Copyright © 2016 Aqua Creek Products All Rights Reserved Revised 8/11/16

Basic Troubleshooting

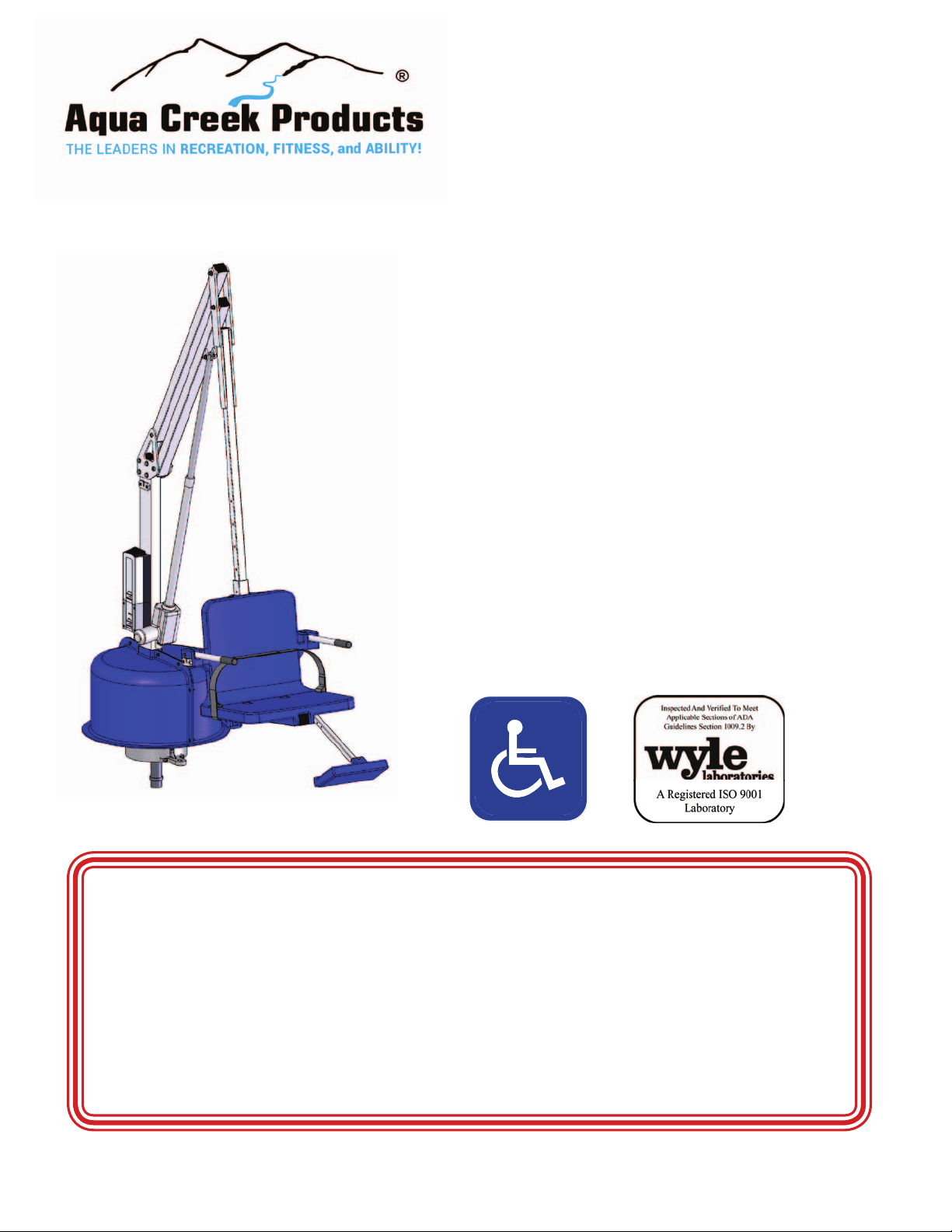

Problem: The lift won’t move.

Solution:

1. Make sure the battery is properly seated:

You should hear a click when

the battery is properly seated

on the control box or charger.

NOT Properly Attached:

Note: the white bracket is

in front of the silver clip,

which will not allow for

an electrical connection

Properly Attached:

Note: the white bracket

is behind the silver clip,

holding it securely to

allow for an electrical

connection

Check the ends of the cords for corrosion or

damage. The cord plugs should be recessed

into the outlet. You should feel them pop into

place when they are correctly inserted.

2. Make sure the cords are properly plugged in:

NOT Properly Inserted:

The cord plug is fl ush with

or sticking out of the outlet

Properly Inserted:

The cord plug is recessed

into the outlet

POP!

