CLEANING

In this section, we describe the procedures to clean and decontaminate the pump. It is

important to follow these procedures before using the system on patients.

The cleaning task is required at least once a week to maintain personal hygiene.

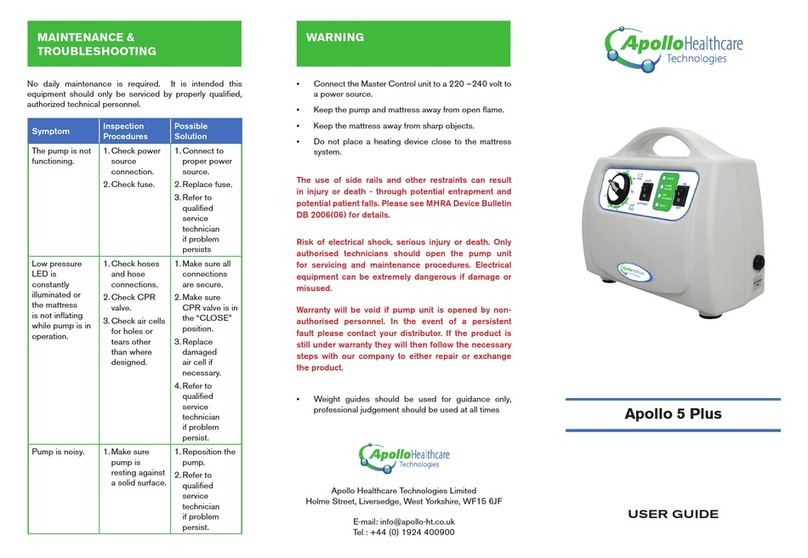

Pump

DO NOT immerse or soak the pump.

Check for external damage and move the pump to the cleaning area.

Place the pump on a work surface and spray or wipe the outside of the case wi t h

quaternary ammonium solution.

DO NOT spray any cleaning solution directly on the surface of the pump.

DO NOT use a Hypo carbonate or Phonetic based cleaning solution as this may cause

damage to the case. Allow the solution to incubate for 10 minutes or accordingly as

stated by the cleaning product used.

Wipe case with a clean cloth. Make sure all areas are clean (top and bottom, both

sides).

Spray cloth with cleaning solution and clean faceplate. DO NOT allow excess cl eani ng solution

on faceplate or control panel. (If solution gets inside, damage will occur.) Allow

surface to thoroughly dry after cleaning.

After the pump is thoroughly cleaned and dried, proceed to plug in the pump and test to

see if it runs normally.

Unplug the pump and store with proper identification tag.

Mattress

Brush off or wipe down all surfaces of the cover sheet with soap and water bef or e wetting

with any liquid disinfectant.

Any obvious blood spots should be wet thoroughly with 1:9 Hypochiorite solution

(1 part bleach to 9 parts water) and allow drying for at least 10 minutes. Then blot with

a clean, damp cloth.

Unzip the top cover from the mattress.

Brush or wipe down all surfaces with soap and water before applying any liquid.

Covers are immersed and soaked in disinfectant for the required incubation time.

After pre-soaking, the cover is rinsed through a regular cycle in a washer with no soap then

laundered with mild detergent (wash temperature 93°F, rinse temperature 78°F or on the

coldest setting).

Covers are aerated until they are fully dry. (Drying temperature range 90-120°F or on the

coldest setting.)

The air cells are unsnapped from one side and are sprayed on all sides with a

disinfectant. Let it sit for the required incubation time and wipe down with a clean cloth.

(Make sure to disconnect all the air cells, one by one, and spray the disinfectant on all

sides, including all the connecting tubes and hoses. Let it sit for least 10 minutes. )

If there is a base after you remove all the air cells, the base has to be sprayed down with

the disinfectant, inside and outside. Let it sit for the required incubation time and wipe

down with a cloth.

Repeat the process with the tubing set: spray, incubate, and then wipe clean.

The carrying bag should be turned inside out and completely wiped down using the

disinfectant solution.

Allow it to thoroughly air dry. Once the inside is dry, turn it back: wipe down the outside of

the bag with disinfectant.

Dry the mattress on a SUNLESS area after cleaning.

HANDLING AND STORAGE

Lay the mattress out flat and upside down.

Roll from the foot end towards the head end; the foot-end strap can then be st ret ched

around the rolled mattress to prevent unrolling.

Do not fold, crease or stack the mattress.

Follow the national requirement to dispose the pump.

MAINTENANCE

General

Check the power cord and plug to see if there are abrasions or excessive wear.

Check the mattress cover for signs of wear or damage. Ensure the mattress cover and tubes

are connected together correctly.

Plug in the pump and check the airflow from the hose connection port. The airflow

should alternate between ports every half-cycle time.

Check the air hoses to see if there are kinks or breaks. For replacement, pl ease

contact your local agent or dealer.

Make sure the mattress tube is well connected.

Check the pump and make sure both power and power indicator are off when the

switch is turned off.

Low pressure

Examine if there is air leakage between the pump and the mattress connections or from the

air mattress tubes:

Check connectors between the air mattress and pump. If there is any

disconnection, please reconnect it.

Check the CPR Valves. Ensure their outlets are sealed.

Check the air-connecting tubes. Ensure each single cell is not broken.

Turn the pressure-adjust knob to Firm. Keep the tubes fully inflated and inspect for ai r

leakage.

Check if there is any air leakage from cells. Ensure no leakage occurs. If any leakage

occurs, please contact your local agent or dealer.

Warranty / Servicing

Both pump and mattress carry a 2-year warranty in subject to being serviced in accordance to Apollo

Healthcare Technologies service manual.

SERVICING YOUR SYSTEM

The mattress system should be serviced every 12 months by Apollo Healthcare Technologies or approved

personnel using genuine Apollo Healthcare Technologies spare parts.

Compressor/ Bellows should be changed. Filters should be changed.