3

Contents

PREFACE............................................................................................................................4

1 SAFETY PRECAUTIONS..............................................................................................5

1.1 Important..............................................................................................................6

1.2 Make sure assembly and installation work is carried out by................................7

1.3 Isolator switch......................................................................................................7

1.4 In an emergency..................................................................................................7

1.5 Product liability.....................................................................................................7

1.6 Attention symbols.................................................................................................7

2 INSTALLATION..............................................................................................................8

2.1 General................................................................................................................8

2.1.1 Make sure assembly and installation work is carried out......................8

2.1.2 Installation order ...................................................................................8

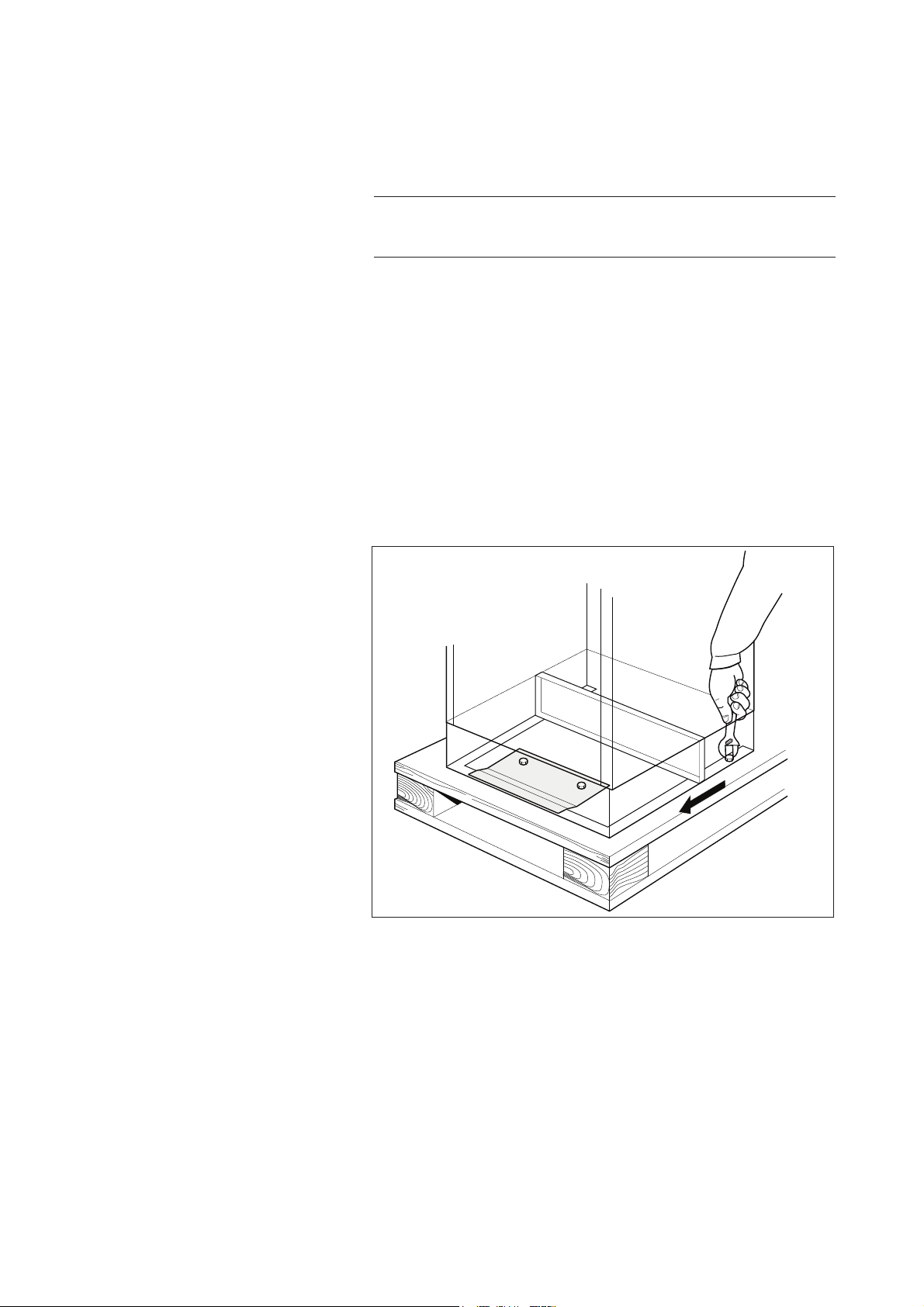

2.2 Unpacking............................................................................................................9

