Apeks 2000PSI THE DUPLEX User manual

Revision Date: 04/11/2019 ©Apeks, LLC 2019

THE DUPLEX TM 2000PSI

BOTANICAL OIL EXTRACTION SYSTEM

INSTALLATION MANUAL

WARNING

FAILURE TO FOLLOW THE SET UP AND OPERATION PROCEDURE

PROVIDED IN WITHIN THIS MANUAL MAY VOID THE EXTRACTION

SYSTEM’S WARRANTY

Apeks Supercritical

150 Commerce Blvd.

Johnstown OH 43031

740-809-1160

service@apekssupercritical.com

www.apekssupercritical.com

Scan this QR code to get

the most recent version of

the installation instructions.

Apeks Supercritical: The Duplex™Installation Manual

2

Revision Date 04/11/2019

Table of Contents

Section Page #

1. Critical Safety Overview............................................................................................................................... 3

2. Before the System Arrives ........................................................................................................................... 4

2.1. System Overview .................................................................................................................................. 4

2.1.1. Diaphragm Compressor ............................................................................................................. 5

2.1.2. Extractor Vessel Stand ............................................................................................................... 6

2.1.3. Separator Vessel/Control Stand ................................................................................................. 7

2.2. General System Specifications ............................................................................................................. 8

2.3. Electrical Requirements ....................................................................................................................... 8

2.4. Facility Requirements ......................................................................................................................... 10

3. When the System Arrives .......................................................................................................................... 10

3.1. Receiving the Crates .......................................................................................................................... 10

3.2. Unpacking Instructions........................................................................................................................ 11

3.3. Set Up and Assembly ......................................................................................................................... 15

3.3.1. Layout/Footprint ...................................................................................................................... 15

3.3.2. Coolant Line and Chiller Setup ................................................................................................. 15

3.3.3. CO2Connections...................................................................................................................... 16

3.3.4. CO2Vent Connections.............................................................................................................. 18

3.3.5. Air Connection ......................................................................................................................... 18

3.3.6. Electrical Connections .............................................................................................................. 20

3.3.7. Chillers ..................................................................................................................................... 21

3.3.8. Email Alerts and Software Updates .......................................................................................... 22

4. Pre-Training Checklist................................................................................................................................ 23

5. References ............................................................................................................................................... 24

6. Appendices................................................................................................................................................ 25

6.1. System Layouts .................................................................................................................................. 25

6.2. Torque Requirements ......................................................................................................................... 29

Apeks Supercritical: The Duplex™Installation Manual

3

Revision Date 04/11/2019

1. Critical Safety Overview

Throughout these instructions, this symbol is used to indicate that the instructions are

critically important to your safety and the safety of your system. Failure to follow the

instructions as written can result in a rapid release of high pressure CO2, potentially causing

equipment damage or harm to workers.

WARNING

Subcritical and Supercritical CO2systems operate under high pressure. Operators must be fully trained and

familiar with the systems. Failure to operate the systems correctly can result in equipment damage and/or bodily

injury.

WARNING

Subcritical and Supercritical CO2systems use large amounts of CO2during operation. Ensure that the system

is installed in a well-ventilated area to prevent buildup of CO2, which can cause asphyxiation. Always use a CO2

monitor to ensure safe operations.

WARNING

Opening a vessel under pressure can result in a rapid release of pressure and ejection of material from inside

the vessel. DO NOT ATTEMPT TO OPEN A VESSEL UNDER PRESSURE! Always make sure a vent path for

the vessel is opened and the corresponding pressure gauge reads zero prior to loosening the vessel closure.

WARNING

Subcritical and Supercritical CO2systems are designed to operate indoors, in a temperature-controlled

environment. Extreme temperatures (below 60°F and above 80°F) will negatively impact the functionality of the

system. The environmental temperature range applies to the system, chiller, pump and CO2bottles.

WARNING

Only use Propylene Glycol and distilled water in the chiller and cooling system. Never use Deionized Water in

the chiller or cooling system.

