1

1.About This

1.1 Manual Purpose

This manual describes the assembly, installation, operation and troubleshooting of this unit. Please read this

manual carefully before installations and operations. Keep this manual for future reference.

1.2 Scope

This manual provides safety and installation guidelines as well as information on tools and wiring.

2.Safety Instructions

WARNING: This chapter contains important safety and operating instructions. Read and keep this

manual for future reference.

1.Before using the unit, read all instructions and cautionary markings on the unit, the batteries and all

appropriate sections of this manual.

2.CAUTION --To reduce risk of injury, charge only deep-cycle lead acid type rechargeable batteries.

Other types of batteries may burst, causing personal injury and damage.

3.Do not disassemble the unit. Take it to a qualified service center when service or repair is required.

Incorrect re-assembly may result in a risk of electric shock or fire.

4.To reduce risk of electric shock, disconnect all wire before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

5.CAUTION – Only qualified personnel can install this device with battery.

6.NEVER charge a frozen battery.

7.For optimum operation of this inverter/charger, please follow required spec to select appropriate cable size.

It’s very important to correctly operate this inverter/charger.

8.Be very cautious when working with metal tools on or around batteries. A potential risk exists to drop a tool

to spark or short circuit batteries or other electrical parts and could cause an explosion.

9.Please strictly follow installation procedure when you want to disconnect AC or DC terminals. Please refer

to INSTALLATION section of this manual for the details.

10.Fuses are provided as over-current protection for the battery supply.

