3

Contents

PREFACE...........................................................................................................................5

'H¿QLWLRQVLQWKLV,)8 ...................................................................................................6

6$)(7<35(&$87,216............................................................................................7

,PSRUWDQW..............................................................................................................7

,VRODWRUVZLWFK......................................................................................................8

,QDQHPHUJHQF\..................................................................................................8

35(6(17$7,21..........................................................................................................9

2.1 Area of application ...............................................................................................9

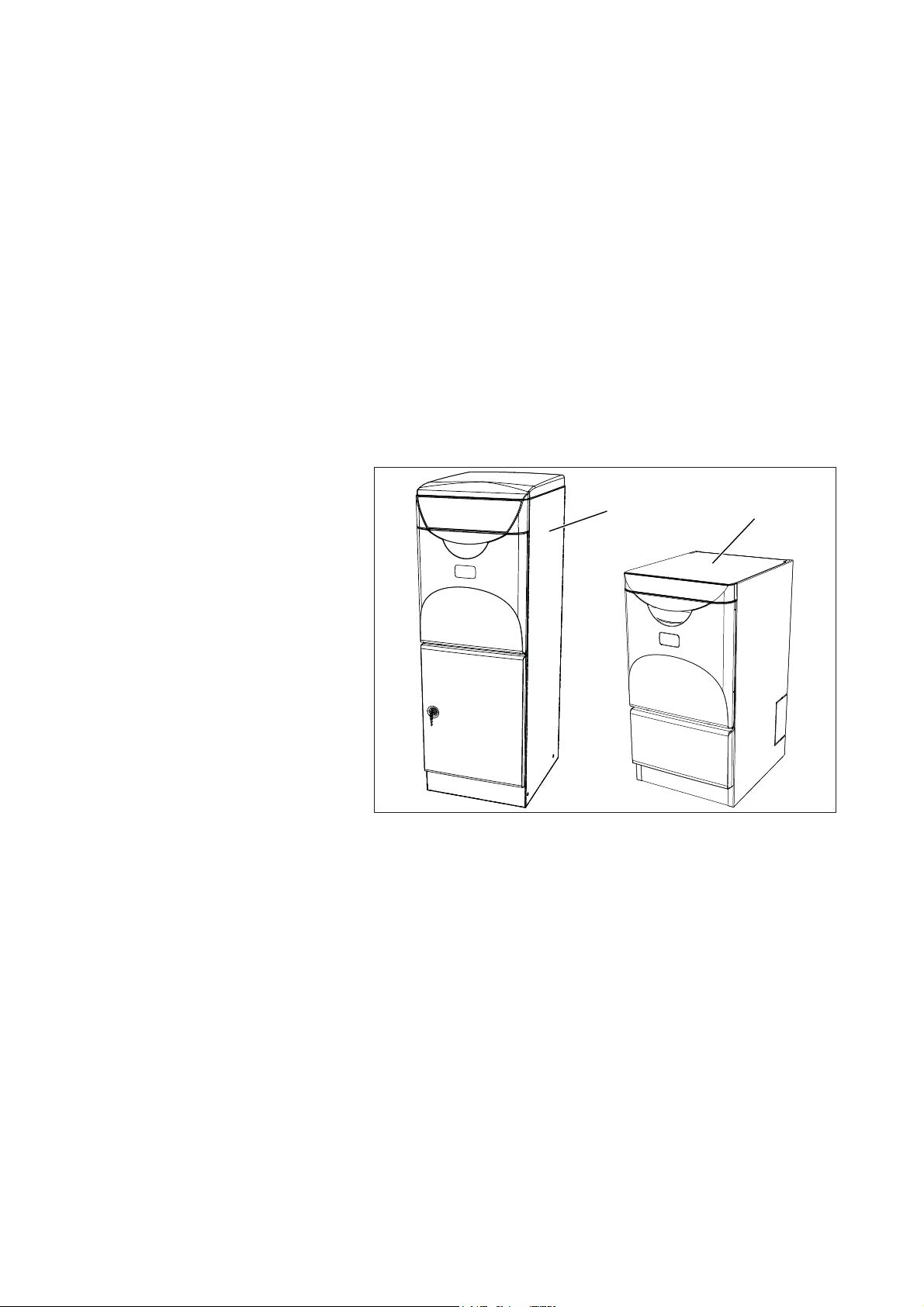

2.2 Models .................................................................................................................9

2.3 Control panel .....................................................................................................10

2.3.1 Components........................................................................................10

2.3.2 Functions ............................................................................................10

2.4 Display options ..................................................................................................11

2.4.1 Displayed while a program is running .................................................11

2.4.2 Display after program end...................................................................11

23(5$7,1*,16758&7,216 .................................................................................12

3.1 Program overview..............................................................................................12

3.2 Run a program...................................................................................................13

3.2.1 Start a program ...................................................................................13

3.2.2 During ongoing program .....................................................................13

3.2.3 After program completion....................................................................13

3.3 Cooling...............................................................................................................14

3.4 Examples of items and program selection.........................................................14

0$,17(1$1&( .........................................................................................................15

4.1 Flushing chamber ..............................................................................................15

4.2 The outside........................................................................................................15

4.3 Preventive maintenance ....................................................................................15

4.3.1 Periodic maintenance .........................................................................15

4.3.2 Service table .......................................................................................16

4.4 Machines that are not in use..............................................................................18

5 ALARM ........................................................................................................................19

5.1 Alarm indication .................................................................................................19

5.2 Acknowledgement of error message .................................................................19

5.3 During a power failure........................................................................................19

7528%/(6+227,1*...............................................................................................20

6.1 List of codes.......................................................................................................20

6.2 Types of codes...................................................................................................20

'(7(5*(17..............................................................................................................21

8VLQJGHWHUJHQW .................................................................................................21

7.2 Flushing detergent.............................................................................................21

7.3 Positioning .........................................................................................................22

7.4 Switching ...........................................................................................................22