WARNING

Extraction system components can weigh in excess of 2000lbs and need to be moved carefully. Never attempt

to move system pieces without the proper equipment, failure to do so could result in serious injury or death.

WARNING

Always wear safety glasses when operating and servicing the system.

Apeks Supercritical: The Duplex™Installation Manual

4

Revision Date 04/11/2019

2. Before the System Arrives

2.1. System Overview

Duplex Diaphragm Compressor

Separator Chiller

Extractor Chiller

Extractor Vessel Stand

Separator Vessel Stand

Figure 1: Overhead view of standard layout (Duplex 2000-20Lx20LDU)

Apeks Supercritical: The Duplex™Installation Manual

5

Revision Date 04/11/2019

2.1.1. Diaphragm Compressor

Main Control

Enclosure

HMI

CO

2

Outlet

CO

2

Inlet

Junction Box

Regenerative

Heat

Exchangers

Fork Pockets

Figure 2: Front view of standard layout (Duplex 2000-20Lx20LDU)

Figure 3: Diaphragm Compressor

Apeks Supercritical: The Duplex™Installation Manual

6

Revision Date 04/11/2019

2.1.2. Extractor Vessel Stand

Extractor

B

Extractor

A

Temperature

Control Heat

Exchanger

Flow Switch

Figure 4: Extraction Vessels on Extraction Stand

Apeks Supercritical: The Duplex™Installation Manual

7

Revision Date 04/11/2019

2.1.3. Separator Vessel/Control Stand

Bank 1

Bank 2

E-Stop

Evacuation Valve

Vent Valve

Flow Switch

Collection Cup

Water Valves

Cup Lift

Control Panel Mount

Figure 5: Extraction Vessels and Control Panel

Apeks Supercritical: The Duplex™Installation Manual

8

Revision Date 04/11/2019

2.2. General System Specifications

Extraction

Stand

Separation/

Control

Stand

Diaphragm

Compressor

Extractor

Chiller

Separator

Chiller

Air

Compressor

Max

Pressure

(psi)

2000psi 2000psi 2000psi 100psi 100psi 125psi

Operating

Temperature

(°F)

40°F - 160°F 40°F - 160°F 75°F - 250°F 20°F - 150°F 20°F - 150°F 60°F - 80°F

Dimensions

(in)

WxDxH

58x42x77 53x36x84 74x37x68 25x34x53 19x30x39 14x24x18

Weight (lbs)

1000 lbs

750 lbs

4500 lbs

500 lbs

450 lbs

80 lbs

2.3. Electrical Requirements

Figure 6: Electrical Requirements for Duplex with two Indoor Chillers

Apeks Supercritical: The Duplex™Installation Manual

9

Revision Date 04/11/2019

WARNING

Do not Modify Power Connections

Figure 7: Electrical Requirements for Duplex with one Outdoor Chillers

Apeks Supercritical: The Duplex™Installation Manual

10

Revision Date 04/11/2019

2.4. Facility Requirements

2.4.1. Temperature – The system is designed to run in a climate-controlled facility, where the

temperature is maintained between 60°F and 80°F.

2.4.2. Ventilation and Dust Control – The system should be placed in a well-ventilated environment

that is free from excess dust from other manufacturing operations.

2.4.3. Foundation – Apeks systems are designed to be installed on a concrete (or similarly stable) flat

floor.

2.4.4. Modulation – Apeks Duplex systems are designed to be able to be located in different rooms or

area to isolate different portion of the process. This modulation should be stated during the

purchase process or additional costs and delays may occur.

2.4.5. CO2Vent – Customer is responsible for running rigid tubing from system outlet to a safe vent

location. (NOTE: Vent lines should be rated to the pressure of the system. ⅜" x.035 or

½"x.049 stainless steel tubing recommended. Contact Apeks for part recommendation if

necessary.)

3. When the System Arrives

3.1. Receiving the Crates

3.1.1. Apeks Labeling – Look for an Apeks sticker on the outside of each crate to verify it came

directly from Apeks without tampering. See Figure 1. Note: If no sticker is found, open crate to

verify no damage has occurred during shipping.