The Charger is ON

when the green

light is glowing

The Battery is

CHARGING when the

orange light is glowing

When the Battery is

charged the orange

light will stop glowing

4. Make sure the battery is fully charged:

3. Check the contact points:

Make sure the contact points of

the control box and the battery

are not damaged or corroded.

If there is corrosion clean with

Scotch-BriteTM pad. Put some

dielectric grease on the contact

points before reattaching the

battery.

Problem: The lift stopped moving over the water and is stuck.

Solution:

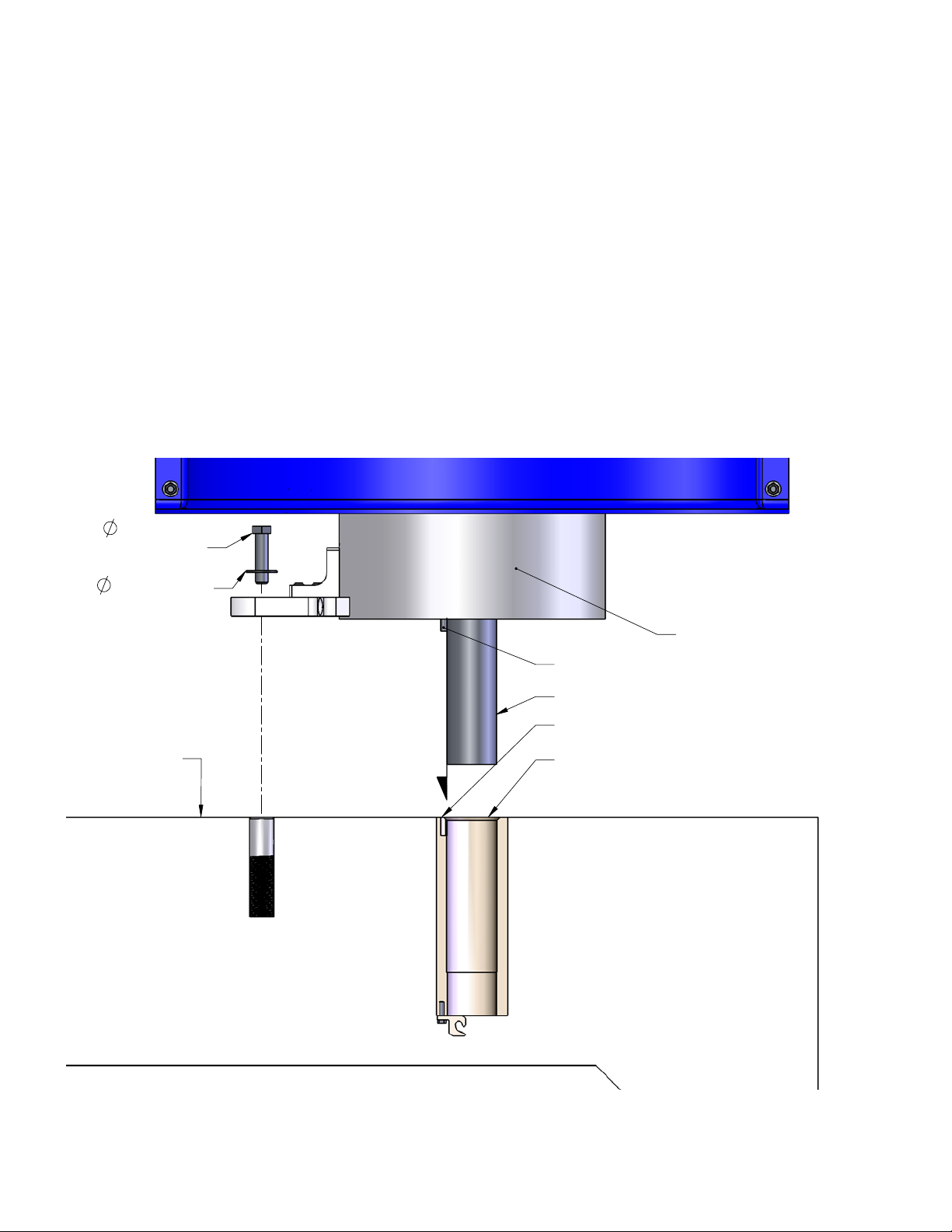

1. Press the emergency button

Use a pen or pencil tip and stick it into

the emergency button on the front of the

control box to retract the lift.

Note: the lift will not retract if the battery

is not fully charged or if the control box is

not working. The emergency button only

overrides the remote handset. 9