HC151+CST / HC151+PImA / HC200+CST

ENGLISH

3

INDEX

1. GENERAL RULES..................................................................................................................................... 4

1.1 SHIPPING AND TRANSPORTING THE PUMP ................................................................................. 4

1.2 INSTALLATION STANDARDS ........................................................................................................... 4

1.3 PROPER USE OF THE PUMP ........................................................................................................... 4

2. OPERATION .............................................................................................................................................. 6

2.1 OVERALL DIMENSIONS.................................................................................................................... 6

2.2 TECHNICAL FEATURES.................................................................................................................... 6

2.3 HYDRAULIC FEATURES ................................................................................................................... 7

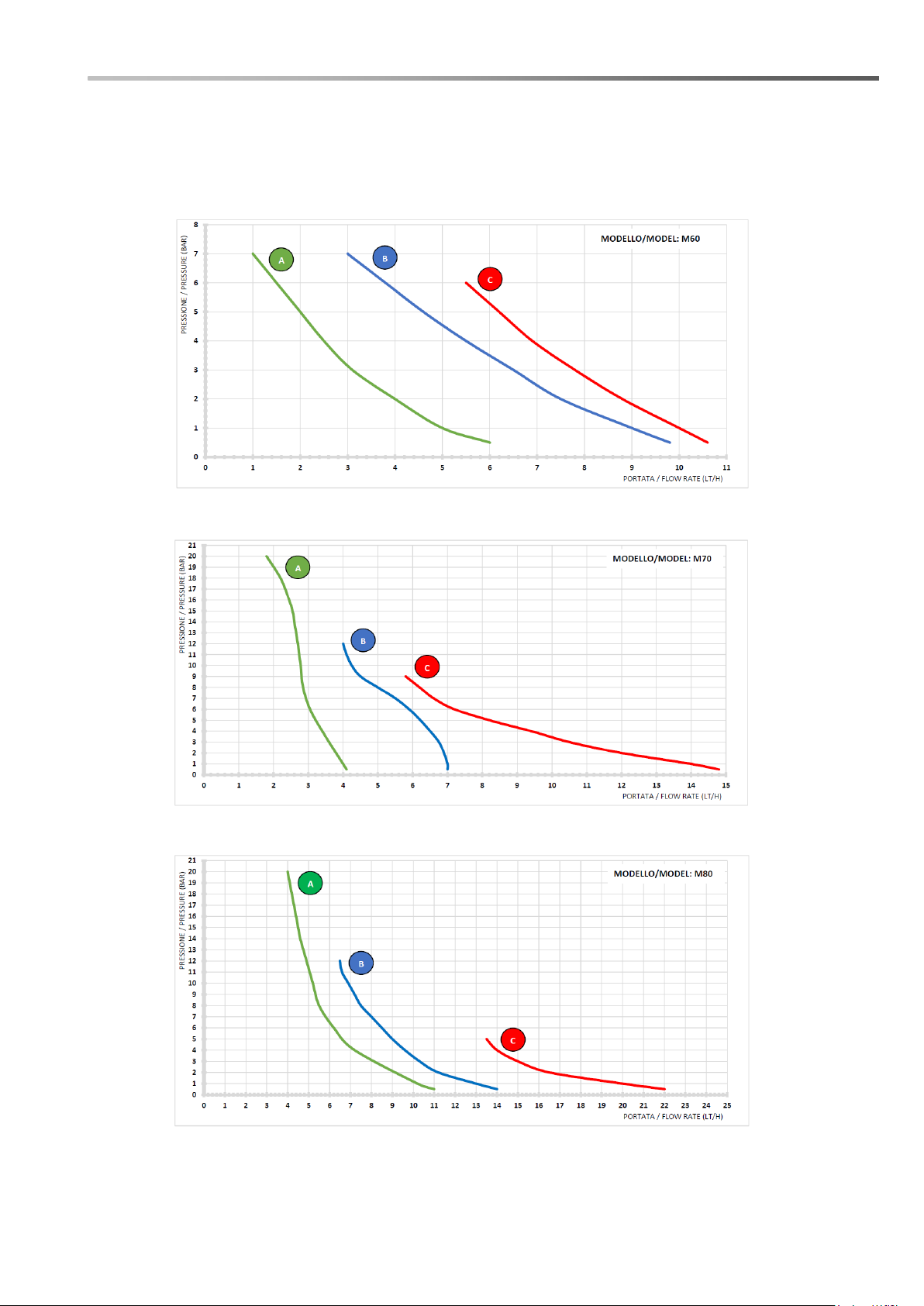

2.4 PERFORMANCE GRAPHS ................................................................................................................ 8

2.4.1 grafici relativi alle versioni a 230V ..................................... Errore. Il segnalibro non è definito.

