Apeks Regulator User manual

®

Regulator Owner’s Manual

DOC/0258/USA ISSUE 1

Copyright Notice

This owner’s manual is copyrighted, all rights reserved. It may not, in

whole or in part, be copied, photocopied, reproduced, translated or

reduced to any electronic medium or machine readable form without

prior consent in writing from Apeks.

©2005 Apeks

Regulator Owner’s Manual

P/N AP5310AA

Warnings, Cautions and Notes

Pay special attention to information provided in warnings, cautions and

notes, that is accompanied by these symbols:

AWARNING indicates a procedure or situation that, if not

avoided, could result in serious injury or death to the user.

ACAUTION indicates any situation or technique that could

cause damage to the product, and could subsequently result in

injury to the user.

ANOTE is used to emphasize important points, tips, and

reminders.

WARNING: This manual provides essential instructions for

the proper setup, inspection, use, and care of your new

regulator. Because Apeks regulators utilize patented

technology, it is very important to take the time to read

these instructions in order to understand and fully enjoy

the features that are unique to your specific model.

Improper use of your regulator could result in serious

injury or death.

3

Contents

General Precautions & Warnings …………………………………4

Introduction ……………………………………………………………5

Using Enriched Air Nitrox (EAN) ……………………………………6

Overview of Features …………………………………………………8

Second Stage Configuration…………………………………………8

Diver Changeable Exhaust System (DCE) ………………………9

External Second Stage Adjustments ………………………………11

Integrated Venturi System …………………………………11

Inhalation Resistance Control Knob ………………………………12

Egress Second Stage ………………………………………………13

First Stage Environmental Protection ……………………………14

Second Stage Cold Water Protection ……………………………14

Preparation and Setup ………………………………………………15

Hose Attachment ……………………………………………………15

Attaching the First Stage to the Cylinder Valve (Yoke) …………16

Attaching the First Stage to the Cylinder Valve (DIN) …………18

DIN to Yoke Converter ……………………………………………19

Diving with Your Regulator ……………………………………… 20

Pre-Dive Inspection Checklist: ……………………………………20

During the Dive ………………………………………………………21

Diving In Cold Water ………………………………………………22

After the Dive ………………………………………………………… 24

Removal of the Regulator from the Cylinder Valve (Yoke) ……24

Removal of the Regulator from the Cylinder Valve (DIN) ………24

Care & Maintenance ………………………………………………25

Dealer Service & Repair ……………………………………………27

Warranty Information ……………………………………………… 28

Limited Lifetime Warranty …………………………………………28

Restrictions …………………………………………………………29

Returning Your Regulator for Service ……………………………30

ServiceRecord ……………………………………………………… 31

4

General Precautions & Warnings

■Before using this regulator, you must receive instruction and

certification in SCUBA diving from a recognized training agency (or

any U.S. Military or government operated diving school). Use of

SCUBA equipment by uncertified or untrained persons is

dangerous and can result in injury or death.

■This regulator is not configured for commercial use with surface

supplied air.

■Always pressurize the regulator gradually by opening the cylinder

valve SLOWLY.

■NEVER apply any type of lubricant to any part of the regulator or

cylinder valve.

■DO NOT apply any type of aerosol spray to the regulator. Doing so

may cause permanent damage to certain plastic components,

including the second stage housing.

■Factory prescribed service for this regulator must be performed at

least once annually by a factory trained Apeks service technician

who is employed by an authorized dealer. Disassembly, repair, or

first stage adjustment must not be attempted by persons who are

not factory trained and authorized by Apeks.

■DO NOT leave a cylinder standing unsecured with the regulator

attached to the valve. Doing so may cause permanent damage to

the regulator and cylinder valve if the cylinder falls over.

■DO NOT carry the regulator by the first stage when it is connected

to a cylinder. Always carry the cylinder by the cylinder valve or an

attached carrying device.

■When diving in cold water (below 50°F, or 10°C), you must have

received training and certification in the techniques of cold water

diving from a recognized training agency.

5

INTRODUCTION

Congratulations—and thank you—for choosing Apeks. All Apeks

regulators have been designed and manufactured with pride,

according to standards which meet or surpass all requirements for the

BS EN ISO 9001 quality control system.

Your Apeks regulator is covered by Apeks’ Limited Lifetime Warranty

against defects in materials or workmanship. This warranty is only

extended to the original purchaser, however, and is not transferable.

For more information, be sure to read the warranty section of this

manual, and remember to save your sales receipts. Copies of these

receipts must be presented whenever obtaining warranty service.

Perhaps more than any other piece of diving equipment you will own,

your regulator’s function and performance relies greatly on the care

and maintenance it will receive, in addition to regularly scheduled

dealer service. Before you dive with your new Apeks regulator, it is

therefore important to read this manual in its entirety to become

familiar with its features, as well as the correct procedures for setup,

pre-dive inspection and post-dive maintenance.