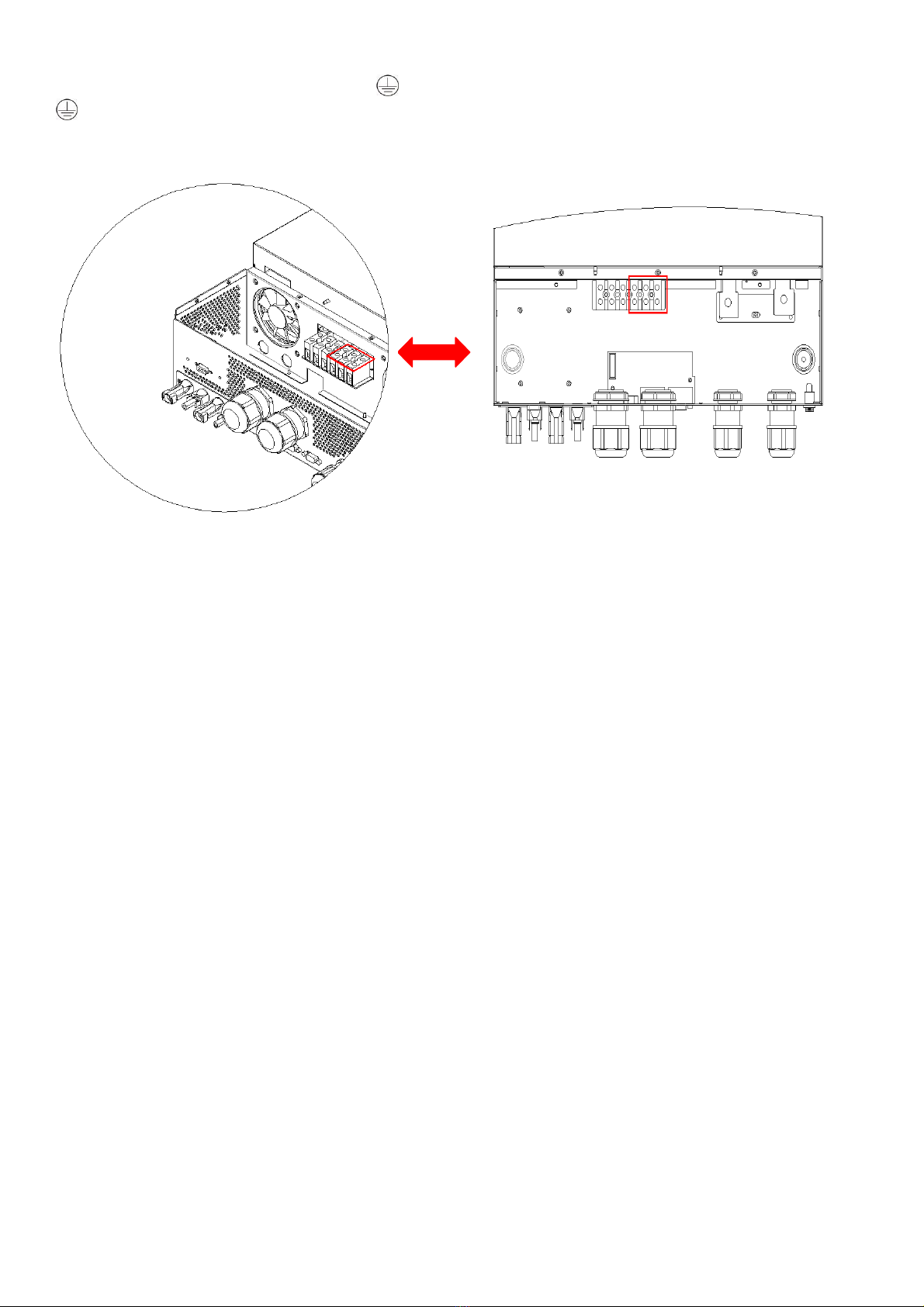

11.GROUNDING INSTRUCTIONS -This inverter/charger should be connected to a permanent grounded

wiring system. Be sure to comply with local requirements and regulation to install this inverter.

12. NEVER cause AC output and DC input short circuited. Do NOT connect to the mains when DC input short

circuits.

13.Warning!! Only qualified service persons are able to service this device. If errors still persist after following

troubleshooting table, please send this inverter/charger back to local dealer or service center for maintenance.

14. WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable:

single crystalline, poly crystalline with class A-rated and CIGS modules. To avoid any malfunction, do not

connect any PV modules with possible current leakage to the inverter. For example, grounded PV modules will

cause current leakage to the inverter. When using CIGS modules, please be sure NO grounding.

15. CAUTION: It’s required to use PV junction box with surge protection. Otherwise, it will cause damage on

inverter when lightning occurs on PV modules.