2.5 CONTENT OF THE PACKAGE .......................................................................................................... 9

3. HC151+CST/HC200+CST....................................................................................................................... 10

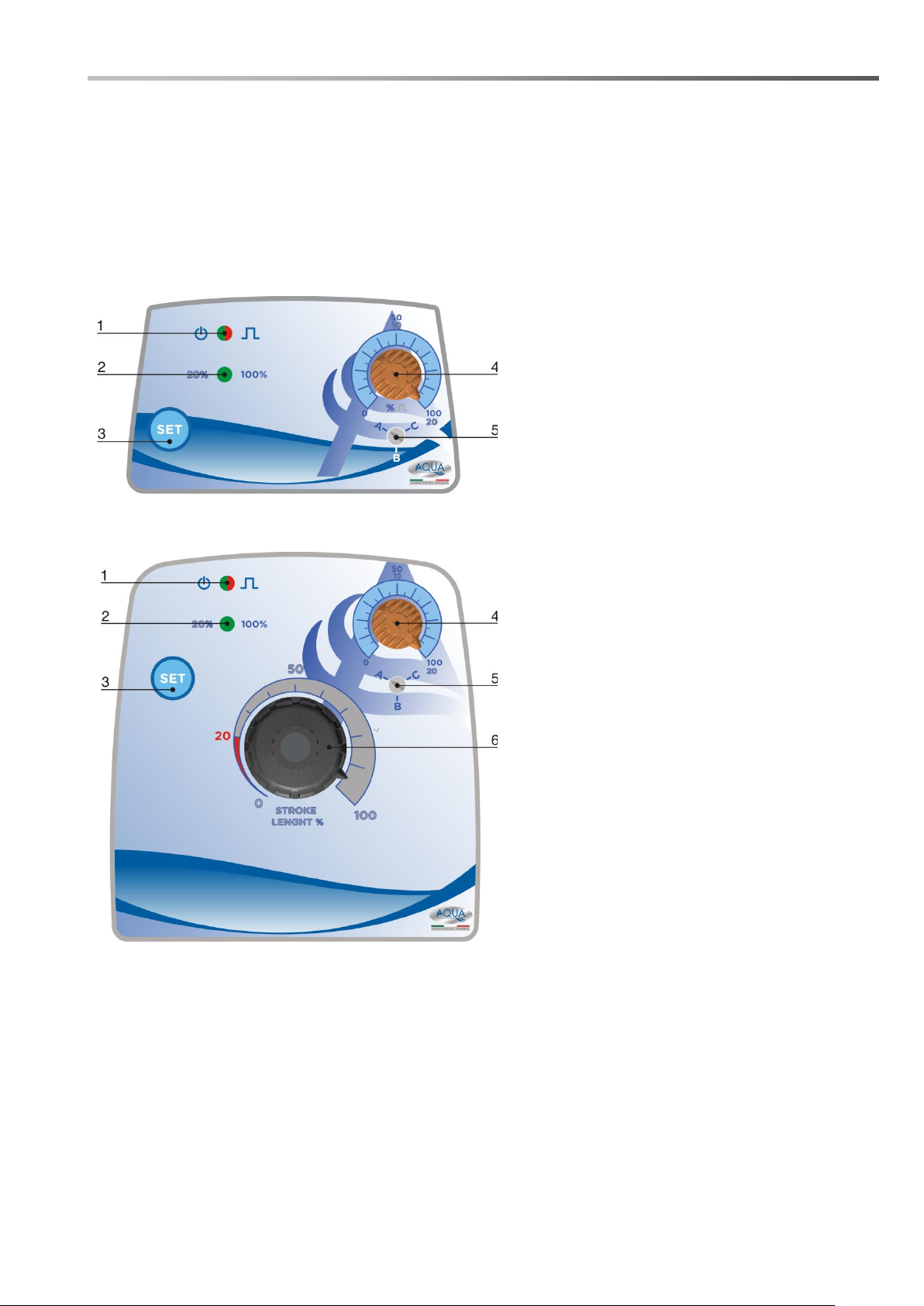

3.1 HC151+CST/HC200+CST PUMP CONTROLS ............................................................................... 10

3.2 HC151+CST/HC200+CST OPERATING MODE ............................................................................. 10

3.3 MODIFICATION OF PUMP PERFORMANCE ................................................................................. 11

4. HC151+PImA........................................................................................................................................... 12

4.1 HC151+PImA PUMP CONTROLS ................................................................................................... 12

4.2 MODIFICATION OF PUMP PERFORMANCE ................................................................................. 12

4.3 HC151+PImA OPERATING MODE.................................................................................................. 13

4.5 HOW TO CHOOSE THE PERFORMANCES OF A PUMP .............................................................. 14

4.6 HOW TO CALCULATE THE MULTIPLICATION VALUE (1xN) ....................................................... 14

4.7 HOW TO CALCULATE THE DIVISION VALUE (1:N) ...................................................................... 14

5. DOSING PUMPS INSTALLATION RULES............................................................................................. 15

