Subject to change · UM 045_14264401 · 0916 · EN

Page 2 www.argo-hytos.com

Contents

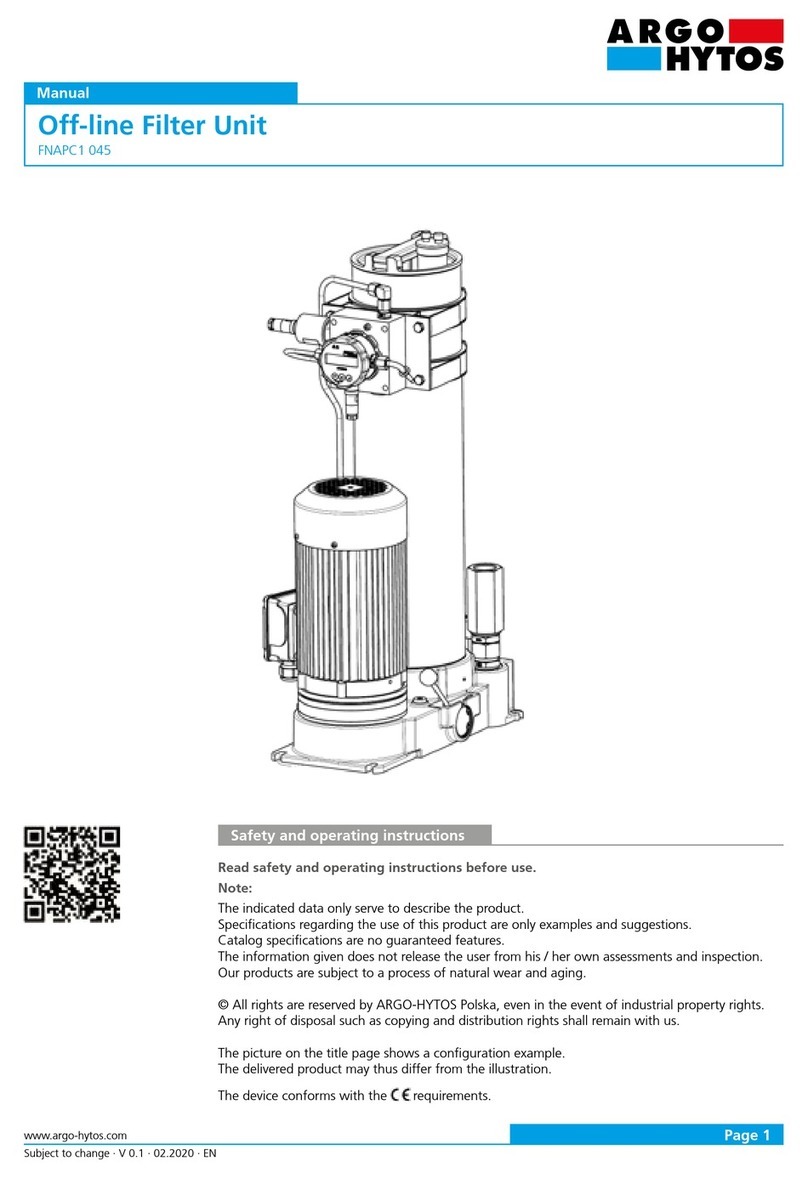

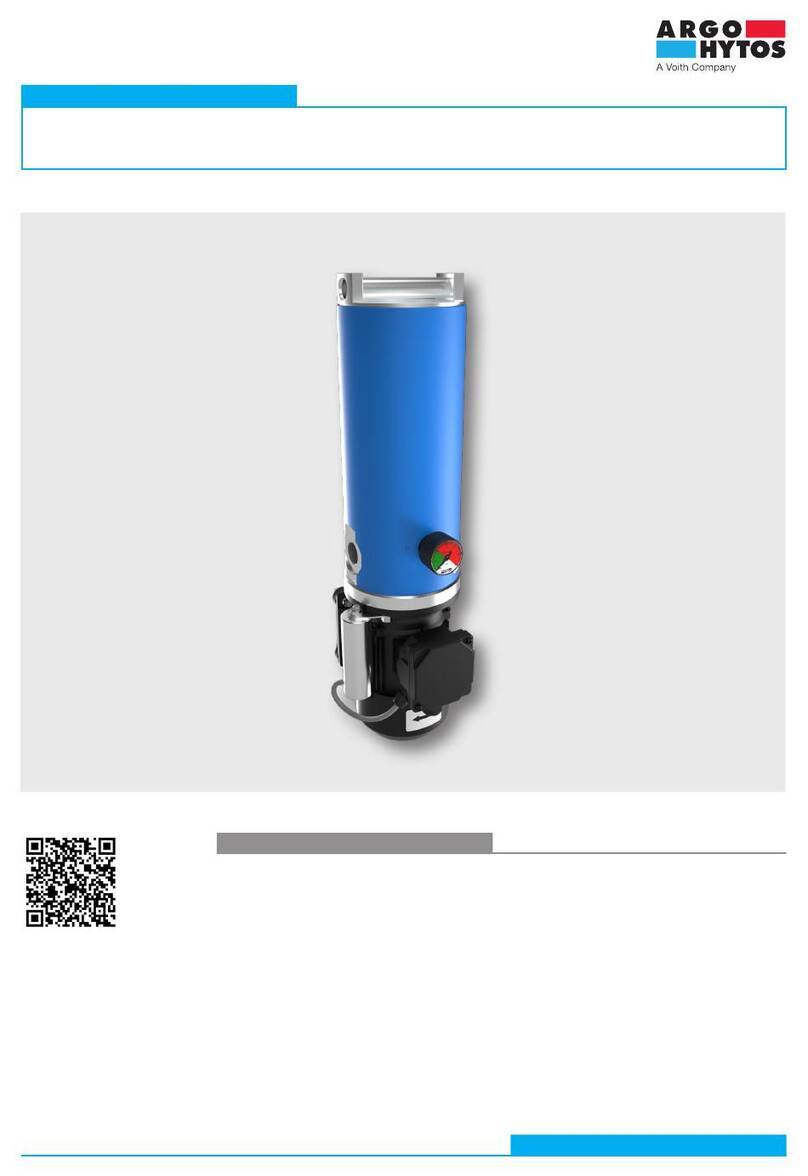

Filter Unit Ecoline UM 045 / UMP 045

Contents ............................................................................................................................................................................. 2

1. Intended purpose ............................................................................................................................................................. 4

1.1 Scope of use........................................................................................................................................................................ 4

1.2 With UMP 045 .................................................................................................................................................................... 4

1.3 Keeping to the permitted operating conditions.................................................................................................................... 4

1.4 Reasonably foreseeable misuse ............................................................................................................................................ 4

2. Safety notes and commissioning .................................................................................................................................... 5

2.1 General references............................................................................................................................................................... 5

2.2 Meaning of operating instruction symbols ........................................................................................................................... 5

2.3 Required staff qualification .................................................................................................................................................. 5

2.4 Contents of delivery UM 045............................................................................................................................................... 5

2.5 Contents of delivery UMP 045 ............................................................................................................................................. 5

2.6 Do not use or store the device ............................................................................................................................................. 6

2.7 Transport............................................................................................................................................................................. 6

2.8 Mains connection ................................................................................................................................................................ 6

2.9 Essential points to note before commissioning the filter unit................................................................................................ 6

2.10 With UMP 045: Installation of the particle counter PODS pro............................................................................................... 7

