Table of Contents

ABOUT THIS MANUAL ......................................................................................................................................1

Purpose............................................................................................................................................................1

Scope ...............................................................................................................................................................1

SAFETY INSTRUCTIONS...................................................................................................................................1

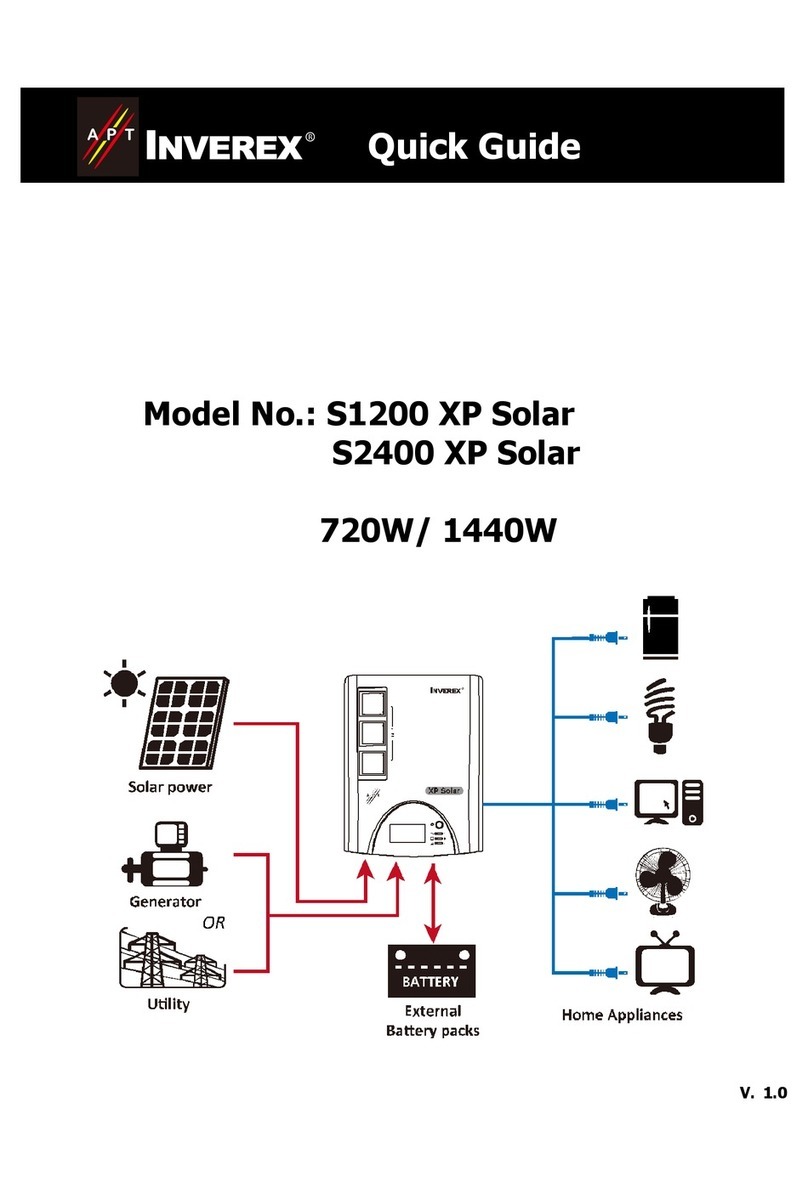

INTRODUCTION .................................................................................................................................................2

Features...........................................................................................................................................................2

Basic System Architecture ...............................................................................................................................2

Product Overview.............................................................................................................................................3