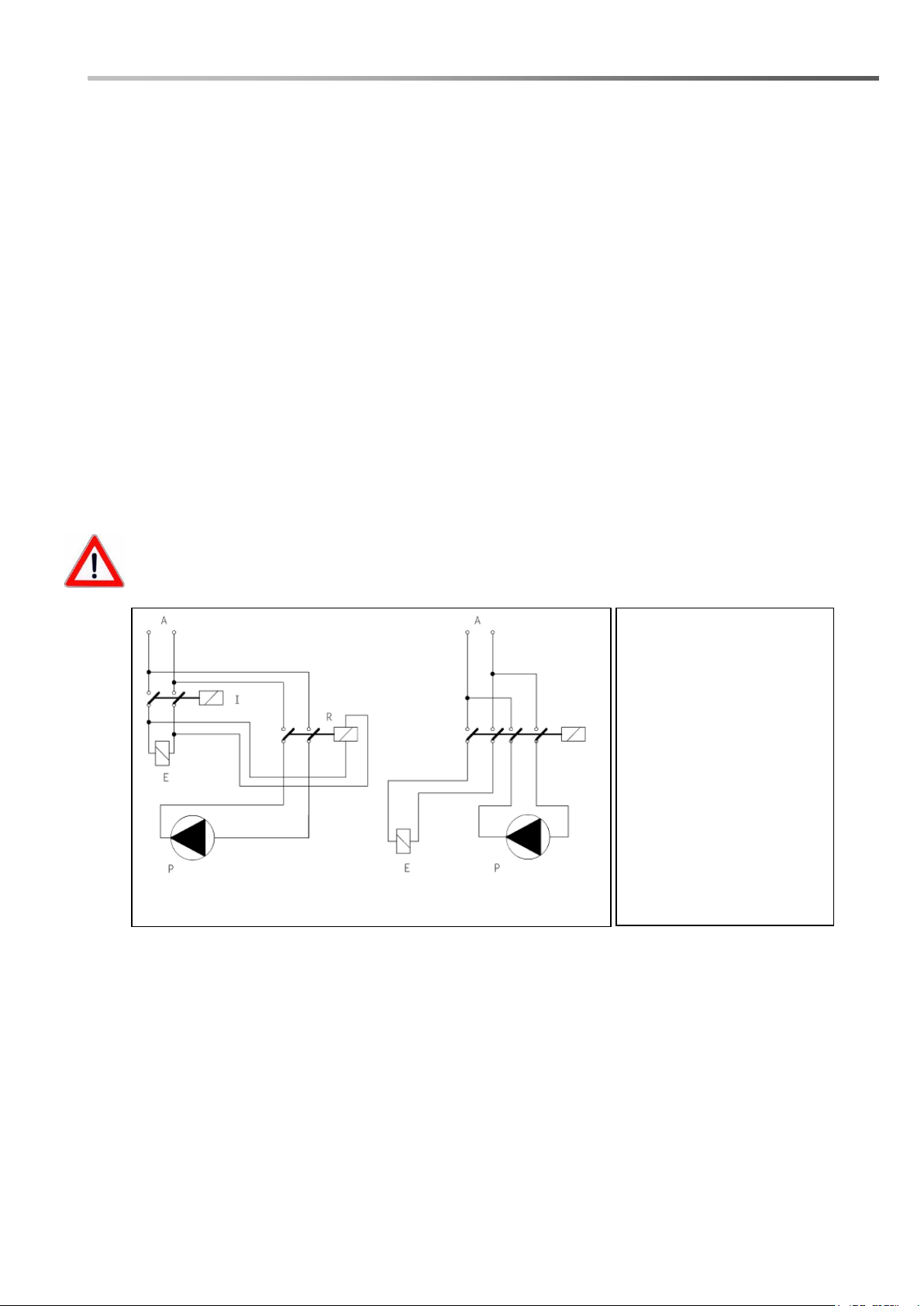

6. ELECTRICAL CONNECTIONS ............................................................................................................... 16

6.1 HC151+ PImA model pump .............................................................................................................. 16

5.1 CHOICE OF THE PUMP VOLTAGE................................................................................................. 16

7. TROUBLESHOOTING ............................................................................................................................. 17

7.1 PROBLEM –CAUSE –SOLUTION.................................................................................................. 17

8. CLEANING AND MAINTENANCE .......................................................................................................... 17

8.1 CLEANING THE PUMP .................................................................................................................... 17

8.2 PUMP MAINTENANCE..................................................................................................................... 18

9. WARRANTY............................................................................................................................................. 18

EXPLODED VIEWS ........................................................................................................................................ 20