__________________________________________________________________________________________________________

___________________________________________________________________________________________________________

Page 3of 20

Table of Contents

REVISION HISTORY .......................................................................................................................................... 2

1. INTRODUCTION TO THE DURA SPARK SOUND SOURCE..................................................................... 5

2. COMPONENTS......................................................................................................................................... 6

3. THEORY OF OPERATION ......................................................................................................................... 6

4. DURA SPARK L80 POWER LEVELS.......................................................................................................... 6

5. PULSE SIGNATURE................................................................................................................................... 7

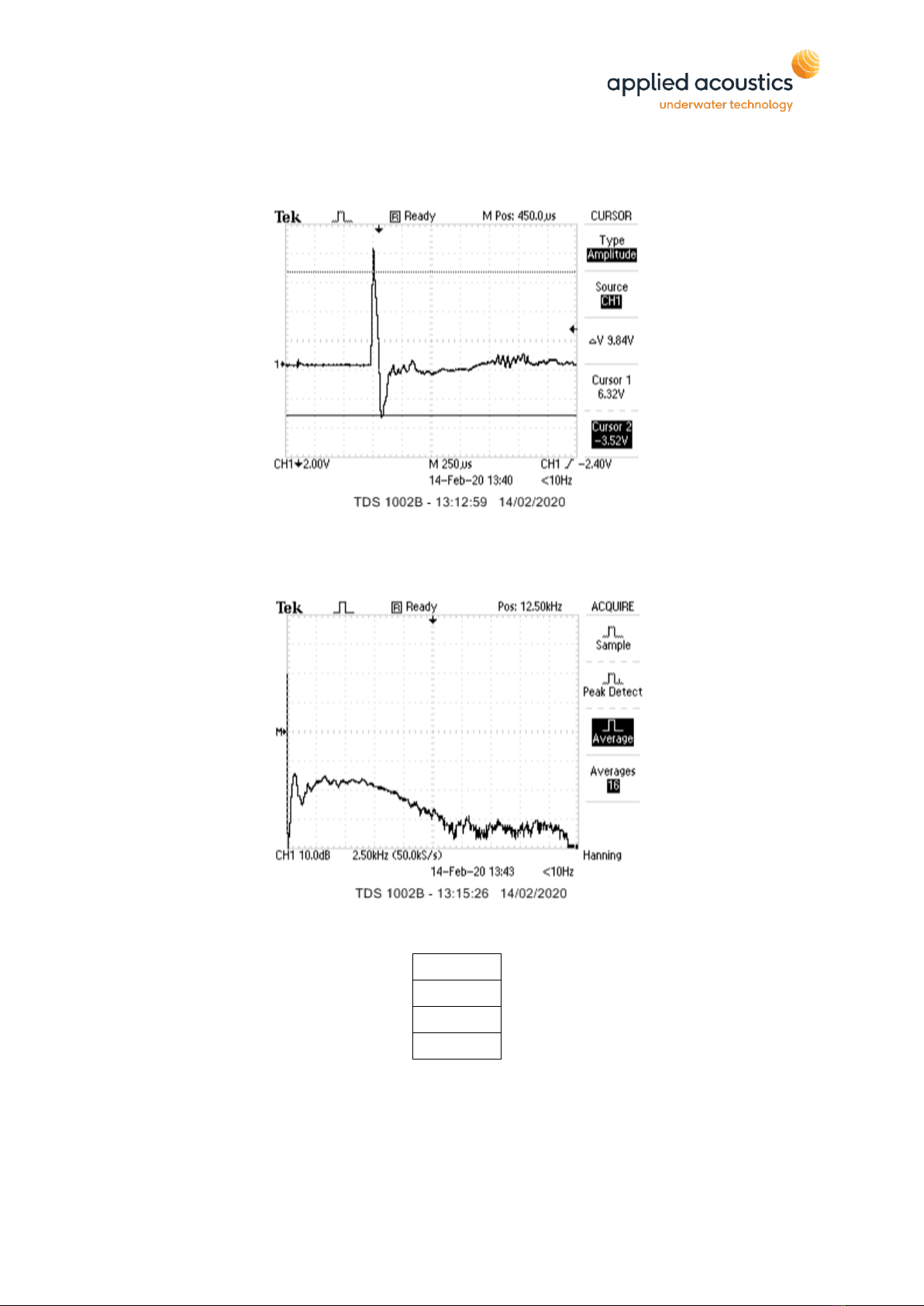

100J................................................................................................................................................................ 7

