14.148.- / A414D en / Software 1.30 14.10.2003 7

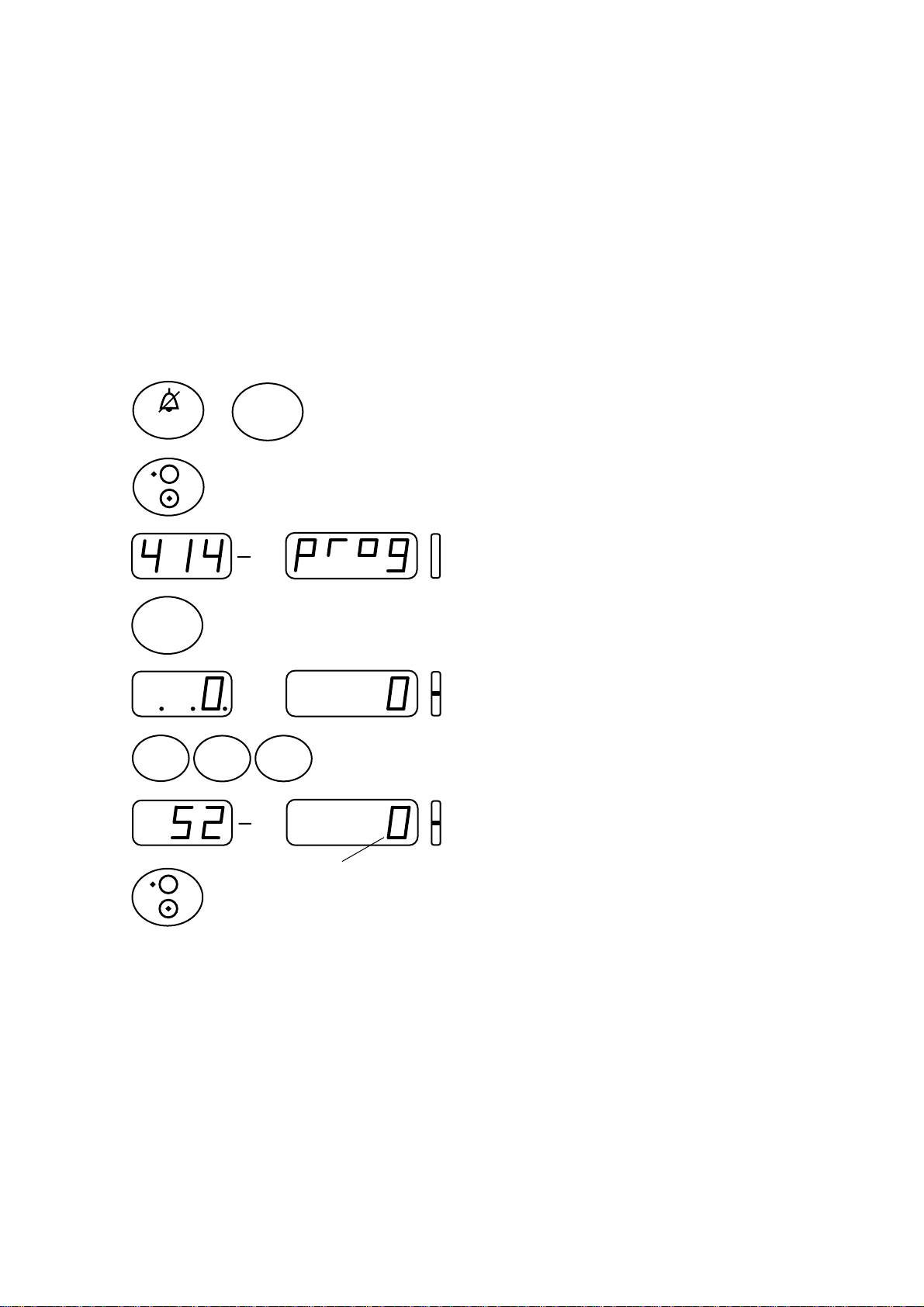

1.5 List of the interrogation- and configuration functions:

CAUTION! Before you make a new configuration or replace an EPROM or the mainboard make a note of

the programmed values. Afterwards you can re-enter the old not writeprotected values.

Address Write Default Function

(#) prot. Value

00= No PIN code active

11= Yes Run indication by running decimal point

20= No Key "ON/OFF" only at STOP valid

30= No Rate change only at STOP valid

40= No Key "STOP" delayed (time at #361)

50= No 2nd entry of rate (#3=1), rate calculation disabled.

60= No Static alarm (staff alerting system)

70= No Display elapsed time in run mode (#8=0) ****

80= No Select remaining time (#7=1)

91= Yes Alternative time input (10h, 1h, 1/4h)

10 0 = No Operation without drop detector

11 1 = Yes Recall "ml/h" (rate) at next power on

12 0 = No Recall "ml total" (end volume) at next power on

13 0 = No Recall "ml inf." (volume inf.) at next power on

14 0 = No SBS Step By Step function

15 0 = No Display VTBI (Volume To Be Infused)

16 0 = No Display "SEt -X-"’ if only 1 set enabled

17 1 = Yes KVO (KOR), mode see #60

18 0 = No Drop alarm only if bottle is empty (#10=0)

19 1 = Yes Buzzer at start

20 0 = No Menu "CLr" (clear "ml inf.") (#15=0) ****

21 0 = No Menu "uOP" (Micro operation) ****

22 0 = No Menu "trA" (transport) (#10=0 and #18=0) ****

23 1 = Yes Menu "PrL" (pressure alarm limit) ****

24 1 = Yes Menu "CAP" (battery capacity) ****

25 0 = No Menu "SEt Fill" ****

26 0 = No Menu "InF" ("ml inf." since last power on) ****

27 0 = No Menu "dLo" (data-lock) ****

28 0 = No Menu "Stb" (stand-by) ****

29 0 = No Menu "MEd" (medication number) ****

30 0 = No Menu "tM " (timer alarm) ****

31 0 = No

32 0 = No Menu "boL" (release bolus) ****

33 0 = No Menu "boLr" (bolus rate) (#32=1) ****

34 0 = No Menu "tot" (bolus total) (#32=1) ****

35 0 = No

36 0 = No

37 0 = No

38 0 = No Bolus application automatic (#32=1 and #34=1)

39 0 = No

40 0 = No Demo mode (all menus enabled) ****

41 0 = No Clear "ml/h" after infusion completed

42 0 = No Clear "ml total" after infusion completed (#41=1)

43 0 = No Air volume accumulated (1ml over 0.5 hrs)

44 1 = Yes Automatic pressure release after occlusion

45 1 = Yes Pressure display 20/40/60/80/100% (Bargraph ON)

46 0 = No Bargraph with indicator (25% steps, #45=1)

47 0 = No Standby- and battery prealarm low volume

48 1 = Yes Flashing numeric display at alarm

49 0 = No Alarm acknowledge only with key "MODE"