1

TABLE OF CONTENTS

1. GENERAL INFORMATION...............2

1.1 GUARANTEE .........................................2

1.2 SYSTEM CONTENTS ...............................2

1.3 SYSTEM INSTRUCTION BOOKS..................2

1.4 SOLARCOMFORT .................................3

1.5 LIFESTYLE ............................................3

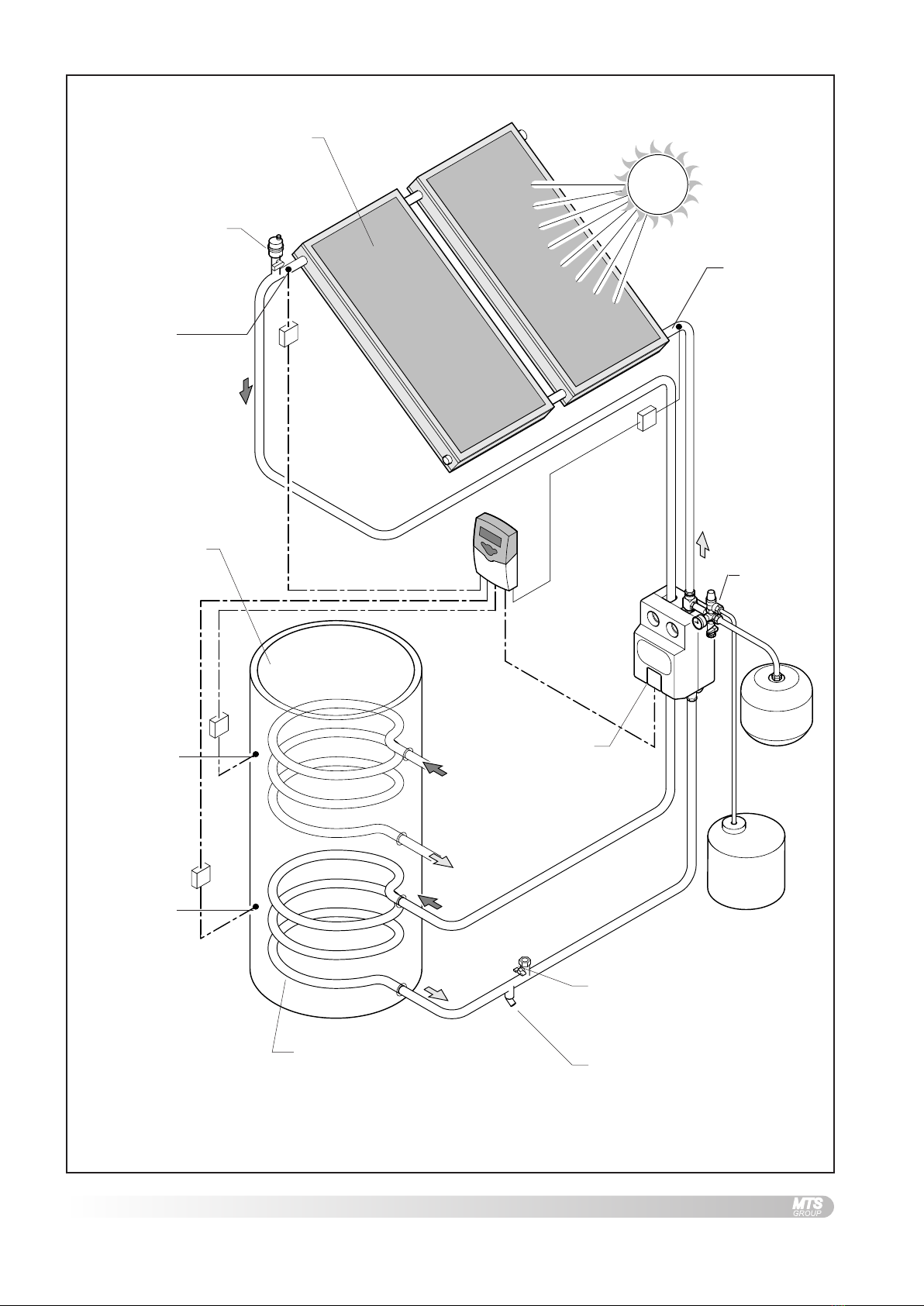

1.6 HOW THE SYSTEM WORKS......................3

2. SAFETY............................................5

3. TECHNICAL DATA............................6

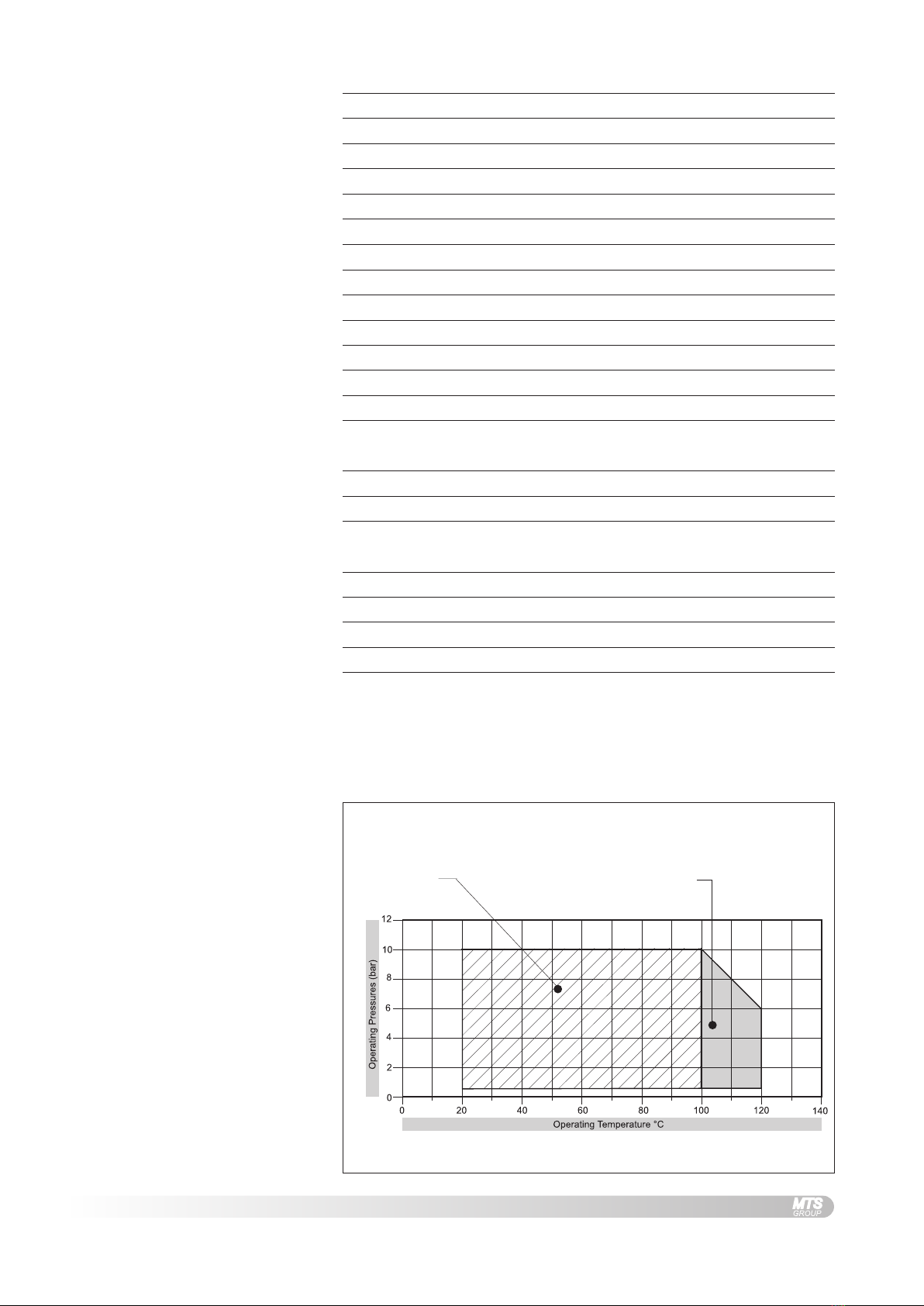

3.1 TEMPERATURE/PRESSURE .......................6

3.2 COMPONENT LIST FOR 2 COLLECTOR SYSTEM

7

3.3 COMPONENT LIST FOR 3 COLLECTOR SYSTEM

8

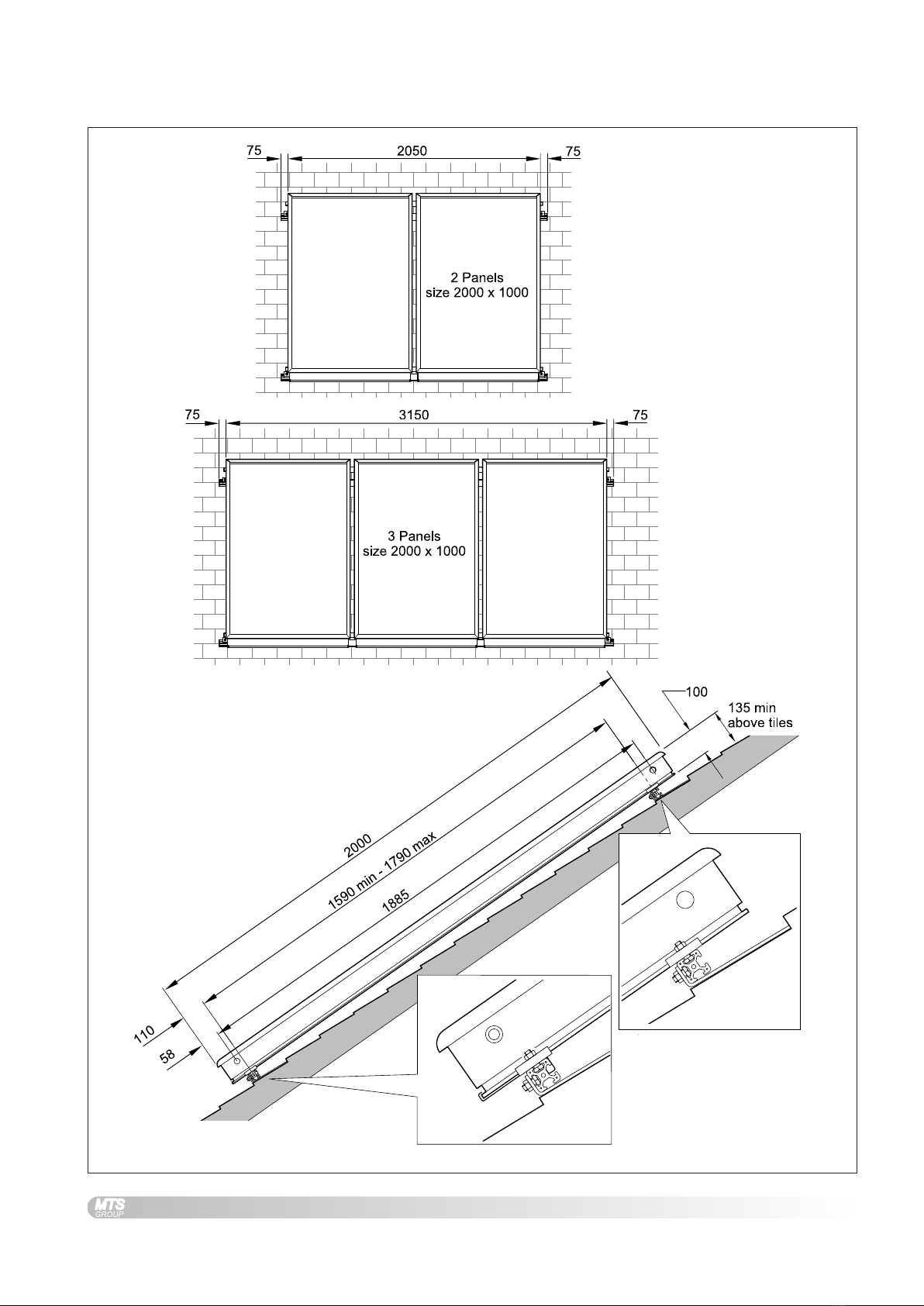

3.4 COLLECTOR DIMENSIONS ........................9

3.5 FIXING STRAPS DIMENSIONS .................10

4. REGULATIONS & STANDARDS.....11

4.1 WATER REGULATIONS ..........................11

4.2 BUILDING REGULATIONS........................11