Figure 1: Shipping Label

Apeks Supercritical: The Duplex™Installation Manual

11

Revision Date 04/11/2019

3.1.2. TiltWatch – Locate the TiltWatch Plus sensors on the outside of the crate, as shown in Figure

2. Ensure that the crate has not exceeded 30° in any direction. If the crate has exceeded 30°,

do not accept the delivery from the shipping company until contacting Apeks at (740) 809-1160.

3.1.3. Inspecting Crates for Damage – Prior to opening the crate(s), verify that there is no external

damage. If damage is found, do not accept delivery from the shipping company without noting

any damage on Proof of Delivery. In addition, call Apeks at (740) 809-1160 to report damage

and start the reporting process with the shipping company.

3.2. Unpacking Instructions

WARNING

Heavy Components. Do not attempt to lift without the proper equipment.

3.2.1. Uncrating the Extractor Stand and Separator/Control Stand

3.2.1.1. Tools Needed: Drill with Philips head bit, pry bar and hammer.

3.2.1.2. Remove the sides and top of the shipping crate.

3.2.1.3. Remove the wooden tie downs that keep the system attached to the skid. See Figure 3.

Figure 2: TiltWatch Label

Apeks Supercritical: The Duplex™Installation Manual

12

Revision Date 04/11/2019

3.2.1.4. Carefully use a forklift to remove the stand from the skid and attach the four leveling feet to

each stand. See Figure 4.

3.2.1.5. Once the system is on the ground use these feet to get the system level and then snug the

jam nut against the stand to secure the feet.

Wood Tie-Downs

Jam Nut

Figure 3: Wood Tie-Downs

Figure 4: Leveling Feet

Apeks Supercritical: The Duplex™Installation Manual

13

Revision Date 04/11/2019

3.2.2. Uncrating the Diaphragm Compressor

3.2.2.1. Remove the sides and top of the shipping crate. See Figure 5.

3.2.2.2. Remove lag screw/bolts that keep the pump attached to the skid.

3.2.2.3. Carefully use a forklift to remove the pump from the skid and attach the four rubber

vibration dampening feet to the four corners of the pump. See Figure 6.

Figure 5: Diaphragm pump on skid

Figure 6: Vibration Dampening Feet

Apeks Supercritical: The Duplex™Installation Manual

14

Revision Date 04/11/2019

3.2.3. Uncrating the Chillers

3.2.3.1. Remove the sides and top of the shipping crate.

3.2.3.2. Remove the wooden blocks holding the chiller to the base.

3.2.3.3. Use a forklift or the provided ramp to remove the chiller from the base.

3.2.3.4. When chiller is in final location, lock the wheels.

3.2.4. Verifying Apeks Shipper – Every Apeks machine is sent with a shipper that will contain quality

control checklist and a packing slip. Verify that all items on the packing slip (example below)

have been received. Contact Apeks if there are items missing.

Apeks Supercritical: The Duplex™Installation Manual

15

Revision Date 04/11/2019

3.3. Set Up and Assembly

3.3.1. Standard Layout/Footprint with Indoor Chiller

3.3.2. Coolant Line and Chiller Set Up

3.3.2.1. Separator Coolant Loop – The separator coolant loop will incorporate the Separator

Chiller, the diaphragm compressor and the Separator Vessel/Control Stand.

3.3.2.1.1. Chiller Outlet to Diaphragm Compressor – The hose on the chiller outlet will

connect to the oil heat exchanger on the diaphragm pump.

3.3.2.1.2. Diaphragm Compressor to Separator Stand – The hose coming from the brass

tee on the diaphragm compressor will connect to the water valve with the flow switch

on the separator stand.

3.3.2.1.3. Separator Stand to Chiller Inlet – The hose on the chiller outlet will connect to the

water valve without the flow switch on the separator stand.

3.3.2.2. Extractor Coolant Loop – The extractor coolant loop will incorporate the Extractor Chiller

and the Extractor Vessel Stand.

3.3.2.2.1. Chiller Outlet to Extractor Stand – The hose on the chiller outlet will connect to the

temperature control heat exchanger on the extractor stand.

