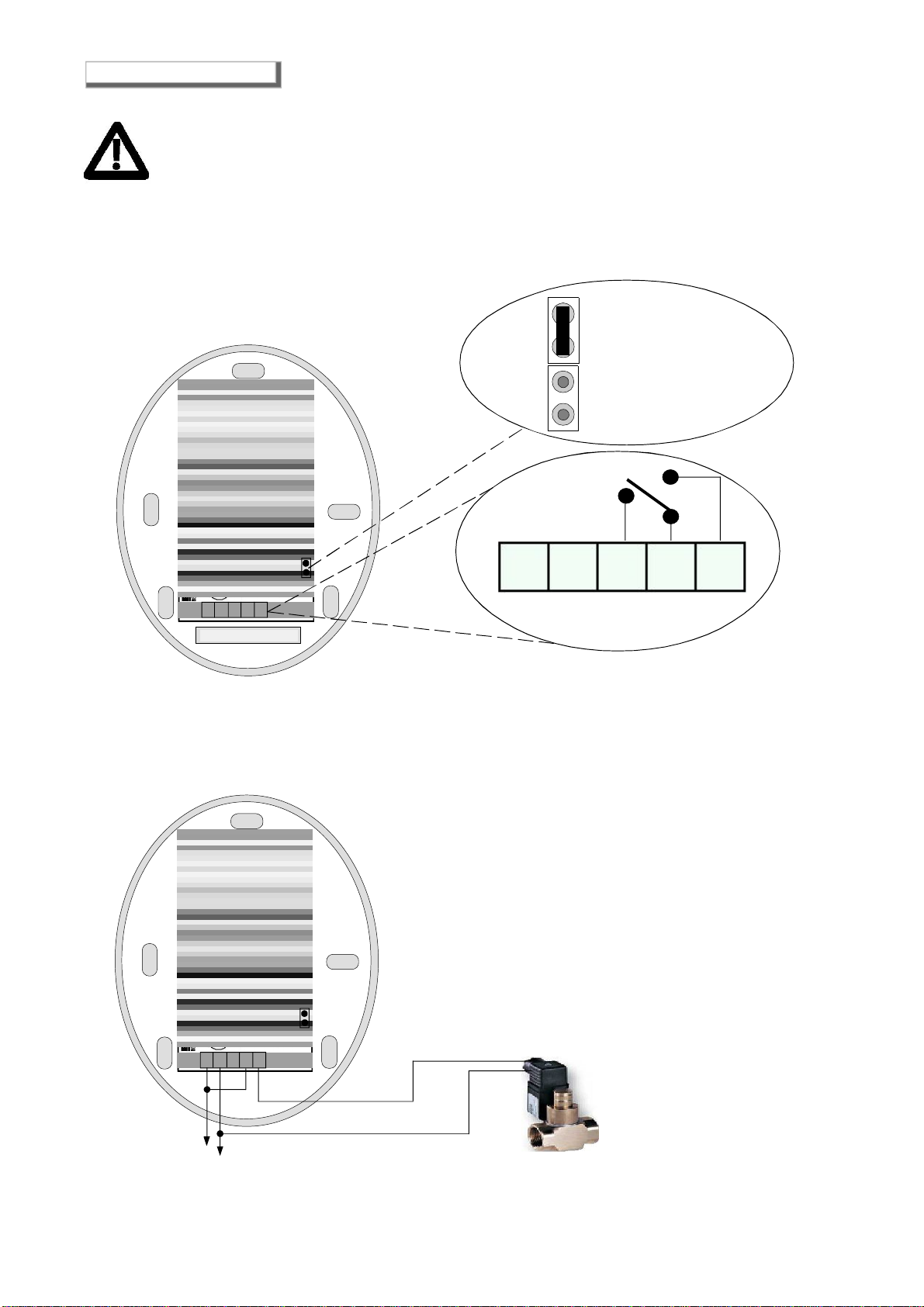

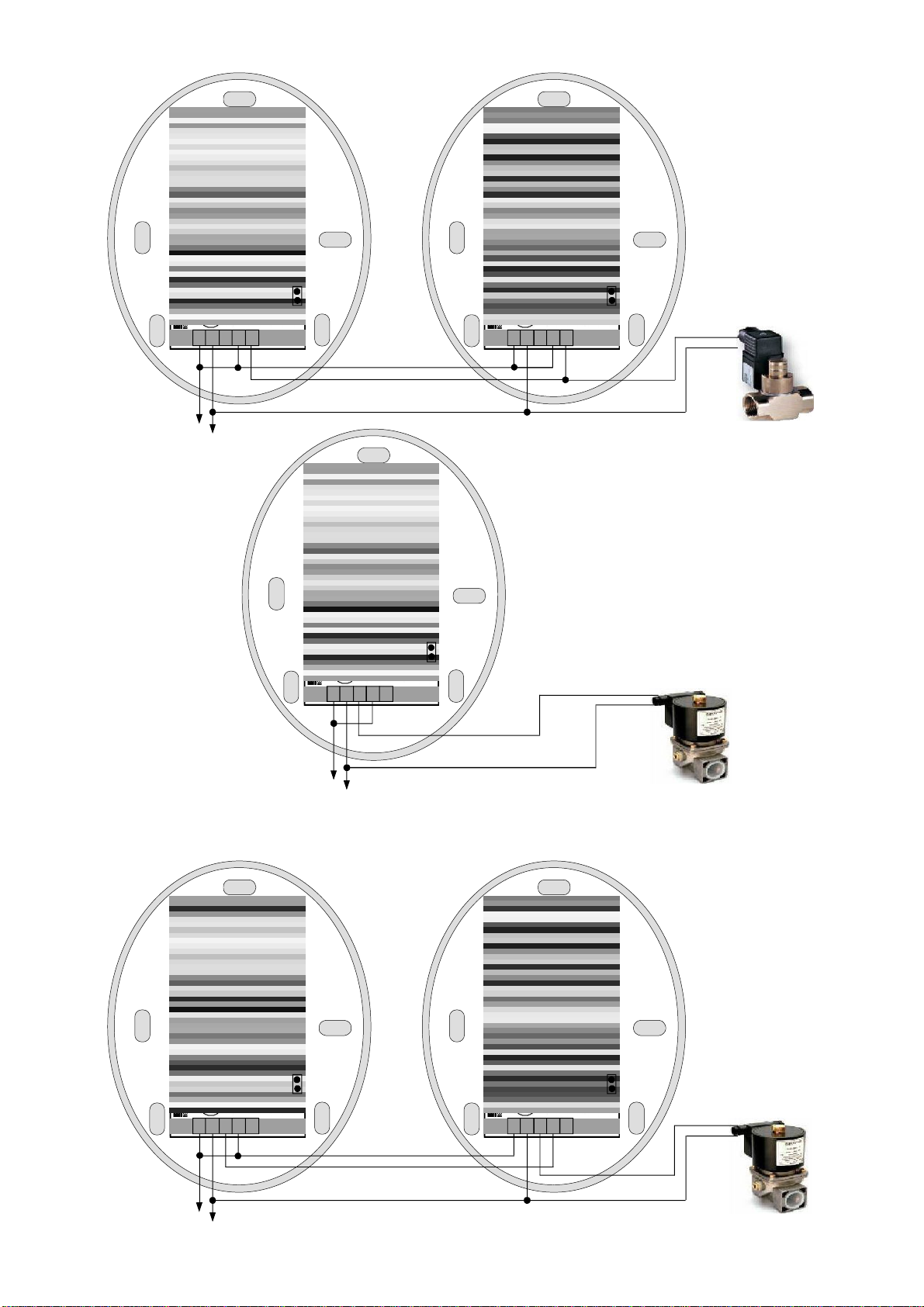

Range of relay contact switching free of voltage ............................................................. 10A 250V resistive

Insulation ........................................................................................................................... Class II

Types of gas detected ................................................................................. Natural Gas - for Natural gas

LPG- for LPG model

Detection sensor ....................................................................................................................... Catalytic

Alarm sensitivity ......................................................................................................... At 10% of L.E.L.

Precision of the detector ............................................................................................................. 1% FS

Sensor’s faults detected by Fault Circuit ................................................... Interruption, short circuit, or wear

Test Phase Duration ............................................................................................................. 60 seconds

Audible and visual signal alarm by ............................................................. LED diode and buzzer 85 dB at 1 m

Selection of relay working mode ........................................................................................ through Jumper

Test buttons ........................................................................................................................... built-in

Command electrovalve ................................................................................................ class A o classe B

Functioning Temperature ............................................................................................... -10°C to +40°C

Functioning Humidity ......................................................................................... 0÷90% RH not condensed

Degree of protection ...................................................................................................................... IP42

Dimensions ....................................................................................................................... 115x150x50

CHECK the integrity of the probe after having removed it from the box.

Check that the data written on the box correspond to the type of gas used.

When doing the electrical connections, follow the drawing closely.

Any use of the detector for purposes other than the intended one is considered improper, and as a result of

which BEINAT S.r.l. therefore disclaims any responsibility for possible damages caused to people, animals

or objects.