4.3 GENERAL GUIDANCE ............................11

4.4 BRITISH & EUROPEAN STANDARDS .........12

4.5 UK REGULATIONS (WATER HEATING) .....12

4.6 UK REGULATIONS (CONSTRUCTION) .......12

4.7 EU DIRECTIVES ..................................13

4.8 OTHER PUBLICATIONS ..........................13

4.9 ELECTRICAL CONNECTION .....................13

4.10 THERMAL INSULATION ...........................13

5. INSTALLATION ...............................14

5.1 TOWN & COUNTRY PLANNING ...............14

5.2 HOUSE INSURANCE ..............................14

5.3 RISK ASSESSMENT ..............................14

5.4 ROOF CONDITION ................................14

5.5 POSITIONING COLLECTORS ....................14

5.6 CONSIDERATIONS FOR POSITIONING

COLLECTORS ......................................14

5.7 COLLECTOR INCLINATION .......................15

5.8 PIPEWORK & FITTINGS .........................15

5.9 INSULATION.........................................15

5.10 SIZING OF PIPES .................................15

5.11 PIPEWORK..........................................16

5.12 COLLECTOR COUPLINGS .......................16

5.13 COLLECTOR CONFIGURATIONS ...............17

5.14 TWO COLLECTOR SCHEMATIC ................18

5.15 THREE COLLECTOR SCHEMATIC .............19

5.16 FIXING STRAPS ...................................20

5.17 ROOF TYPES ......................................21

5.18 COLLECTOR FIXINGS ............................22

5.19 COLLECTOR FITTING PROCEDURE...........23

5.20 PLUMBING CONNECTIONS......................28

6. COMMISSIONING & SERVICING..28

7. FLAT ROOF/GROUND MOUNTING

KIT ..................................................29

7.1 COMPONENT LIST ................................29

7.2 ANGLE OF INCLINATION .........................29

7.3 COLLECTOR ORIENTATION .....................30

7.4 DIMENSIONS .......................................30

7.5 FLAT ROOF CONDITION ........................30

7.6 GROUND PREPARATION.........................31

7.7 ASSEMBLY ..........................................31