9

INNI_USER MANUAL_191225PS

3. INNI 3D Printer Usage Guide

1) Please install the printer in a climate controlled environment (15-35°C) without exposure to water or direct sunlight.

Be sure to use the proper voltage (220V) and to flip the main power switch on the backside of the printer to the

ON position.

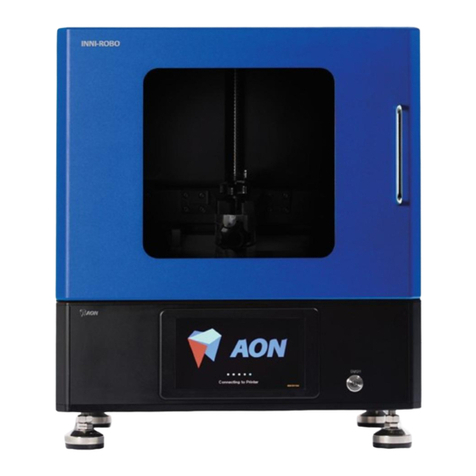

2) Locate the power button next to the LCD console on the front of the printer. Push this button for one or more

seconds until a click is heard. The touch screen panel will display AON’s logo upon start up.

Note: INNI 3D Printer is only compatible with Windows 7 or higher.

3) An exclusive zirconia slurry (BCM-W500) is used for the inlays, crowns, bridges, etc. created by INNI 3D Printer.

To input dental configurations for printing, upload the printing file from a computer that is connected via Wi-Fi/

Ethernet or from an external memory stick/drive via USB.

Note: To create or edit a printing file, you must use AON slicer software.

4) Set the layer thickness to 50μm and the curing conditions to 15 seconds.

5) Add the zirconia slurry (BCM-W500) into the INNI 3D Printer modeling bed and implement Preheat and Blade

Mixing before printing.

6) The build platform will lower, automatically adjusting to the correct height, and the 3D printing process will begin.

Layers (displayed as an image on the touch screen) are laminated one at a time and cured via UV LED light. This

laminating and curing process repeats until the dental restoration shape specified for printing has been created.

7) The printed output should detach easily from the base of platform plate. Remove the supports attached underneath

and finish it off with a cleaning and final heat treatment.

8) Printed restorations created by INNI 3D Printer are to be used as artificial dental or other prostheses for natural

teeth.

9) INNI 3D Printer must use AON’s exclusive zirconia slurry INNI-CERA to produce the desired dental restorations.

Using other products will cause damage to the printer in which case AON cannot be held responsible.

* Please refer to the video on our website for more details.

* If you have further questions, contact our Call Center (+82 70 4304 4996) or send a message to our Support

Team (www.aoninni.com).

User Guidelines