Please read on to learn how you can obtain the maximum enjoyment

from your regulator, and maintain its like-new performance for many

years to come.

WARNING: Improper use or misuse of SCUBA equipment

may result in serious injury or death. Read and understand

this owner’s manual completely before diving with your

Apeks regulator.

6

USING ENRICHED AIR NITROX (EAN)

WARNING: This section of your owner’s manual contains

important information regarding the use of your equipment

with enriched air (EAN/Nitrox). Do not attempt to use this

product with enriched air until you have read and understand

this section of the manual. To do otherwise increases your

risk of injury or death.

WARNING: Obtain an EAN (Nitrox) Certification. In order to

enjoy the special benefits that EAN/nitrox can provide, it is

extremely important to obtain special training from a

nationally recognized training agency in addition to that

which is provided for openwater scuba.

Your Apeks regulator has been prepared for use with Enriched Air

Nitrox (EAN) where the percentage of oxygen in the EAN does not

exceed 40%. This is possible because each regulator is built to a high

standard of cleanliness using EAN compatible components and

lubricants. In addition, each regulator design has passed stringent

adiabatic compression testing to ensure its safety and compatibility

with increased percentages of oxygen.

If it is your intention to use your new Apeks regulator with EAN (O2not

to exceed 40%), it is imperative that you maintain the internal

cleanliness of the regulator (see section on Care and Maintenance). If

it is your intent to use the regulator interchangeably with breathing air,

the breathing air should be oxygen-compatible or “hyperfiltered”

whereas the condensed hydrocarbons do not exceed 0.1 mg/m3. Your

local authorized Apeks dealer can help you determine whether the

breathing air that they provide meets this criterion.

Standard compressed breathing air, often referred to as Grade E in

the United States, does not necessarily meet this criterion. Grade E

breathing air may contain a certain level of hydrocarbons, including

traces of compressor oils that while not considered harmful to breathe,

can pose a risk in the presence of elevated oxygen content.

7

Passing hydrocarbons through a valve and regulator creates a

cumulative effect where the hydrocarbons build up over time along the

internal passageways of the equipment. When these hydrocarbons

come in contact with high-pressure oxygen enriched air, they can pose

a very real hazard that can lead to combustion.

Therefore, if a regulator has had use with Grade E breathing air, it

should be returned to an authorized Apeks dealer for overhaul service

including hydrocarbon cleaning, prior to being put back into nitrox

service.

Although second stage components are not exposed to high pressure

EAN, Apeks recommends that the same cleaning procedures be

followed for the complete regulator. This prevents the possibility of

cross contamination and guarantees the cleanliness of the entire

regulator.

NOTE: Apeks offers additional models of regulators that are

designed and manufactured for use with enriched air nitrox where

the percentage of oxygen exceeds 40%. For information about

these models, consult your authorized Apeks dealer.

8

OVERVIEW OF FEATURES

The Apeks family of regulators consists of different models which

satisfy a wide range of diving interests; from entry level sport diving, to

advanced diving in more demanding and extreme conditions. By now,

your authorized dealer has already explained to you the specific

features that your particular model offers, and you have made your

purchase after comparing the benefits of these features to your

personal diving needs and interests. Be sure to review this section to

learn more about your model’s features and how to obtain the

maximum benefit from using them. The XTX range offers two features

unique to XTX. The option for either left or right hand hose

configuration and the Diver Changeable Exhaust system (DCE).