3.3.2.2.2. Extractor Stand to Chiller Inlet – The hose on the chiller inlet will connect to the

flow switch on the extractor stand.

3.3.2.3. Initial Fill – This step will need to be performed after the chillers electrical connection has

been made and the chiller is connected to the main control enclosure. (See Electrical

Requirements section, page 21.)

Figure 7: Standard Layout/Footprint with Indoor Chiller

Apeks Supercritical: The Duplex™Installation Manual

16

Revision Date 04/11/2019

3.3.2.3.1. Once the water line connections and electrical connections have been made, fill the

chiller reservoir with 95/5 mix of water/propylene glycol.

3.3.2.3.2. From the manual screen, start the desired chiller.

3.3.2.3.3. Continue to fill the chiller reservoir with the same fluid mix as the chiller pump fills the

system with fluid.

3.3.2.3.4. Once the reservoir has stopped receding, top off reservoir and allow the chiller to

continue to run as the chiller pump primes.

3.3.2.3.5. This priming should continue until the pressure in the chiller reaches operational

level: 45psi for the extractor chiller, 78psi for the separator chiller. Note: if chiller over

pressurizes, partially close the ball valve on the back of the chiller to reduce pressure

to the operating pressure.

3.3.2.3.6. As the pressure increases the reservoir level may decrease so top off as necessary.

3.3.2.3.7. Once the chillers are up to pressure, the extractor chiller is ready to run and can be

turned off.

3.3.2.3.8. The separator chiller loop will need separator bank 2 filled with fluid

3.3.2.3.8.1. Go to the manual screen and click the “Fill Separator Bank 2 WATER” button.

Note: If this button does not appear on the screen click on the “Manual Mode”

button.

3.3.2.3.8.2. As the pump fills the second separator bank the reservoir will need to be filled

again and the pump may need to re-primed if the pressure drops.

3.3.3. CO2Connections – There are four CO2lines to be connected on the Duplex system, two

between the Extractor and Separator Stands and one each between those stands and the

Diaphragm Compressor.

3.3.3.1. Separator Vessel Stand to Diaphragm Compressor – This connection is a 36"long

stainless steel braided flexible line with ¾"compression fittings.

Figure 8: Separator Stand to Compressor

Apeks Supercritical: The Duplex™Installation Manual

17

Revision Date 04/11/2019

3.3.3.2. Diaphragm Compressor to Extractor Vessel Stand – This connection is a 36"long

black nylon flexible line with ½"compression fittings.

3.3.3.3. Extractor Vessel Stand to Separator Vessel Stand – These connections are 18"long

stainless steel braided flexible lines with 3/8"compression fittings. Connect 1 and 2 on the

extractor stand to 1 and 2 on the separator stand respectively.

1

2

Figure 9: Diaphragm Compressor to Extraction Vessel

Figure 10:Extraction Vessel Stand to Separator Vessel

Apeks Supercritical: The Duplex™Installation Manual

18

Revision Date 04/11/2019

3.3.4. CO2Vent Connection – Apeks extraction systems come with rigid vent tubing all connected to

one outlet located near Valve 0 underneath the Motor Starter Enclosure. The customer is

responsible for running this vent line to desire location in build and should use material rated to

the pressure of the system (3/8"x.035 or ½ " x.049 stainless steel tubing recommended).

Connection is a 3/8"Swagelok compression fitting.

3.3.5. Air Connections – There are over twenty-five air operated ball valves that are used to control

the CO2flow path throughout the system. These valves are controlled by an air manifold on the

back of the control panel mount.

3.3.5.1. Air Manifold – The air manifold receives electrical signals from the controller and uses

compressed air to open valves. See Figure 12.

1

2

Figure 11:Vent Connection

Figure 12:Manifold Air ouputs

Apeks Supercritical: The Duplex™Installation Manual

19

Revision Date 04/11/2019

3.3.5.2. Separator Vessel Stand to Extractor Vessel Stand – There are thirteen ¼"red airlines

that run between the separator and extractor stand. These lines are connected with a

push-to-connect coupling and labeled on both sides. Fully insert the tubing into the

coupling to connect. See Figure 13.

