7

3. Frameset Parts, SKUs and descriptions

No. Name Assembled on A18 SKU# Qty

Parts already assembled

Parts

1 Nitrogen Disc Frame - - 1

2 Nitrogen Disc Fork - FK.NITD.340A 1

FK.NITD.340B

3 Nitrogen Disc Seat Post Assembly - SP.NIT_D.286A 1

10 BB Cover (incl. screw) Frame 38260 1

11 Seat Clamp Base (incl. screw) Frame 80478 1

12 Seat Clamp Wedge (incl. screw) Frame 80477 1

13 Di2 Cable Grommet Frame 38888 1

16 Headset (Token or FSA ACR) Fork Token: 81300 / FSA: 81299 1

20 Internal Di2 Battery Support Seat Post 38757 1 Set

24 Direct Mount Rear Derailleur Hanger Frame 80832 1

25 DT Swiss RWS Thru-axle FRONT 12 x 119mm Fork 80812 1

26 DT Swiss RWS Thru-axle REAR 12 x 161mm with handle Frame 80813 1

28 Oblong Cable Guide Frame 80551 1

32 Foam liner for housing Frame 80811 2

33 LONG GROMMET MECH frame 80985 1

34 Long plug frame 80804 1

35 Long Grommet DI2 frame 80805 1

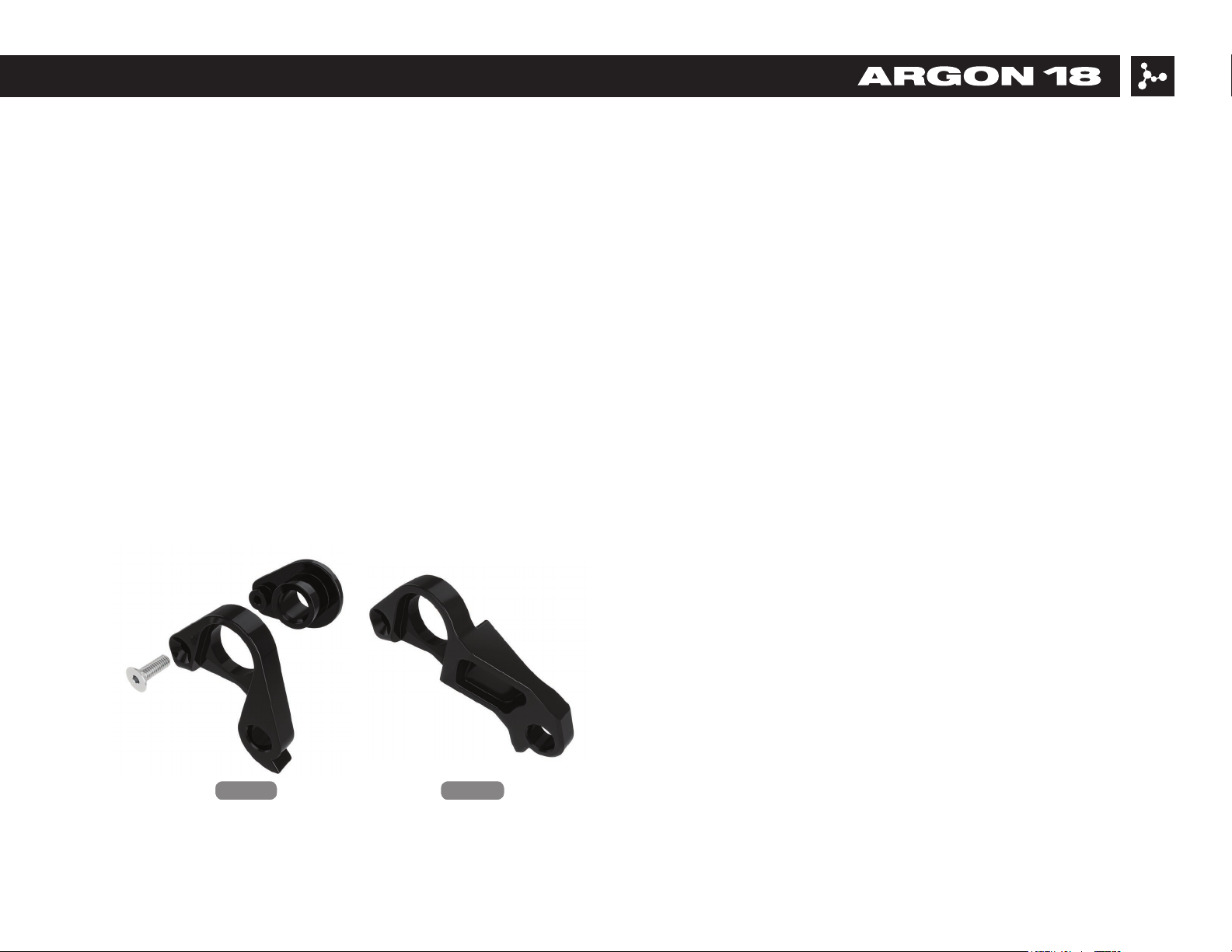

8 Rear Derailleur Hanger (incl. dropout, screw) Frame 80802 1

6 Front Derailleur Hanger (incl. screws) Frame 38882 1

9 BB Cable Guide (incl. screw) Frame 38885 1

7 Bottle Cage Screws Frame 38884 4

*Except for the frame itself, which is not sold as a spare part, all parts can be ordered by referring to their respective SKU number.