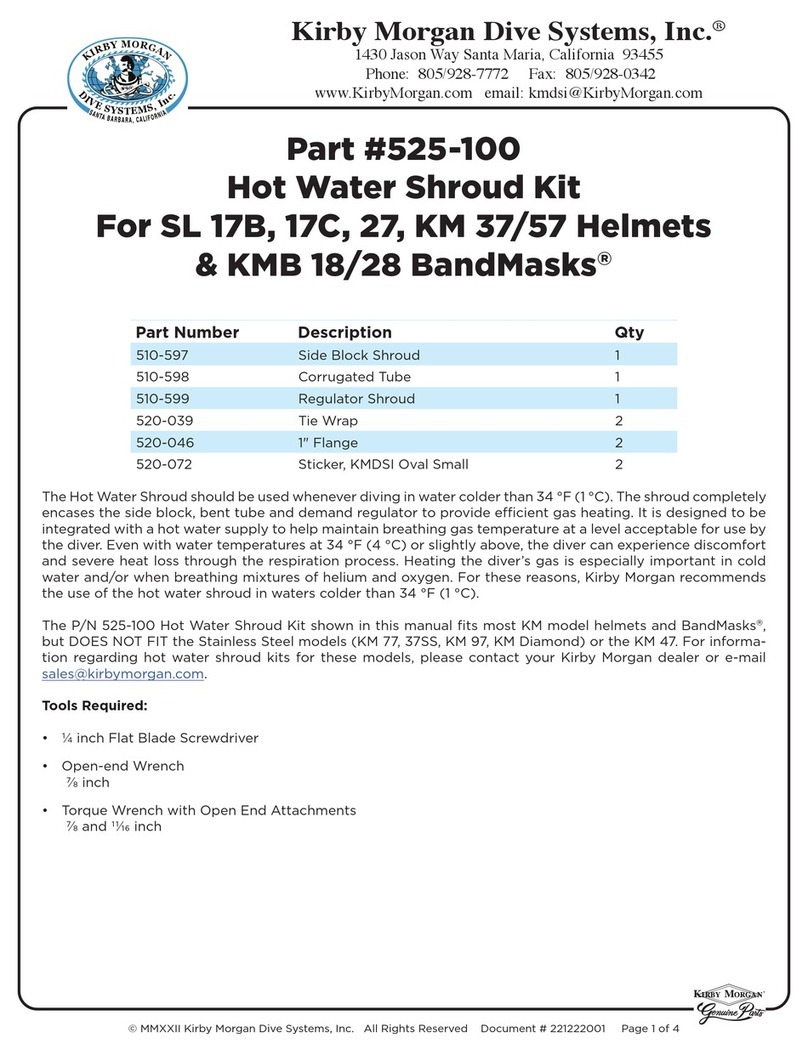

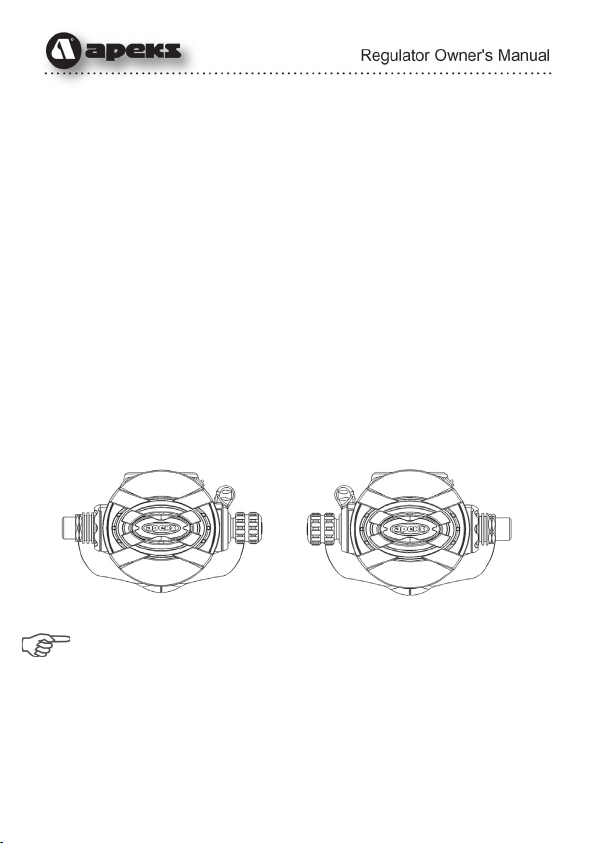

Second Stage Hose Configuration

Apeks XTX regulator range can be dedicated to either left or right

handed use in conjunction with the RVS system (see page 11). The

hose routing can be altered from right hand to left or from left hand to

right by your Authorized Apeks Dealer. This is an extremely useful

feature offering much greater flexibility for personal kit configuration.

Right Hand Left Hand

NOTE: This conversion must only be performed by a factory

trained Authorized Apeks Service Technician who is employed by

an Authorized Dealer. Contact your Authorized Apeks Dealer for

further information on this feature. Disassembly, adjustment or

repair must not be attempted by persons who are not factory

trained and authorized by Apeks.

9

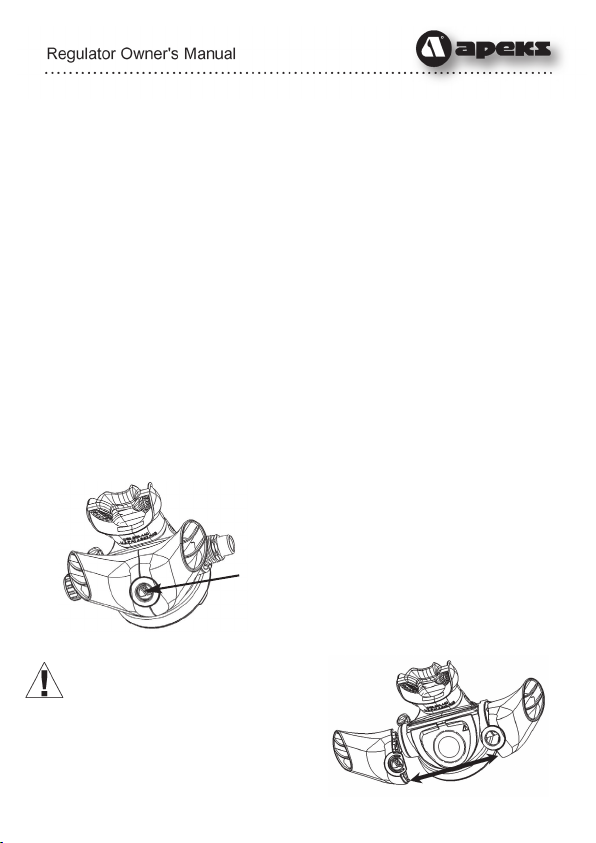

Diver Changeable Exhaust system (DCE)