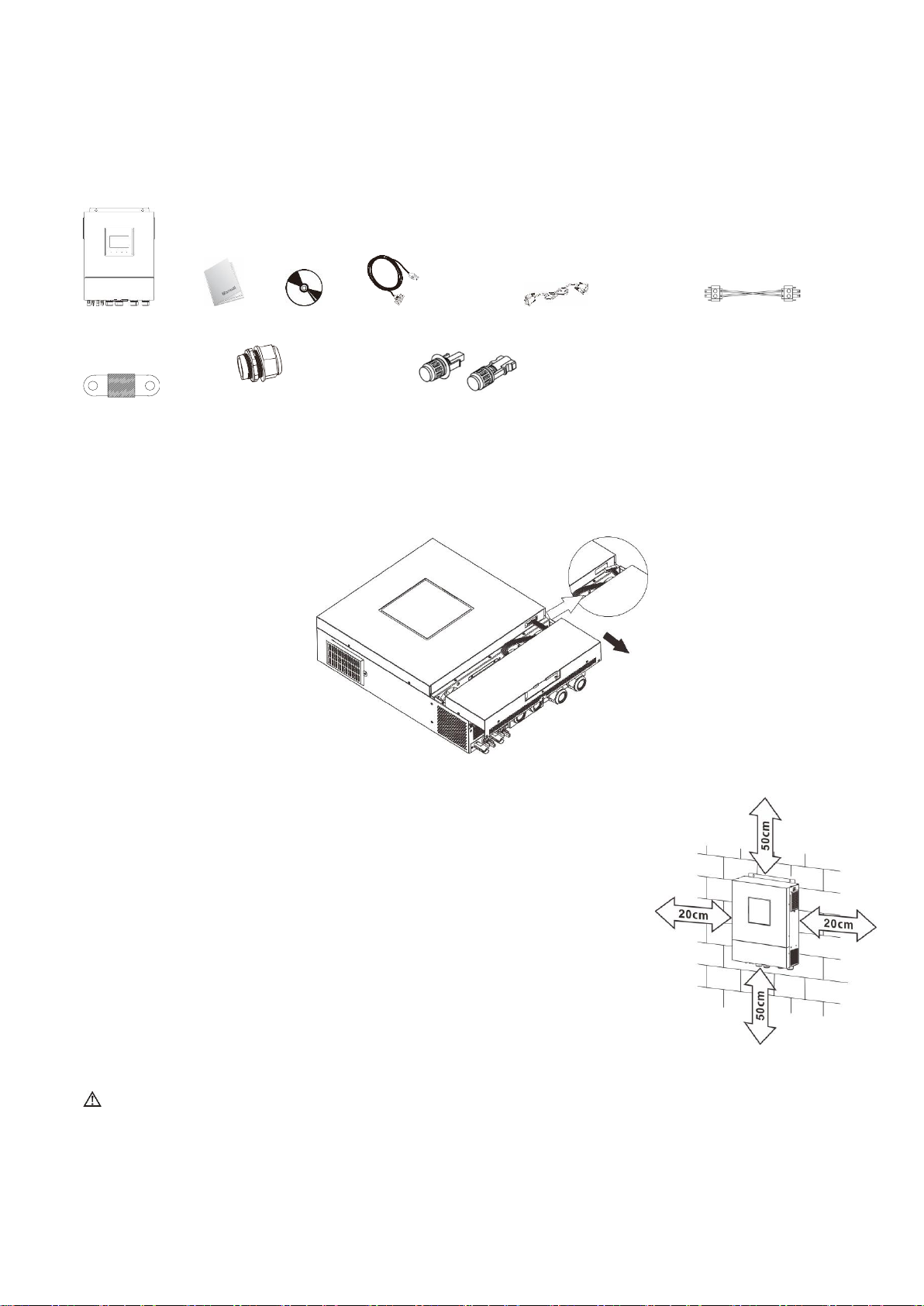

Unpacking and Inspection ...............................................................................................................................4

Preparation ......................................................................................................................................................4

