Simply platform lifts

20110609 © ARITCO 3

1 Feature list

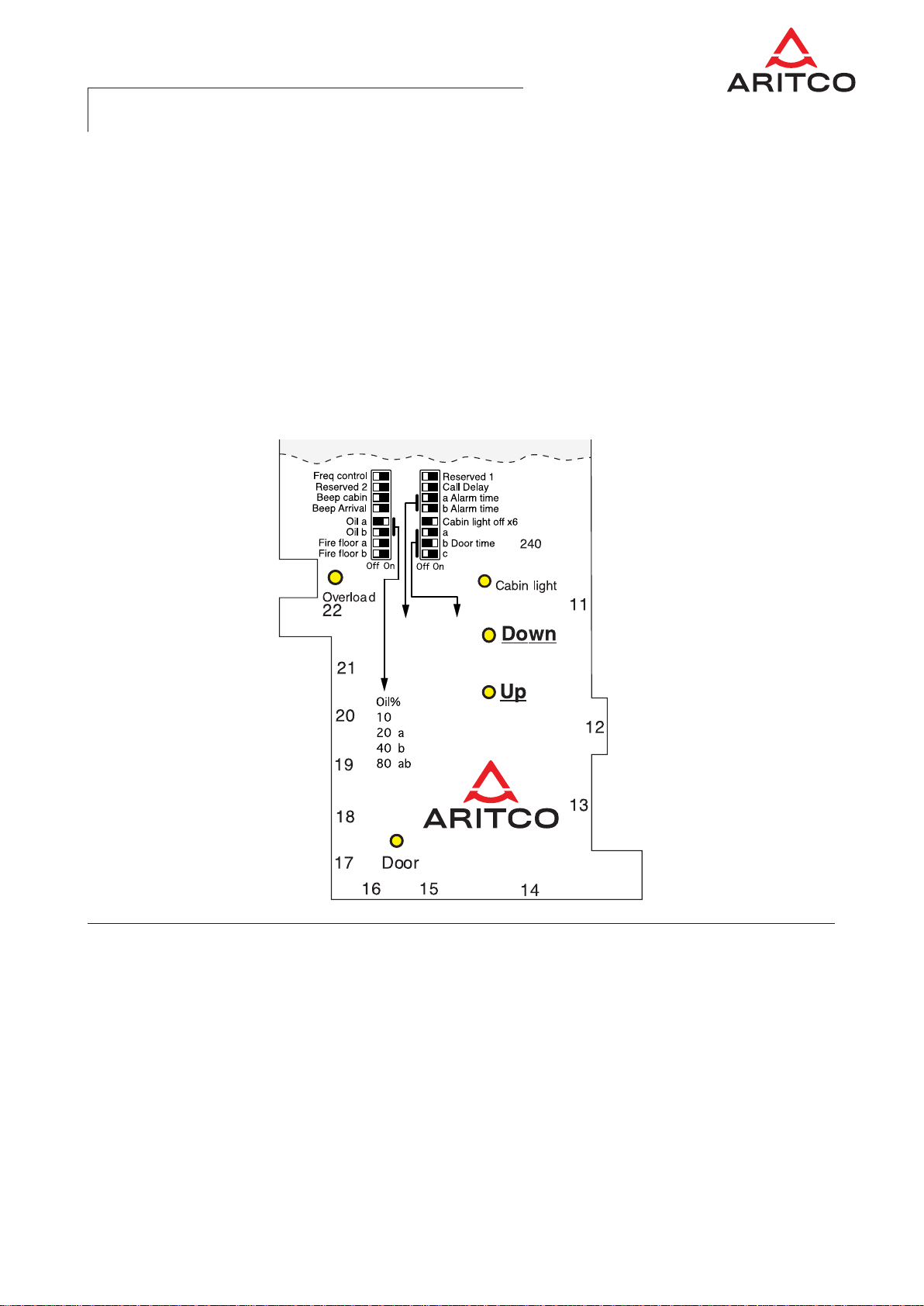

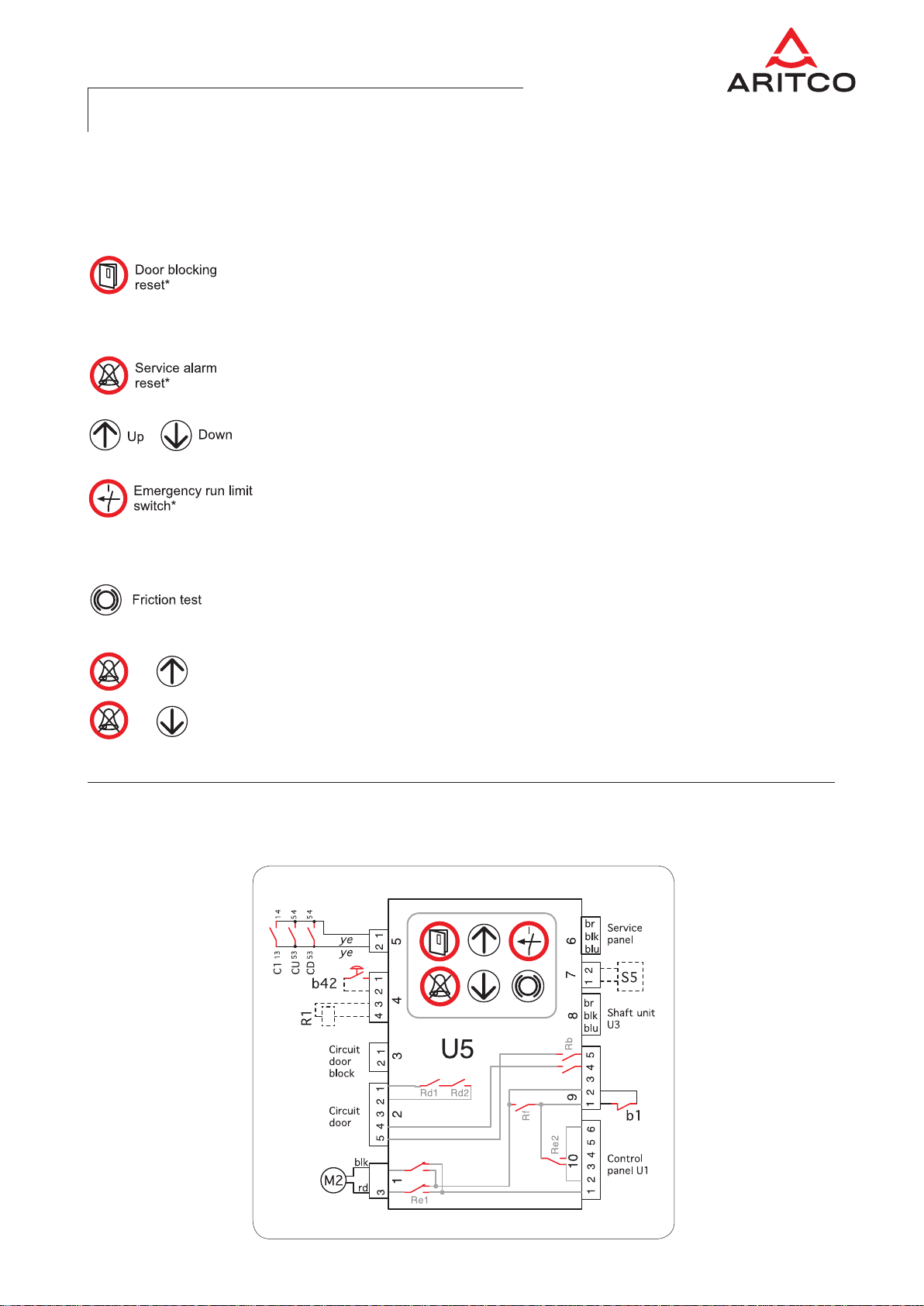

The control system is built with three kinds

of modules, i.e. the main controller (U1 module)

is placed in the cabin, U3 modules are placed

at each floor and one U5 module is connected

between the U1 and U3 modules.

The software in all modules is the same in

the 7000 series as in the 4000 and 2000

series, thus making them interchangeable.

Many features are built in by default:

•Error memory [ see page 15 ]

•Floor locking (school locking)

[ see page 8 ]

•Battery supervision [ see pages 7, 15 ]

•Emergency light supervision

[ see page 15 ]

•Automatic lubrication of screw

(adjustable) [ see page 12 ]

•Fire drive [ see page 12 ]

•Arrival signal On/Off [ see page 12 ]

•Call delay 2.5/5.0 seconds [ see page 12 ]

•Automatic cabin light off [ see page 12 ]

•Send cabin away from floor:

– Open the door, push desired floor button

inside the cabin for at least 3 seconds.