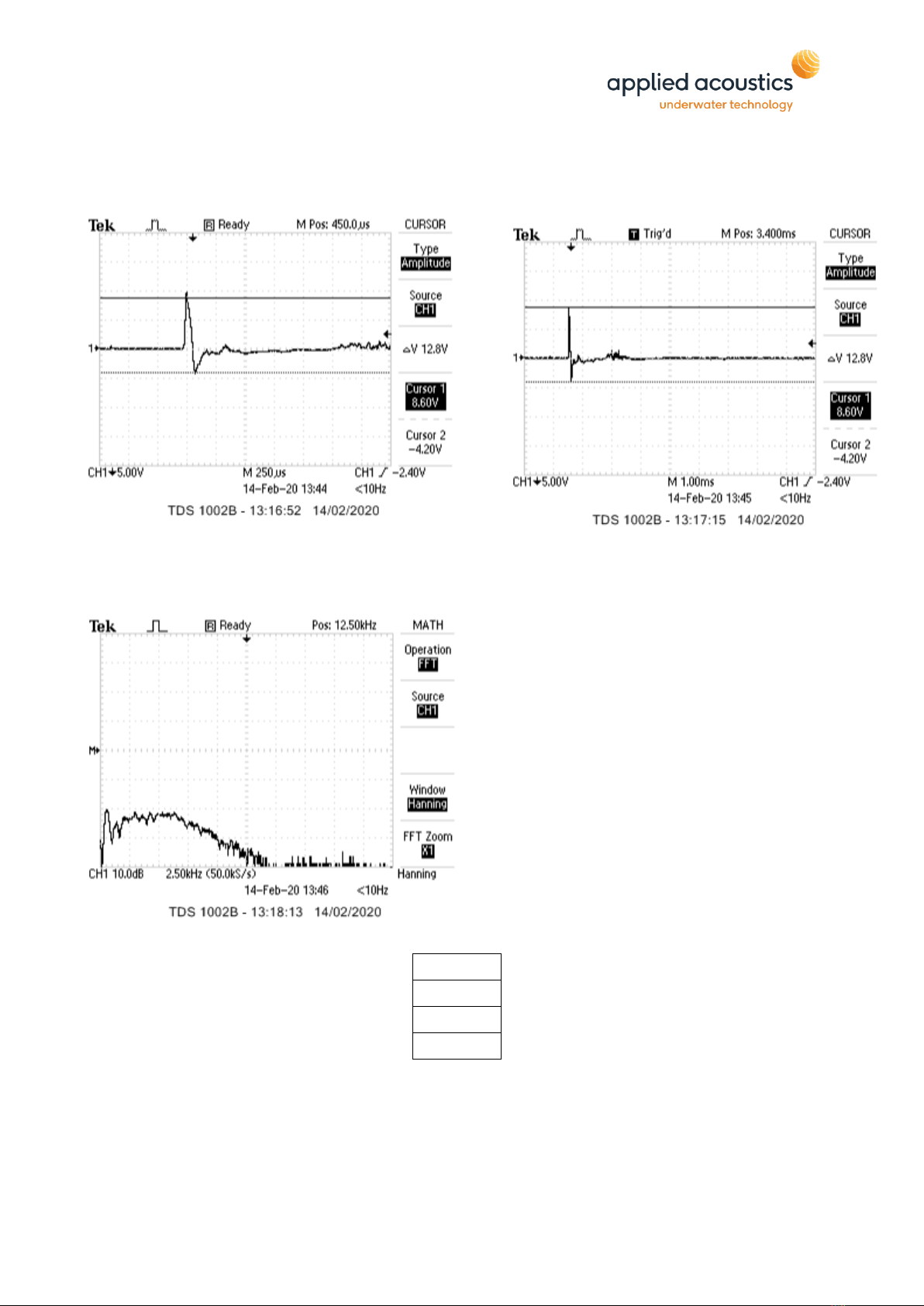

200J............................................................................................................................................................... 8

300J............................................................................................................................................................... 9