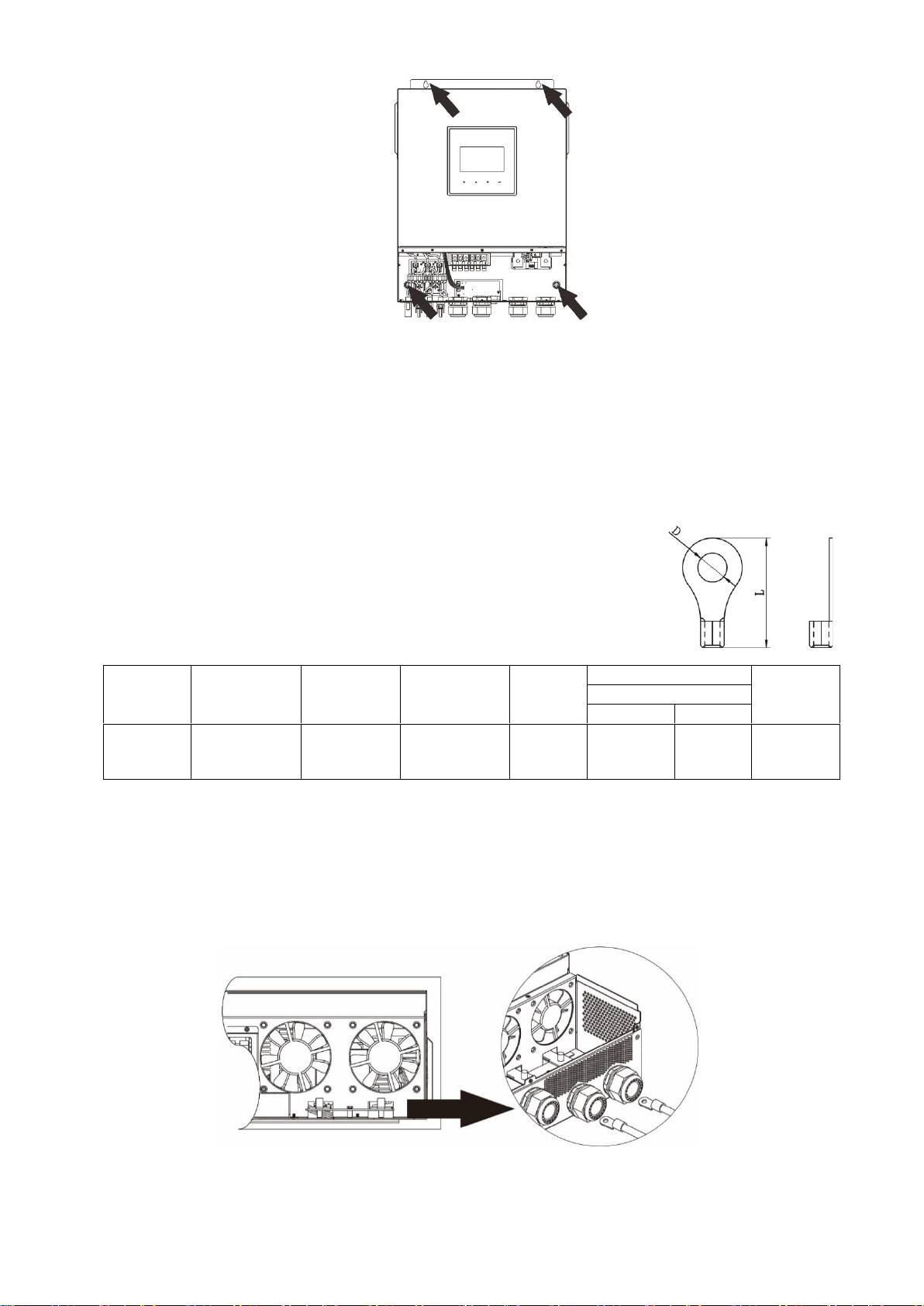

Mounting the Unit.............................................................................................................................................4

Battery Connection ..........................................................................................................................................5

AC Input/Output Connection ............................................................................................................................6

PV Connection .................................................................................................................................................7

Final Assembly...............................................................................................................................................10

Communication Connection...........................................................................................................................10

Dry Contact Signal .........................................................................................................................................12

BMS Communication .....................................................................................................................................12

OPERATION......................................................................................................................................................13

Power ON/OFF ..............................................................................................................................................13

Operation and Display Panel .........................................................................................................................13

LCD Display Icons .........................................................................................................................................14

LCD Setting....................................................................................................................................................17

LCD Display ...................................................................................................................................................32

Operating Mode Description ..........................................................................................................................38

Faults Reference Code..................................................................................................................................43

Warning Indicator ...........................................................................................................................................44

CLEARANCE AND MAINTENANCE FOR ANTI-DUST KIT............................................................................45

Overview ........................................................................................................................................................45

Clearance and Maintenance..........................................................................................................................45

BATTERY EQUALIZATION ..............................................................................................................................46

SPECIFICATIONS.............................................................................................................................................47

Table 1 Line Mode Specifications ...................................................................................................................47

Table 2 Inverter Mode Specifications .............................................................................................................48

Table 3 Charge Mode Specifications...............................................................................................................49

Table 4 General Specifications........................................................................................................................50

TROUBLE SHOOTING .....................................................................................................................................51

Appendix I: Parallel function ..........................................................................................................................52

Appendix II: BMS Communication Installation.............................................................................................64

Appendix III: The Wi-Fi Operation Guide in Remote Panel .........................................................................71