N 7

EN

37751

12-2014

2. Safety

2.2

Safety instructions applicable during operation, maintenance and repair

ãTerberg Machines B.V., IJsselstein, The Netherlands

All rights reserved. No part of this book may be reproduced, stored in database or retrieval system, or published, in any form or in any

way, electronically, mechanically, by print, photoprint, microfilm or any other means without prior written permission from the publisher.

During the operation of the bin lift system

•nsure that no-one is in the immediate vicinity of

the bin lift system during the loading cycle.

•If the bin lift system is in operation, you may under

no circumstances reach into the lifting system

(danger of injury).

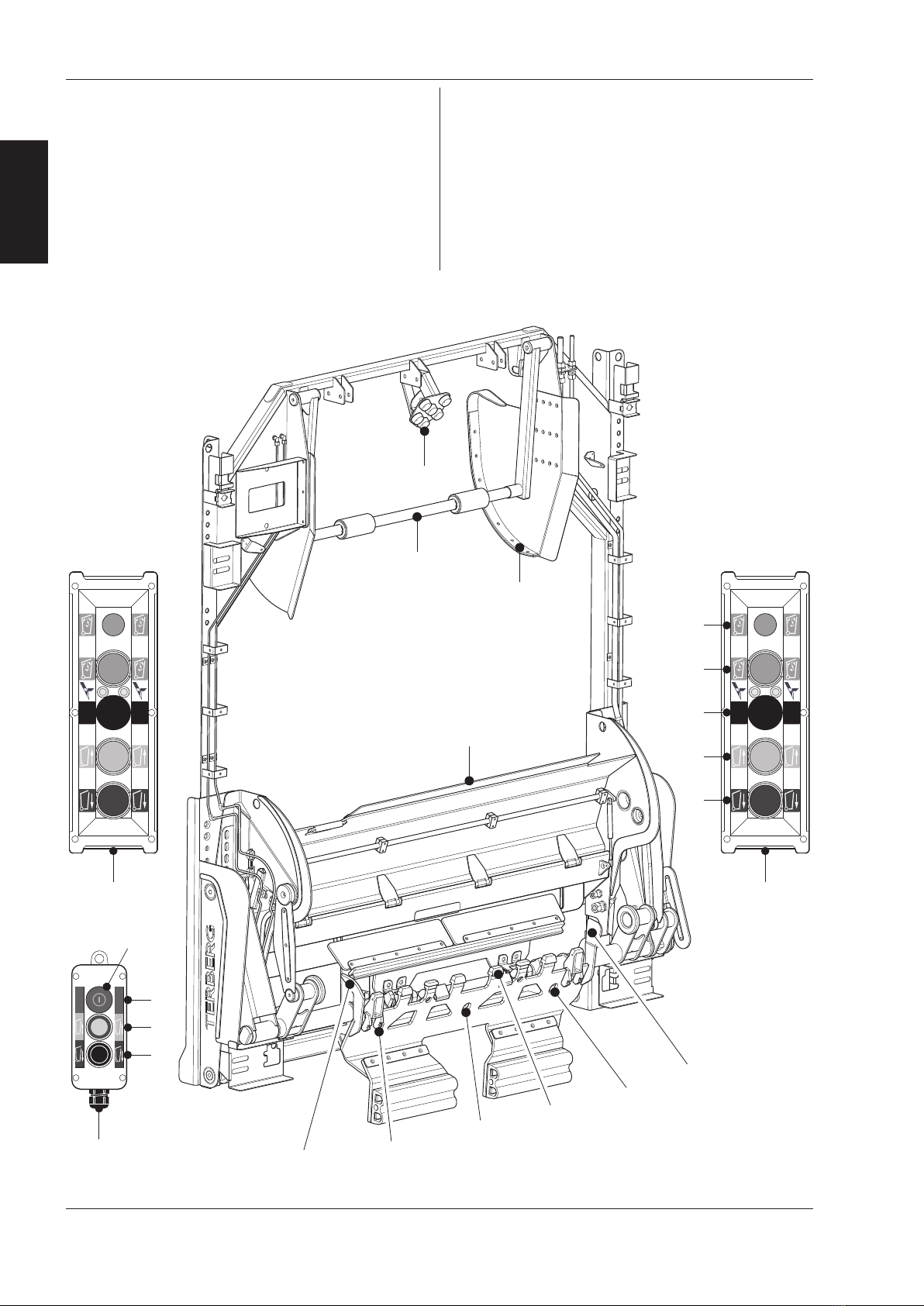

•In case of danger immediately press the closest

emergency stop switch

(see section Safety equipment 2.4).

•Check that there are no foreign objects in or

between the bin lift system that can hinder its

operation.

•Loose refuse may not be loaded above the edge

of the hopper.

•The compactor may not be used while objects are

protruding from the throw-in hole.

•Never use the bin lift system when the view of the

load is obstructed.

•Never use the bin lift system on a very uneven

surface.

•The bin lift system may not be driven up against a

bin/container or a pile of refuse.

•Take account of the heating of the hydraulic oil.

This can become 40°C warmer than the environ-

ment. As a result, the pipes and hoses can cause

light burns at high ambient temperatures.

•It is not permitted to use bin/container types not

listed in the manual.

•Nothing should protrude from the bin and only

bins whose lids are fully closed should be emptied.

•Do not empty any damaged bins. These can cause

problems.

•Overweight bins/containers should be removed

from the bin lift system:

max. lifting force 2-wheel bins: 1600N (160kg)

max. lifting force 4-wiel containers: 7500N (750kg)

•Check that the container is located correctly on

the pick-up comb or pick-up arms before you

empty it.

•Let go of the bin as soon as it is picked up by the

bin lift system.

•It is expressly forbidden to manually ‘help’ the lift-

ing system.

•Only give an extra shake if this is needed.

•Only remove the bin/container when the bin lift