The Diver Changeable Exhaust (DCE) offers the choice of either a

compact lightweight system or a longer exhaust diffuser. DCE can be

configured to prevent virtually any bubble interference from obscuring

the diver’s view.

The exhaust diffusers can be easily and very quickly changed by

sliding and locking the preferred set into place. Divers can now

configure their own regulator exhaust diffusers for individual dive

conditions or requirements.

By pressing the securing button in the centre of the exhaust diffuser

and at the same time sliding the diffusers apart, they can be removed

quickly and easily.

To attach an alternative set of exhaust diffusers, align the slide

locations as shown and slide each side into place, taking care that the

exhaust diffusers are located securely. When the two diffusers meet

squeeze them together until an audible click is heard from the

retaining button.

1. First gently press the button located

in the center of the exhaust diffuser.

CAUTION! Do not use any tools

to aid the removal of the

exhaust diffusers.

2. Then slide both exhaust diffusers

apart, while keeping the button

depressed.

PRESS HERE

10

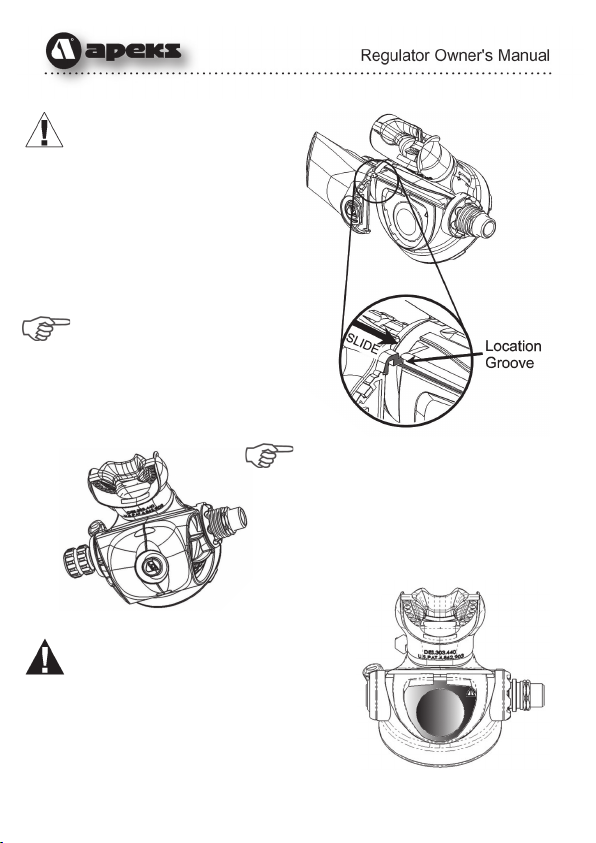

CAUTION! Ensure location

grooves are free from dirt

and debris.

3. Refitting the exhaust diffusers

is carried out by sliding ONE

diffuser at a time onto the

case, once both diffusers are

located on the case, squeeze

the two diffusers together until

you hear an audible “click”.

NOTE: The removal and

refitting of the small exhaust

diffusers is carried out in

exactly the same way as the

large exhaust diffusers.

NOTE: If the exhaust diffusers do

not securely clip together then

they may become detached and

lost. (If required, exhaust

diffusers may be purchased

separately).

WARNING: Do not attempt to use

tools to remove or attach the

exhaust diffusers. After the removal

of the exhaust diffusers care must

be taken to prevent damage to the

exhaust valve. Do not attempt to

poke, pull or touch the exhaust

valve or surrounding area with any

tools. If damage to this part or Shaded area indicates exhaust

valve and surrounding area.

11

surrounding area occurs then this could cause your

regulator to leak, causing serious malfunction or even

personal injury. Care must be taken when securing

alternative sets of diffusers, do not apply excessive force as

damage may occur to the diffusers, exhaust valve or

surrounding area.

External Second Stage Adjustments

External adjustment features offer many advantages, including the

ability to adjust your second stage regulator’s sensitivity as your

diving conditions change. This can allow you to maintain peak

performance throughout every dive, or to desensitize your regulator’s

opening effort at times when you are not breathing from it.

Integrated Venturi System

Apeks second stages are equipped with a

unique Integrated Venturi

System (IVS) control switch

or Reversible Venturi

System (RVS) switch,

located on the opposite side

to the hose connection of

the second stage, that

controls the venturi assist to

reduce sensitivity to freeflow at

the surface and provide

maximum airflow at depth.