– Step outside, close the door and push the call button –

the lift will go to the floor you selected

•Backup power for emergency lowering down to the nearest floor

and keeping S3 (RM, Retiring ramp) locked when floor is school locked.

•Emergency lowering is executed by pressing any cabin destination button.

•Call buttons with error indication from the Error memory. [ see page 7 ]

•The floor indicator can display Run time and Number of starts. [ see page 13 ]

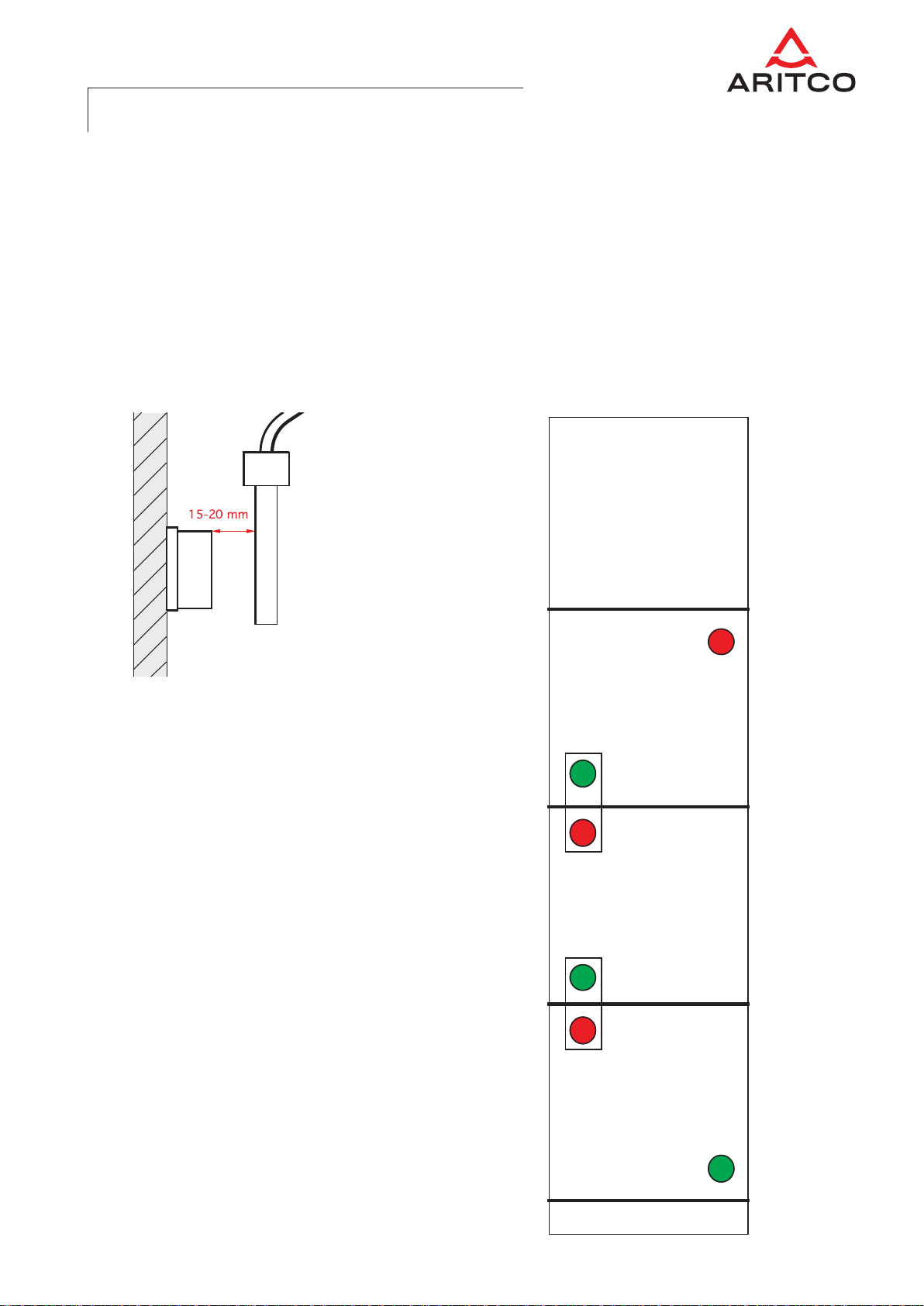

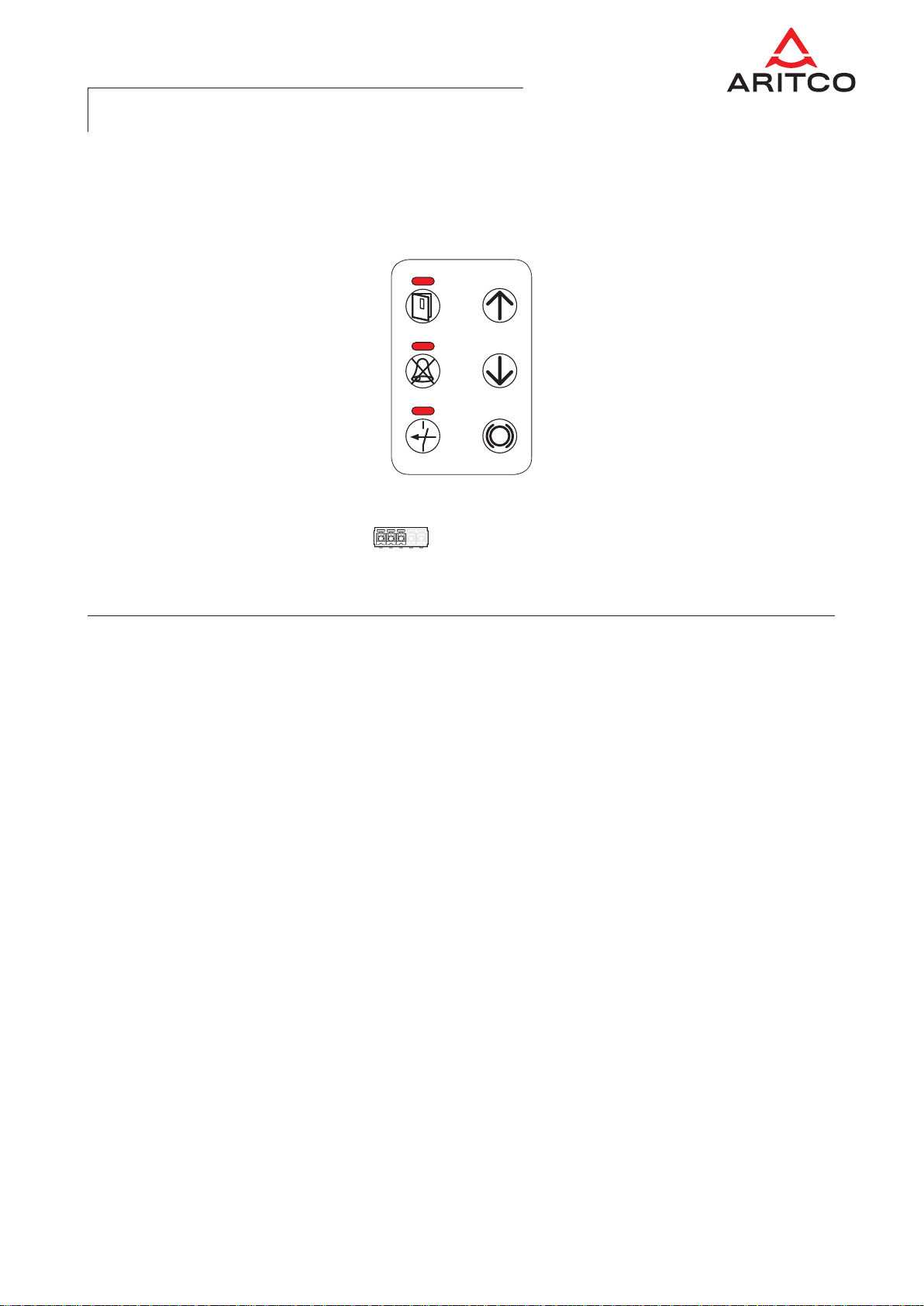

•Call button light is red or green.

Red light indicates an occupied mode and the lift will not respond.

The lift is occupied if:

– the cabin is in motion,

– a door is open

– someone using the lift has not yet reached their destination and

closed the door behind them

If necessary:

Reset the Lift occupied mode by pressing the Service alarm reset button