system has come to rest and the bin/container is

back on the ground.

•Place empty bins/containers where they do not

pose a danger to other road users.

•It is forbidden to empty bins/containers that con-

tain dangerous and/or radioactive substances.

•It is not permitted to empty bins/containers that

contain burning or smouldering materials.

•Never walk backwards towards the bin lift system.

•One person offering and/or taking several bins at

the same time must be kept to a minimum.

•A bin may only be offered to the bin lift system

when held by the handle bars.

•During winter conditions, if the bin lift is contami-

nated by heavy snow or ice deposition on mecha-

nical parts or various sensors, the system can get

clogged up. Apply stop switch prior to cleaning.

Clean these parts and keep as dry as possible. For

example with a broom. Never clean the bin lift

using defrosting liquids!

During maintenance and repair

•Maintenance and repairs may only be carried out

by authorised technical personnel.

•Any faults detected should be corrected before

the bin lift system is used.

•For maintenance and repairs switch the bin lift sys-

tem off (switch off the engine of the refuse col-

lection vehicle and turn off the main power

switch).

•During repair work, accidental activation should

be prevented by removing the ignition key from

the ignition switch (keep on your person).

•You may not go under the tilt frame for repair or

cleaning unless the tilt frame is adequately sup-

ported.

•Before cleaning can begin, you should switch off

the drive gear of the refuse collection vehicle.

•The grease between the pivots may get washed

away if you use a high pressure cleaner. Think about

the safety of your eyes and use safety glasses.

•Use the lifting points present for raising the bin lift.

•When working on the hydraulic system, you should

bear in mind that this is filled with hydraulic fluid

under pressure. Always use personal protective

equipment to avoid contact with skin and eyes. Use

absorbents to avoid environmental pollution.

Keep a minimum distance of 2.5 meter

between the bin lift and objects which are

located behind the bin lift system. his is to

avoid a dangerous situation in case that a bin

comes loose.