While diving set the switch to plus (+) to

achieve maximum venturi assistance for easier breathing.

To prevent the second stage from free-flowing, set the IVS/RVS to the

MIN(–) setting whenever the regulator is out of your mouth.

12

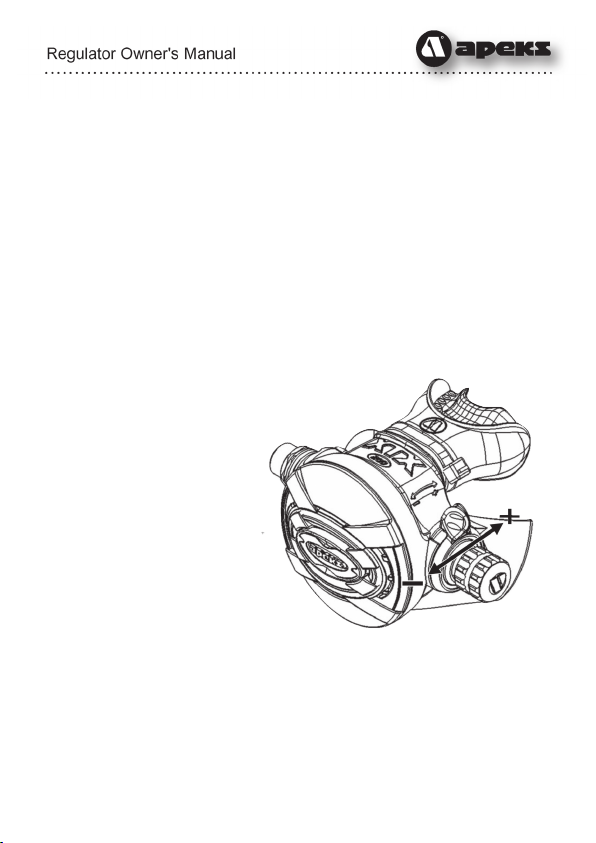

Inhalation Resistance Control Knob

Some second stage models are equipped with an additional

adjustment, which controls inhalation resistance.

This control knob, located beside the

IVS/RVS switch, adjusts the amount of

effort required to start the air flow at

the beginning of the

inhalation cycle. As it is

turned “in” (clockwise),

the opening effort will

increase. This will make

the second stage less

sensitive to sudden

changes in ambient

pressure. Turning the knob

“out” (counter-clockwise) will

decrease the opening effort to

make breathing easier.

This adjustment is particularly useful at deeper depths, or in variable

conditions that affect the opening effort of the second stage, such as

strong currents or while using a diver propulsion vehicle (DPV). You

can use the inhalation control knob to tune your regulator to maintain

its peak performance throughout the course of your dive, or you can

leave it set in its mid-range position and dive with it as you would any

non-adjustable second stage.

For more information on using these adjustments, refer to the section

titled, Diving With Your Regulator, on page 20.

13

Egress Second Stage

The Egress is a low

profile second stage

suitable for use in all

diving conditions, and

can be used either way

up due to its side

exhaust and hose layout.

Therefore the diver can

use the second stage

with the hose routed from

either the left or right

depending on personal

preference and setup requirements.

The Egress second stage is primarily

aimed for use as an alternative air source

second stage although can still be used successfully as a primary

second stage. The Egress also incorporates the patented thermo-

dynamic heat exchanger technology which makes it suitable for diving

in water temperatures below 10ºC, see page 22

14

DIN to Yoke Converter

First Stage Environmental Protection

For diving in contaminated or cold

water conditions, some Apeks first

stages feature a unique “DRY”

environmental sealing system

which completely eliminates the

need for messy silicone oil or

grease filling. An external

diaphragm seals the ambient

chamber from the surrounding sea

water, while a specially designed

piston transfers ambient water

pressure to the internal diaphragm.

This helps to prevent ice from

forming inside the ambient

chamber, and also extends the life of the first stage internal

diaphragm. It is important to remember, however, that this

environmental protection will not completely prevent the second stage

from icing or freezing.

SSecond Stage Cold Water Protection

With the exception of the XTX20, AT20 & T20, Apeks second stages

incorporate a thermo-dynamic heat exchanger at the second stage

hose fitting. This patented (Patent No. U.S. Pat. 5,265,596) feature is

designed to draw in the surrounding water temperature, thereby

warming the valve mechanism and greatly reducing the possibility of

second stage freeze-up.

For important information about diving in cold water, refer to the

section titled, Diving in Cold Water, on page 22.

15

PREPARATION AND SETUP

Hose Attachment

Apeks recommends that you take your regulator to your authorized

dealer for the installation of any accessory items, including

instrumentation, medium pressure (MP) quick disconnect hoses, and

alternative air source second stages. Your dealer can also answer any

questions you may have pertaining to the information in this manual. If

it is not possible to return your regulator and accessories to your

Apeks Authorized Dealer, you may install the accessories yourself

carefully performing the steps in the following procedure.

