Subject to change · UMPC 045_31168300 · 0717 · EN

Page 2 www.argo-hytos.com

Content

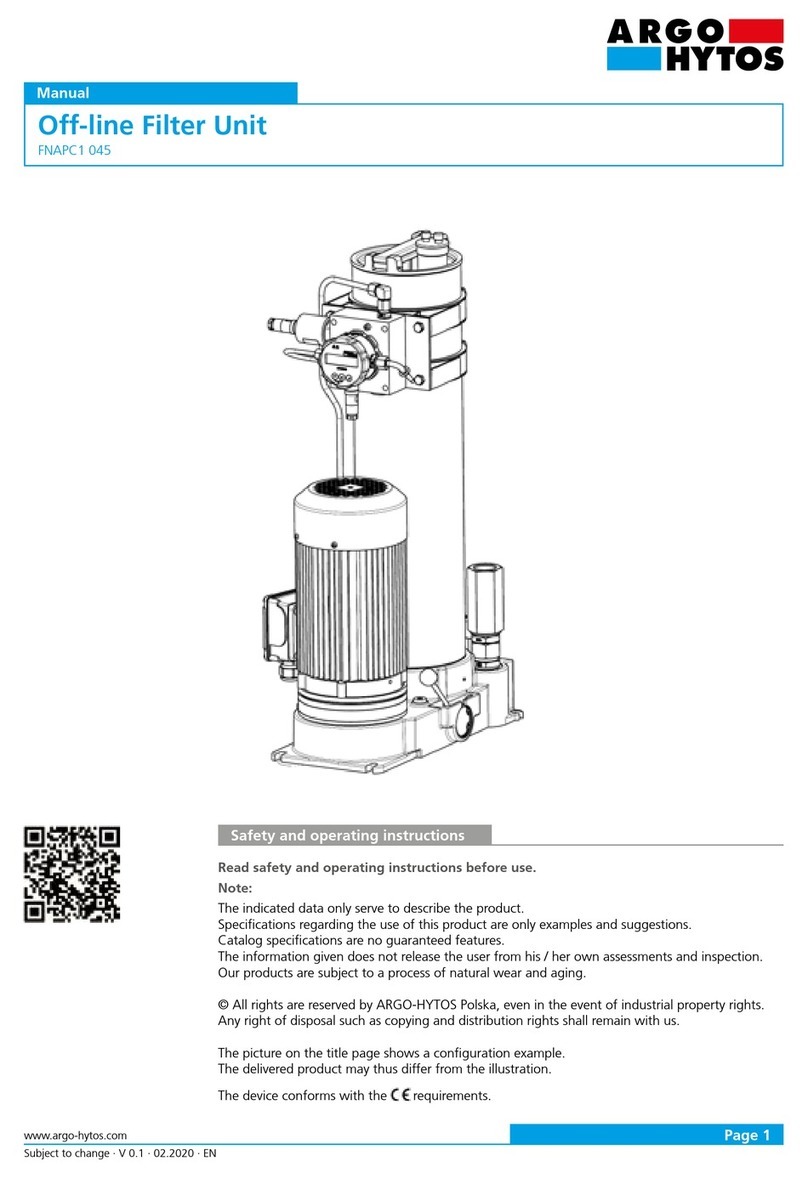

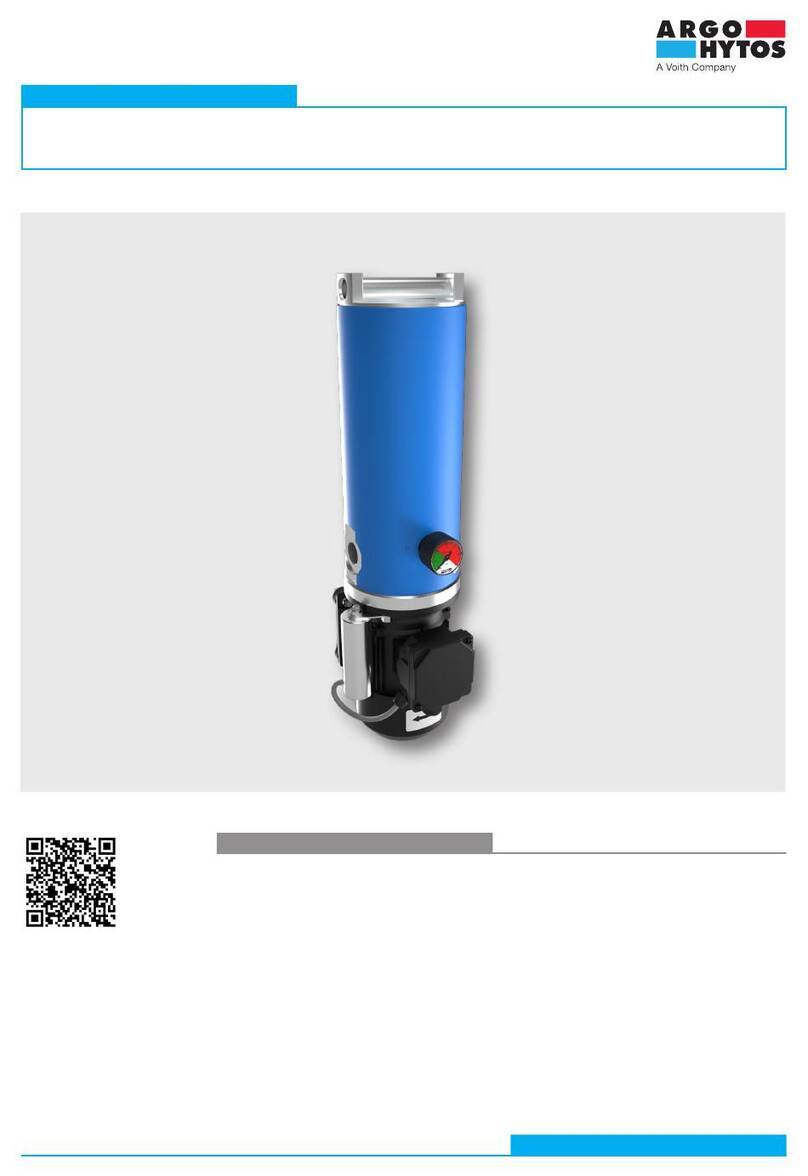

Filter and Recirculating Pump Unit UMPC 045

Content.......................................................................................................................................................................... 2

1. About this documentation........................................................................................................................................... 4

1.1 Applicability of this documentation ................................................................................................................................. 4

1.2 Required and supplementary documentation .................................................................................................................. 4

1.3 Presentation of information ............................................................................................................................................ 4

1.3.1 Safety instructions .......................................................................................................................................................... 4

1.3.2 Symbols .......................................................................................................................................................................... 5

1.3.3 Terms ............................................................................................................................................................................. 5

1.3.4 Abbreviations .................................................................................................................................................................. 5

2. Safety instructions........................................................................................................................................................ 6

2.1 About this chapter .......................................................................................................................................................... 6

2.2 Intended use .................................................................................................................................................................. 6

2.3 Improper use .................................................................................................................................................................. 6

2.4 Reasonable foreseeable misuse ....................................................................................................................................... 6

2.5 Qualification of personnel ............................................................................................................................................... 6

2.6 General safety instructions .............................................................................................................................................. 7

2.7 Product and technology related safety instructions .......................................................................................................... 7

3. General instructions ..................................................................................................................................................... 8

4. Scope of delivery.......................................................................................................................................................... 9

5. About this product ..................................................................................................................................................... 10

5.1 Component overview ................................................................................................................................................... 10

