Table of Contents

1Overview...................................................................................................... - 3 -

2Technical Specifications ................................................................................ - 4 -

2.1 Technical Parameters.................................................................................................- 4 -

2.2 Others.......................................................................................................................- 4 -

3Instrument Description................................................................................. - 5 -

3.1 Instrument Overview ................................................................................................- 5 -

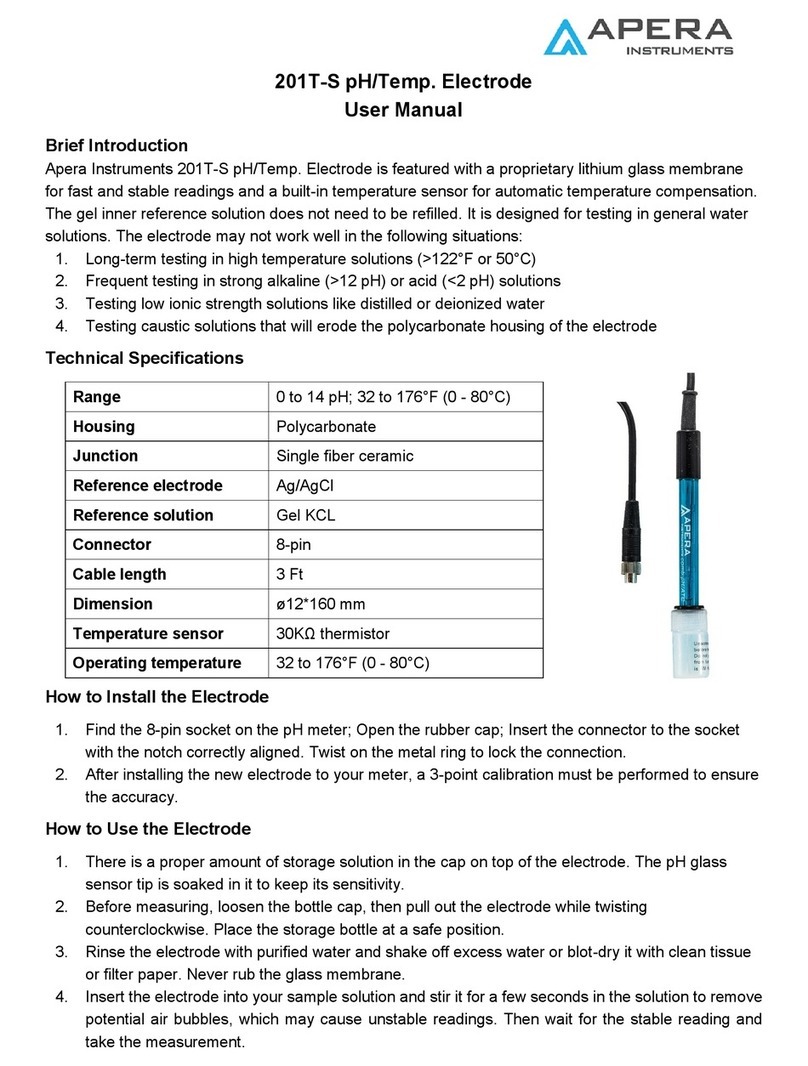

3.2 Meter and Accessories ..............................................................................................- 6 -

3.3 Display......................................................................................................................- 7 -

3.4 Keypad......................................................................................................................- 7 -

3.5 Battery Installation....................................................................................................- 8 -

4Meter Calibration ......................................................................................... - 8 -

4.1 Calibration Standards ................................................................................................- 9 -

4.2 Calibration Procedure................................................................................................- 9 -

4.3 Calibration Notes ....................................................................................................- 10 -

5Turbidity Measurement.............................................................................. - 11 -

5.1 Sample Vial Handling...............................................................................................- 11 -

5.2 Measurement Preparation ...................................................................................... - 11 -

5.3 For Single Measurement..........................................................................................- 12 -

5.4 For Continuous Measurement .................................................................................- 12 -

5.5 Measurement Notes................................................................................................- 12 -

6Warranty.................................................................................................... - 15 -