WARNING: DO NOT connect medium pressure hoses (inflator

hoses and second stage hoses) to high pressure (HP) ports.

This will cause medium pressure hoses to burst when

pressurized, which can result in serious injury. High pressure

ports are identified by the letters ‘HP’ on your regulator and

are mainly used for instrumentation and air integrated

computers.

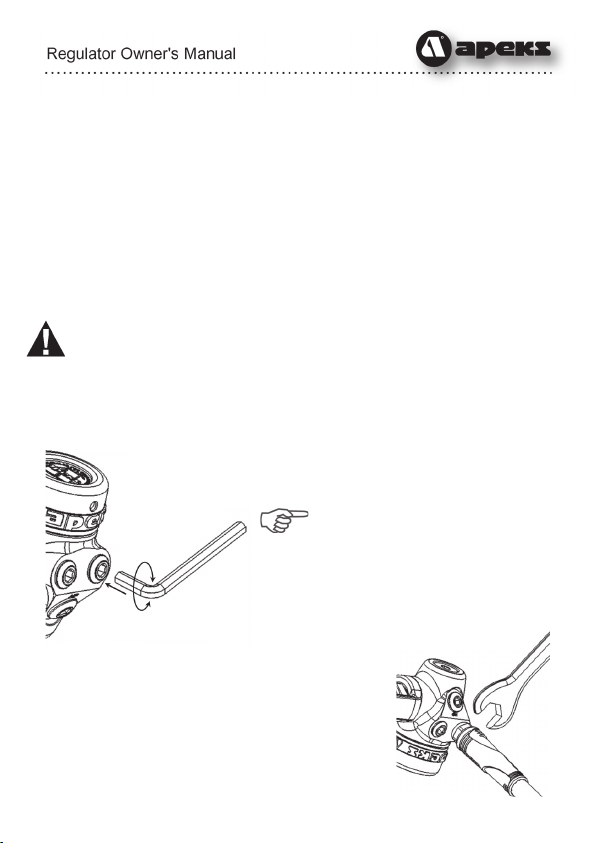

1. Remove the port blanking plug from your first stage

regulator using a 5mm Allen key.

NOTE: Care must be taken

when using a spanner/wrench

when tightening the hose

connections. The spanner can

score and damage the chrome

plating finish of first stage body

around the port area.

2. Ensure the O-ring is present and in good

condition on the hose to be fitted. Screw the

threaded end of the hose into the port making

sure that the thread is screwed in square to the

port. Tighten to 46 kg/cm (40 lbs/in) using an

appropriate sized spanner.

16

1. Check the second stage IVS/RVS control switch to ensure that it is

set to the “MIN” (–) position prior to connecting your regulator to

the tank.

2. If present, gently turn the inhalation control knob “in” (clockwise),

only until it stops. Do not apply

excessive pressure.

3. If you are using a cylinder with

a yoke connection valve,

check the cylinder valve O-ring

is fitted and not worn or

damaged. If you are using a

high pressure cylinder with a

DIN connection valve, remove

the protector cap from the first

stage to inspect the sealing

O-ring of the DIN connector. If

the sealing O-ring is damaged

or worn, replace it before

mounting the regulator on the

cylinder valve.

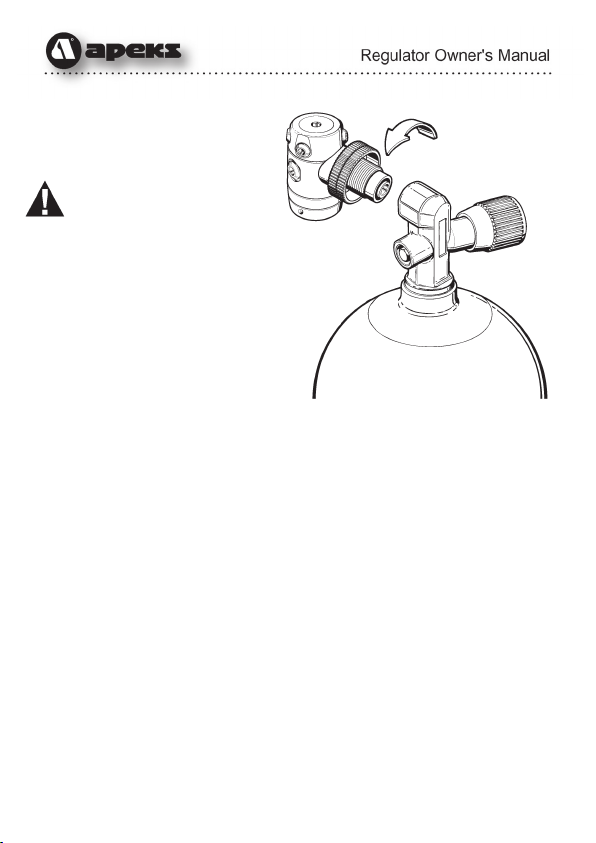

Attaching the First Stage to a

Cylinder Valve (Yoke Connection)

WARNING: OPEN VALVES SLOWLY TO AVOID OVER-

PRESSURIZATION. When pressurizing your SCUBA system,

be sure to open the cylinder valve slowly to minimize the

generation of heat. Failure to do so, with Enriched Air Nitrox

(EAN) present, increases the risk of combustion that can lead

to serious injury or death.