5.2 Controls ....................................................................................................................................................................... 13

5.3 Identification of the product .......................................................................................................................................... 14

6. Transport and storage................................................................................................................................................ 15

6.1 Transport ...................................................................................................................................................................... 15

6.2 Storage ......................................................................................................................................................................... 15

7. Assembly..................................................................................................................................................................... 16

8. Commissioning ........................................................................................................................................................... 17

8.1 After switching on ........................................................................................................................................................ 17

8.2 In case of power failure ................................................................................................................................................ 17

8.3 Venting ......................................................................................................................................................................... 17

9. Service ......................................................................................................................................................................... 18

9.1 Switching on the device ................................................................................................................................................ 18

9.2. Data collection ............................................................................................................................................................. 20

9.3 Menu structure LubMon Visu ........................................................................................................................................ 21

10. Operation.................................................................................................................................................................... 22

10.1 Filtering of hydraulic fluids when refilling ...................................................................................................................... 23

10.2 Filtering of liquids in the bypass flow ............................................................................................................................ 24

10.3 Pumping of hydraulic fluids (e.g. waste oil, filter is bypassed) ........................................................................................ 25

10.4 Monitoring the oil cleanliness when filling machines and systems ................................................................................. 26

10.5 Monitoring the oil cleanliness when cleaning machines and systems in the bypass flow ................................................ 27

10.6 Monitoring modes ........................................................................................................................................................ 28

10.6.1 Continuous measurement without automatic shutdown (Mode 1) ................................................................................ 28

10.6.2 Measurement with cleanliness class specific shutdown (Mode 2).................................................................................... 28