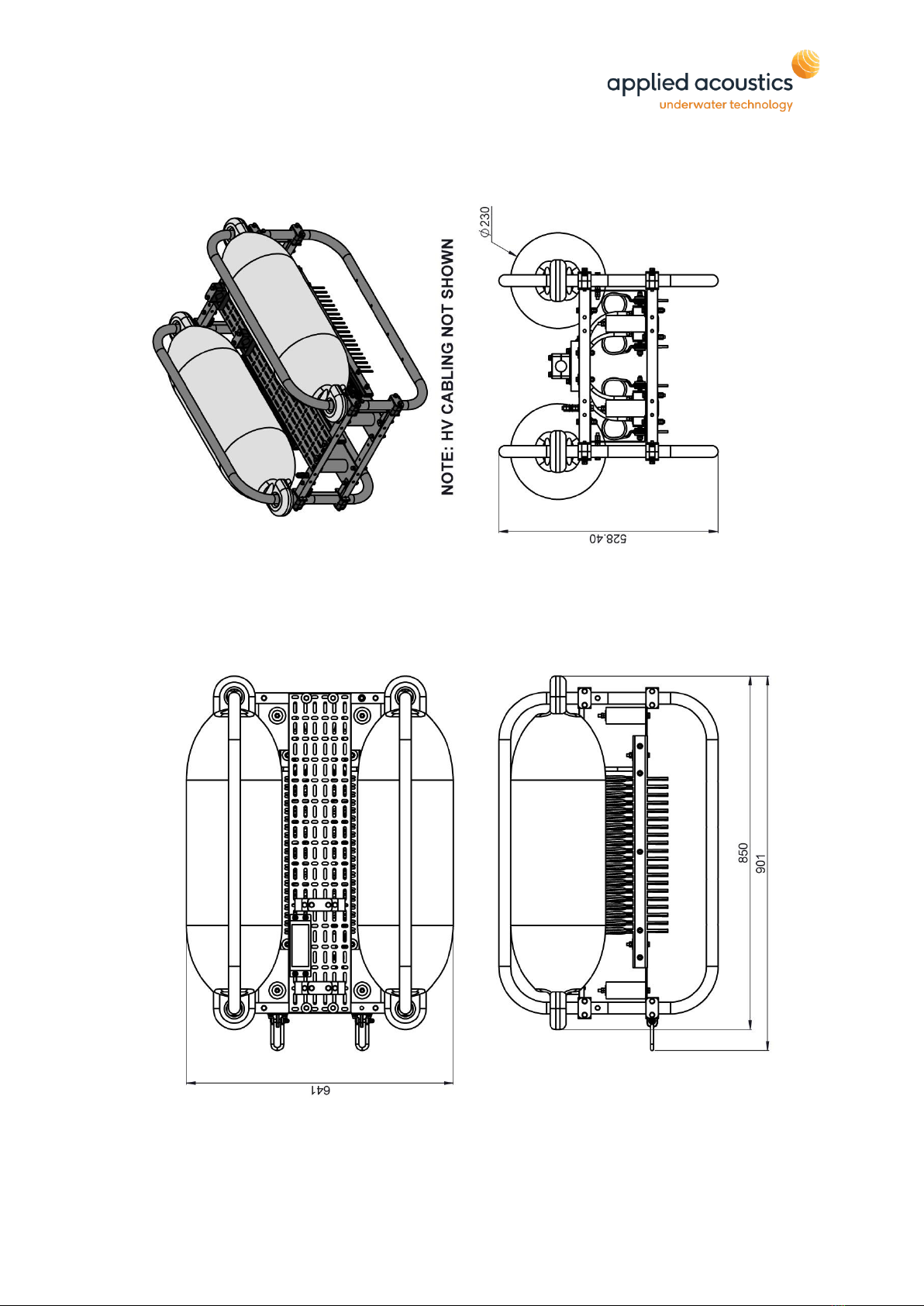

6. DIMENSIONS.......................................................................................................................................... 10

7. CABLING AND CONNECTIONS ............................................................................................................ 11

HVJ2001 JUNCTION BOX LAYOUT AND CONNECTIONS........................................................................................ 11

HVJ3001 JUNCTION BOX LAYOUT .................................................................................................................... 11

HVJ3001 JUNCTION BOX BUZZ BAR ARRANGEMENT ........................................................................................... 12

DURA SPARK 80 -40 TIP ARRANGEMENT........................................................................................................... 12

DURA SPARK 80 -80 TIP ARRANGEMENT........................................................................................................... 13

HVJ3000 JUNCTION BOX INTERLOCK WIRING ................................................................................................... 14

HVC2002 CABLE........................................................................................................................................... 15

8. DEPLOYMENT / INSTALLATION ............................................................................................................ 16

9. MAINTENANCE PROCEDURES.............................................................................................................. 17

TIP WEAR........................................................................................................................................................ 17

MECHANICAL .................................................................................................................................................. 17

10. END OF LIFE RECYCLING / DISPOSAL .................................................................................................. 17

11. SPECIFICATION ..................................................................................................................................... 18

PHYSICAL........................................................................................................................................................ 18

ELECTRICAL SPECIFICATION ............................................................................................................................... 18

COMPATIBILITY ................................................................................................................................................ 18

PERFORMANCE ................................................................................................................................................ 18