2.11 On start up check ................................................................................................................................................................ 8

2.12 If there is an unexpected power failure, it is essential to note these points ........................................................................... 8

3. Dimensions of the device................................................................................................................................................. 9

4. How to operate the filter unit....................................................................................................................................... 10

4.1 Filtering hydraulic fluids in the by-pass flow (note safety instructions) ................................................................................ 10

4.2 Filtering of hydraulic fluids while filling machinery and plant.............................................................................................. 11

4.3 Pumping of hydraulic fluids (e. g. waste oil, filter is by passed)........................................................................................... 11

4.4 To achieve the maximum cleaning performance................................................................................................................. 11

5. Technical data ................................................................................................................................................................. 12

5.1 Device data ....................................................................................................................................................................... 12

6. Operating conditions ..................................................................................................................................................... 13

7. Shutdown and disposal ................................................................................................................................................. 14

8. Maintaining the filter unit ............................................................................................................................................. 15

8.1 Maintenance survey........................................................................................................................................................... 15

8.2 Replacing the filter element ............................................................................................................................................... 15

8.3 Checking / changing of the suction strainer (protective strainer for the pump) ................................................................... 16

9. Faultfinding / troubleshooting...................................................................................................................................... 18

10. Appendix......................................................................................................................................................................... 20

10.1 EU- Declaration of Conformity........................................................................................................................................... 20