3.3.5.3. Separator Vessel Stand to Diaphragm Compressor – There is one ¼" red airline that

runs between the separator stand and the diaphragm compressor. This line is connected

with a push-to-connect coupling and labeled on both sides. Fully insert the tubing into the

coupling to connect. See Figure 14.

Figure 13:Airline connections

Figure 14:Airline connection to Compressor

Apeks Supercritical: The Duplex™Installation Manual

20

Revision Date 04/11/2019

3.3.6. Electrical Connections

3.3.6.1. Harting Connector – This connector carries all the signals from the pressure transducers,

flow switches, etc. back the main control enclosure (excluding the thermocouples). These

are quick connecting electrical connections that plug in and are secured with snaps on

each side as seen in Figure 15.

3.3.6.2. Thermocouple Connector – This connector carries the signal from the thermocouples

back the main control enclosure. This connector is a plug style connection as seen in

Figure 16.

3.3.6.3. Separator Vessel Stand to Extractor Vessel Stand

3.3.6.3.1. Junction Box 3 (Extractor B Side)

3.3.6.3.1.1. Harting Connector #1214CBL1.

3.3.6.3.1.2. Thermocouple Connector #1709CBL1.

3.3.6.3.1.3. Thermocouple Connector #1809CBL1.

3.3.6.3.2. Junction Box 2 (Extractor A Side)

3.3.6.3.2.1. Harting Connector #1511CBL2.

3.3.6.3.2.2. Thermocouple Connector #1805CBL1.

3.3.6.4. Separator Vessel Stand to Diaphragm Compressor (Junction Box 1)

3.3.6.4.1. Harting Connector #1209CBL1.

3.3.6.4.2. Thermocouple Connector #1705CBL1.

Figure 15: Harting Connector

Figure 16: Thermocouple Connector

Other manuals for 2000PSI THE DUPLEX

1

Table of contents

Other Apeks Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Endress+Hauser

Endress+Hauser 51517656 CleanFit H CPA 475 operating instructions

ABB

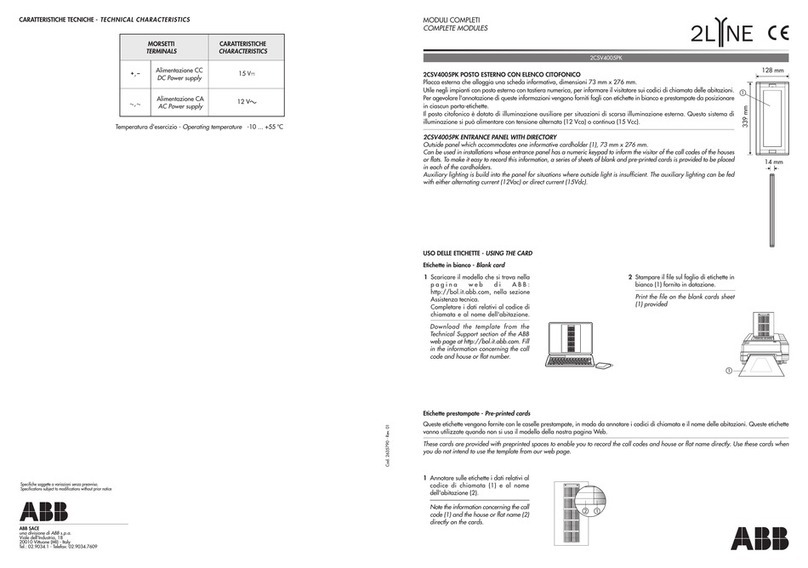

ABB 2LINE 2CSV4005PK Assembly instructions

RINGSPANN

RINGSPANN FRS Series Installation, Lubrication, Maintenance Instructions

Kaller

Kaller KF2 1500 - 7500 user guide

Yamaha

Yamaha SIGMA-G5SII Service information

Global Industrial

Global Industrial B237006 Assembly instructions