It is considered safe practice, especially when using EAN, to open the

cylinder valve slowly and let the first stage pressurize slowly. Rapid

pressurization causes adiabatic compression of the breathing gas,

which generates heat inside the first stage. Heat, along with elevated

percentages of oxygen and an ignition source (from contamination)

are the ingredients that can cause combustion. This is why it is

17

necessary to keep the interior of the regulator clean and the

percentage of oxygen below 40% along with the slow opening of the

cylinder valve (for regulators over 40% oxygen please see page 6).

To attach a yoke-style first stage to the cylinder valve, follow these

steps:

1. Partially unscrew the yoke screw of the first stage regulator so

that the dust cap can be removed from the air inlet.

2. With the cylinder valve facing away from you, release a small

amount of air from the cylinder by turning the hand-wheel counter-

clockwise to open the valve only slightly. When air is heard exiting,

immediately close the valve. This will clear any moisture or debris

that may be inside the cylinder valve outlet opening. Check the O-

ring is still in place.

3. Place the first stage regulator over the cylinder valve so that the

inlet fitting aligns with the O-ring of the cylinder valve, and the LP

hose of the primary second stage will be routed over the desired

shoulder. While holding the first stage in place, turn the yoke

screw clockwise. Ensure that the yoke screw mates into the small

dimple on the backside of the cylinder valve, and tighten finger-

tight only - do not over tighten.

4. If a submersible pressure gauge is attached to the first stage,

ensure that the gauge is facing away from you. Pressurize the

regulator by slowly turning the cylinder valve handwheel counter-

clockwise. Continue to turn the valve handwheel counter-

clockwise until it is fully open, and then turn it back 1/2turn.

5. Listen near the first stage to check for any leakage. If leakage is

detected, immerse the first stage and cylinder valve while

pressurized to determine the source.

6. If leakage has been detected, follow the procedure for removing

the regulator from the cylinder valve on page 20. If air was leaking

between the first stage and cylinder valve, replace or re-seat the

cylinder valve O-ring as needed and repeat the above procedure.

If leakage persists, return the system to an authorized dealer.

18

Attaching the First

Stage to a Cylinder

Valve (DIN)

WARNING: OPEN VALVES

SLOWLY TO AVOID OVER-

PRESSURIZATION. When

pressurizing your SCUBA system, be

sure to open the cylinder valve slowly

to minimise the generation of heat.

Failure to do so, with Enriched Air

Nitrox (EAN) present, increases

the risk of combustion that can

lead to serious injury or death.

It is considered safe practice,

especially when using EAN, to

open the cylinder valve slowly and let the first stage pressurize slowly.

Rapid pressurization causes adiabatic compression of the breathing

gas, which generates heat inside the first stage. Heat, along with

elevated percentages of oxygen and an ignition source (from

contamination) are the ingredients that can cause combustion. This is

why it is necessary to keep the interior of the regulator clean and the

percentage of oxygen below 40% along with the slow opening of the

valve.

To attach a DIN-style first stage to the cylinder valve, follow these

steps:

1. Remove the protector cap from the cylinder valve, if fitted. With

the cylinder valve facing away from you, release a small amount of

air from the cylinder by turning the handwheel counter-clockwise

to open the valve slightly. When air is heard exiting, immediately

close the valve. This will clear any moisture or debris that may be

inside the threaded cylinder valve opening.

2. Position the first stage near the cylinder valve so that the LP hose

of the primary second stage will be routed over the desired

shoulder. Thread the first stage DIN connector into the cylinder

19

valve and tighten the handwheel by hand until it is lightly snug.

DO NOT use tools to tighten.

3. If a submersible pressure gauge is attached to the first stage,

ensure that the gauge is facing away from you. Pressurize the

regulator by slowly opening the cylinder valve handwheel.

Continue to turn the cylinder valve handwheel until fully open, and

then back 1/2turn.

4. Listen near the first stage to check for any leakage. If leakage is

detected, immerse the first stage while pressurized to determine

the source.

5. If leakage has been detected, follow the procedure for removing

the regulator from the cylinder valve on page 24. If air was leaking

between the first stage and cylinder valve, replace or re-seat the

cylinder valve O-ring as needed and repeat the above procedure.

If leakage persists, return the cylinder and regulator to an

authorized dealer.

