Instruction manual CL, SL, SLWN, SR, SRWP SMART

3

Contents

1. INTENDED USE AND IMPORTANT INFORMATION FOR THE USER.........................................................6

2. PACKAGE CONTENTS..................................................................................................................................7

3. BEFORE THE FIRST USE..............................................................................................................................8

3.1. Installation of shelves ...........................................................................................................................10

3.2. Remarks on the placement of samples.................................................................................................10

3.3. Closing chamber door...........................................................................................................................11

4. DESCRIPTION OF THE DEVICE..................................................................................................................11

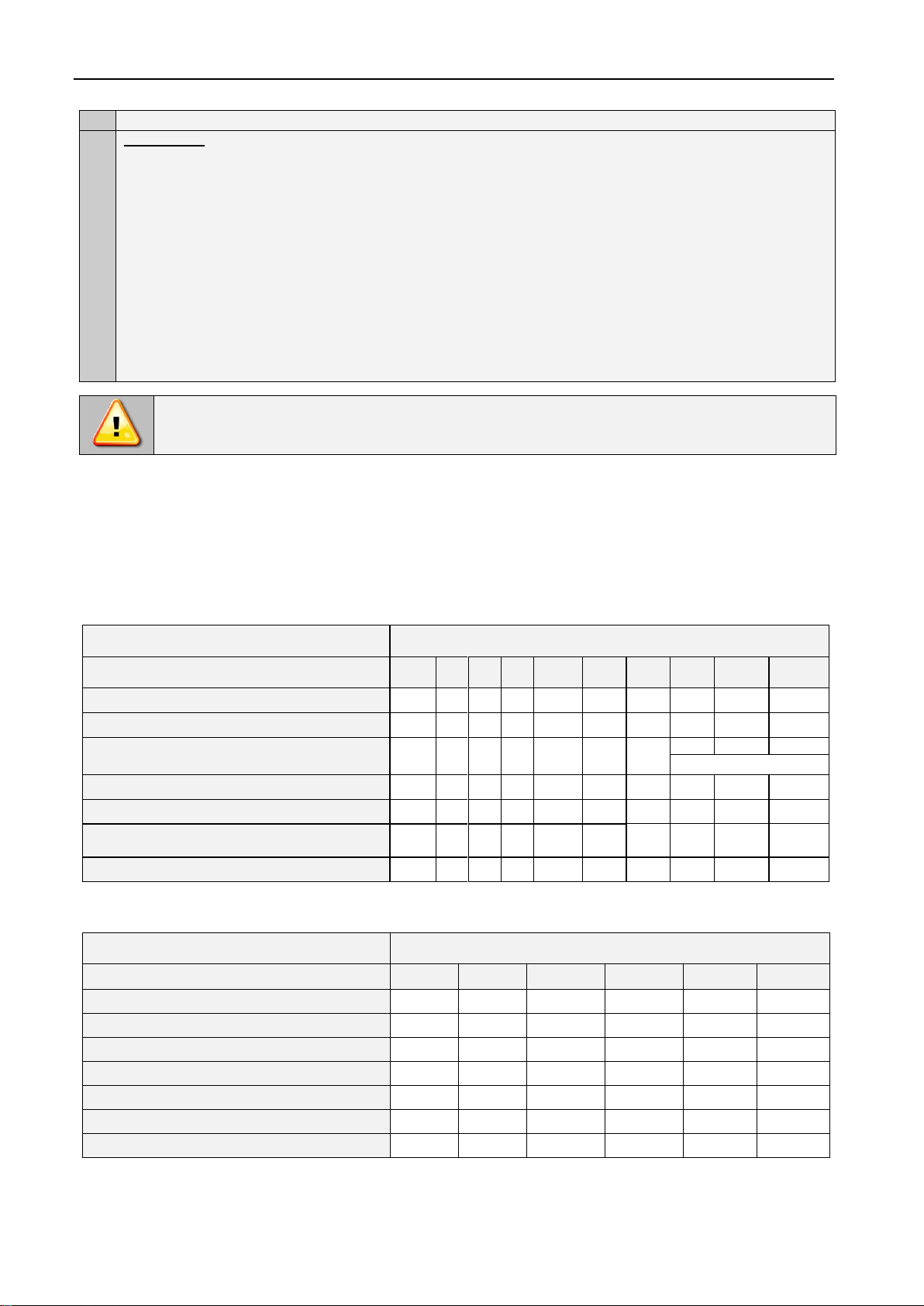

4.1. Design of CL, SL, SR, SRWP devices..................................................................................................11

4.2. Design of SRWP devices......................................................................................................................14

5. DEVICE EQUIPMENT (standard and optional)..........................................................................................16

5.1. External door with viewing window (optionally for CL, SL, SR).............................................................16

5.2. Internal glass door (standard for CL)....................................................................................................16

5.3. HEPA filter (optionally for all units) .......................................................................................................16

5.4. Internal socket (optionally for CL).........................................................................................................17

5.5. Door lock (standard for all units)...........................................................................................................17

5.6. Access port for external sensor (standard for all units).........................................................................18

5.7. Open door alarm (standard for all units) ...............................................................................................18

5.8. Internal light (optionally for all units) .....................................................................................................18

5.9. USB port (standard for all units)............................................................................................................19

5.10. Display battery backup (optionally for CL, SL, SLWN, SR, SRWP)......................................................19

6. DEVICE OPERATION...................................................................................................................................20

6.1. External memory (USB flash drive).......................................................................................................20

6.2. First boot...............................................................................................................................................20

6.3. Main screen.................................................................................................................................21

6.3.1. Information panel..............................................................................................................................22

6.3.2. The meaning of icons and symbols..................................................................................................24

6.3.3. Upper expandable and configurable menu.......................................................................................26

6.3.4. Alarm bar..........................................................................................................................................28

6.4. Quick Program......................................................................................................................................28

6.5. Programs.....................................................................................................................................30

6.5.1. Creating / editing a program.............................................................................................................31

6.5.2. Segments edition..............................................................................................................................32

6.5.3. Protection class................................................................................................................................35

6.5.4. Temperature protection class 3.1 (optionally)...................................................................................35

6.5.5. Priority..............................................................................................................................................35

6.5.6. Loop .................................................................................................................................................36

6.5.7. SR and SRWP devices –factory predefined sterilization programs.................................................36

6.6. Starting the program.............................................................................................................................36

6.6.1. The first way.....................................................................................................................................36

6.6.2. The second way...............................................................................................................................38