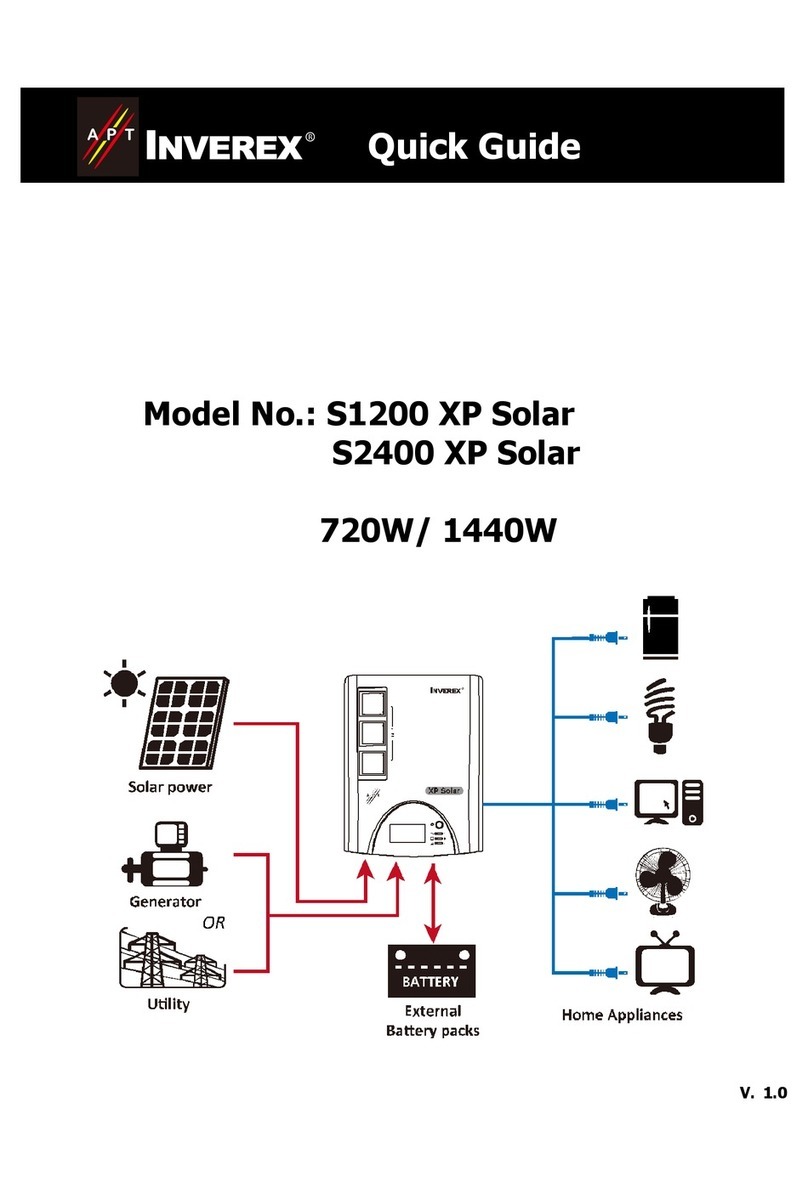

3. Introduction

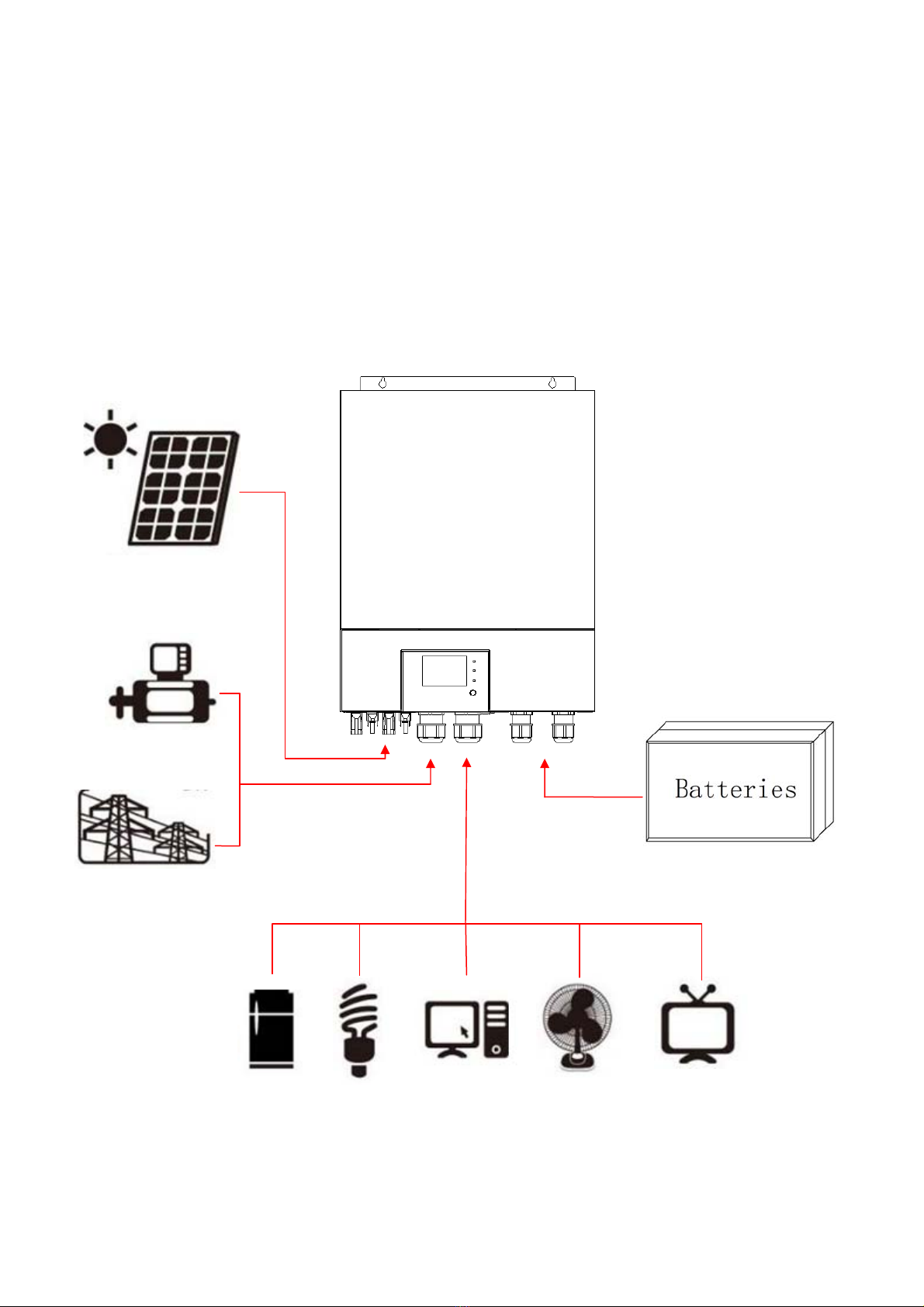

This is a multi-function inverter, combining functions of inverter, solar charger and battery charger to offer

uninterruptible power support in a single package. The comprehensive LCD display offers user-configurable

and easy-accessible button operations such as battery charging current, AC or solar charging priority, and

acceptable input voltage based on different applications.

3.1 Features

1.ON/Off grid inverter

2.Pure sine wave inverter

3. External WIFI devices (APP is required)

4. Communication ports with BMS (RS485, CAN)

5.Support the selection of wide and narrow range of AC input.

6.Configurable AC/Solar charger priority via LCD control panel

7.Configurable battery charging current based on applications via LCD control panel

8.Compatible to utility mains or generator power

9.Auto restart while AC is recovering

10.Overload / Over temperature / short circuit protection

11.Cold start function