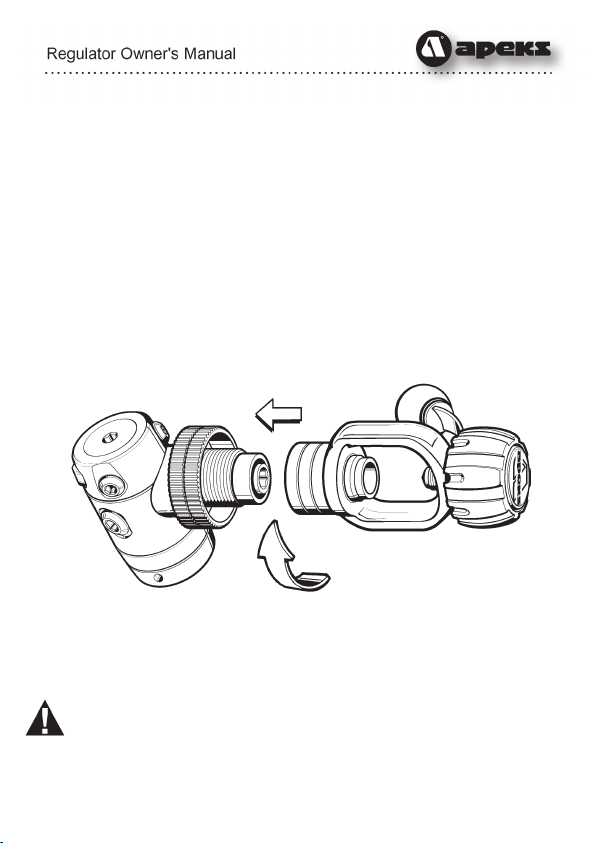

DIN to Yoke Converter

For regulators which may be

used back and forth between Yoke and DIN connections, Apeks offers

a convenient DIN to Yoke converter. First, obtain factory prescribed

installation of the DIN connector through an authorized dealer. Then,

simply attach the converter to connect your regulator to a yoke valve.

WARNING: Adaptors from yoke 1st stage to a DIN cylinder

valve must never be used. This would allow a greater working

pressure to be used than the yoke connector is designed to

take.

Second Stage Cold Water Protection

20

DIVING WITH YOUR REGULATOR

Before each use, it is important to perform a complete pre-dive

inspection of your regulator. NEVER dive with a regulator that shows

signs of damage or unsatisfactory performance until it has received

complete inspection and service from an authorized dealer.

Pre-Dive Inspection Checklist:

1. Carefully inspect all hoses at their fittings to ensure they are

securely connected into their respective ports on the first stage.

Inspect the length of each hose to ensure that the hoses are not

blistered, cut, or otherwise damaged. If hose protectors are

present, slide the protectors back to expose the hose fittings, and

inspect the hoses as described above.

2. Visually inspect both the first and second stage regulators for any

signs of external damage.

3. Environmentally sealed first stages only: Closely inspect the

external sealing diaphragm for any signs of damage or

deterioration that may cause leakage. Check to ensure that the

retainer which holds the external diaphragm in place is tightly

secured.

WARNING: If the external diaphragm shows any signs of

damage or neglect, DO NOT attempt to dive with the regulator

until it has received factory prescribed service from an

authorized dealer. The regulator’s performance may be

compromised, and first stage freeze-up could occur in cold

water conditions.

4. Connect the first stage regulator to a fully charged SCUBA

cylinder. (For mounting instructions, read the Setup section on

pages 15-19.) SLOWLY open the cylinder valve to pressurize the

regulator. Continue turning the valve counter-clockwise until it

stops, and then back 1⁄2turn. This is to ensure that the valve is

completely open.

5. If present, turn the inhalation control knob completely “out”

(counter-clockwise), and then back “in” (clockwise) until the

Table of contents

Other Apeks Diving Instrument manuals

Apeks

Apeks WTX User manual

Apeks

Apeks TX Series User manual

Apeks

Apeks ThermiQ Dry Advanced User manual

Apeks

Apeks ATX 200 User manual

Apeks

Apeks WTX-D User manual

Apeks

Apeks Quantum User manual

Apeks

Apeks XL4 SECOND STAGE User manual

Apeks

Apeks wtx series User manual

Apeks

Apeks wtx series User manual

Apeks

Apeks Black Ice User manual

Apeks

Apeks 388300 User manual

Apeks

Apeks XTX200 User manual

Apeks

Apeks WTX INFLATOR User manual

Apeks

Apeks ThermiQ Dry Advanced User manual

Apeks

Apeks MTX-R User manual

Apeks

Apeks wtx series User manual

Apeks

Apeks Black Ice Twin Cylinder Kit User manual

Apeks

Apeks NS158000 User manual

Apeks

Apeks 427106 User manual

Apeks

Apeks BLACK SAPPHIRE User manual