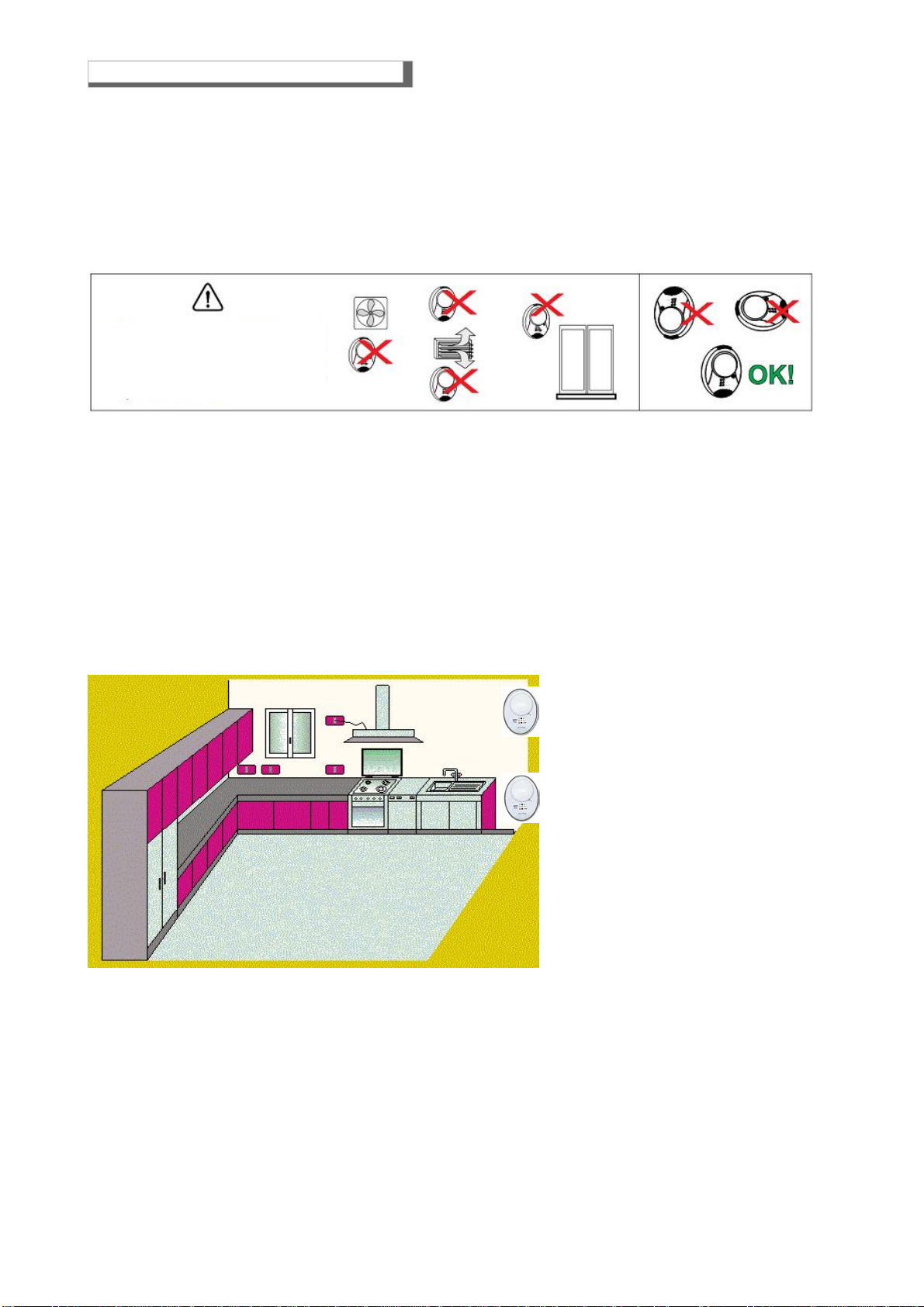

INSTALLATION

When performing the installation, please remind that if you pierce the GS911K container, it will lose its

properties and its conformity to REGULATIONS.

TERMS and EXPECTATIONS: The installation of the GS911K detector, its ordinary and extraordinary

maintenance, and its out of service removal at the end of the functional life guaranteed by the manufacturer,

must be carried out by authorized and/or specialized personnel.

Do not allow it to become wet.

The detector can be seriously damaged when immersed in water.

Do not drop it.

Heavy knocks or falls during transportation or installation can damage the appliance.

Avoid abrupt temperature fluctuations.

Sudden temperature variations can cause condensation and the probe could work poorly.

Cleaning

Never clean the device with chemical products. If necessary, wash with a moist cloth.

Absolutely avoid using any cloth dipped in thinners, alcohol and chemical detergents.

Precautions

Technical Specifications

Functional Features Of Gas Sensors

The installation of the GS911K detector, its ordinary and extraordinary maintenance, and its out of service

removal at the end of the functional life guaranteed by the manufacturer, must be carried out by authorized

and/or specialized personnel.

The CATALYTIC technology sensor duration is guaranteed for 6 years (in clean air).

The detector’s functioning temperature ranges from -10°C to + 40°C.

WARNING!

The CATALYTIC probe does not tolerate a gas detection exceeding 100% of L.E.L., with consequent natural

death of the sensor.

Each immediate puff of gas that exceeds 100% of L.E.L. takes away months of life from the sensor.

The detector must be tested by simulating the presence of gas by issuing it from a pre-calibrated testing

aerosol.

A common cigarette lighter near the sensor does not guarantee excellent functioning.

MAINTENANCE

The user periodically (every 6 months) must perform a check of the operation of the control unit by

spraying a suitable test gas at the base of the probes connected until the alarm condition is reached.

• At least once a year make a more accurate check by a specialist technician.

• Disabling the detector must be carried out by qualified personnel.