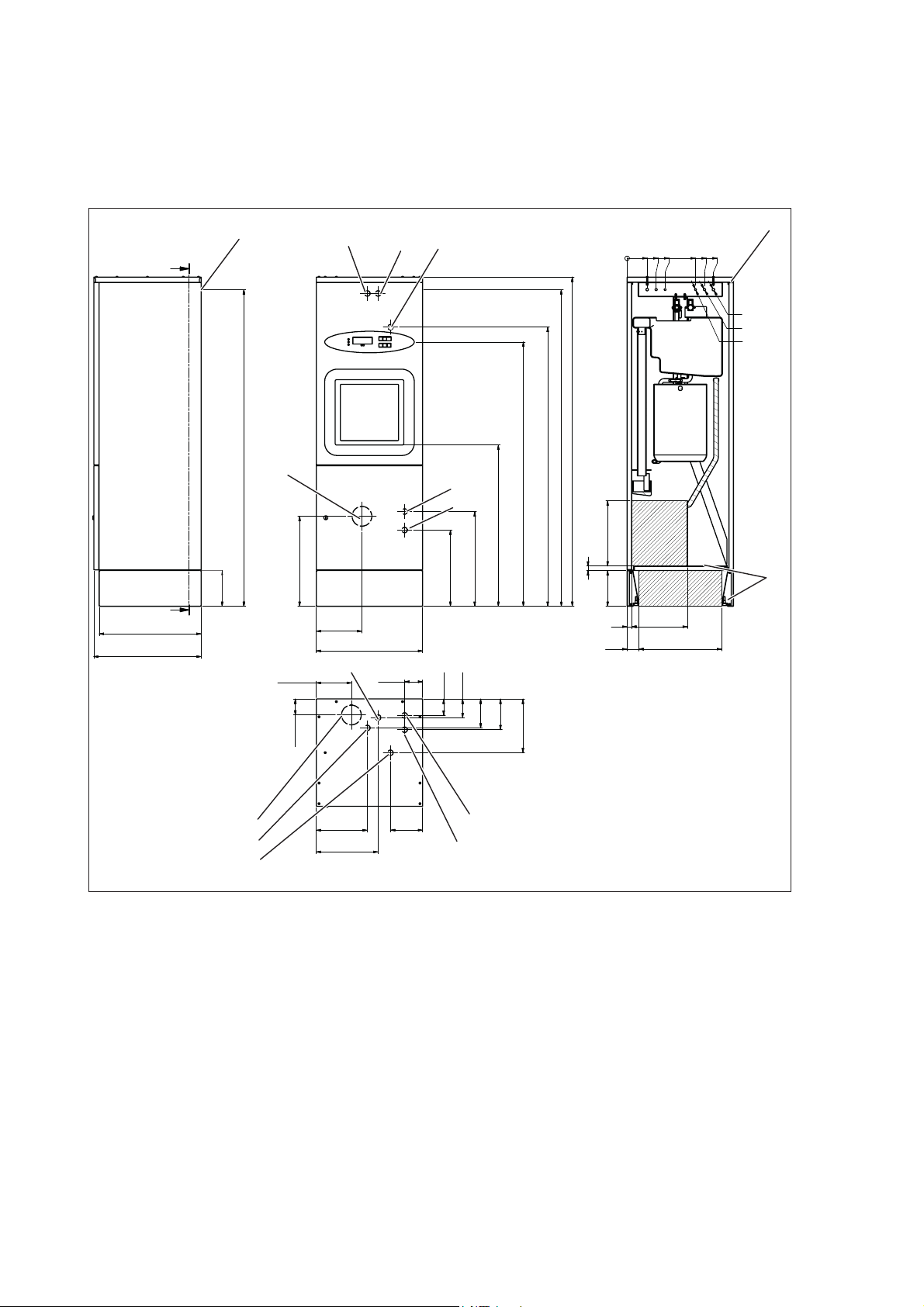

2.3 Diagram showing dimensions and hole pattern.................................................10

2.4 Positioning .........................................................................................................11

2.5 Connecting water...............................................................................................14

2.6 Connecting electric power .................................................................................14

2.6.1 Coupling alternative ............................................................................15

2.7 When the work is complete, check that .............................................................16

2.8 Function check...................................................................................................17

3 TECHNICAL DATA.......................................................................................................19

3.1 Dimensions and weights....................................................................................19

3.2 Connections.......................................................................................................20

3.3 Miscellaneous....................................................................................................21

3.4 Environmental requirements..............................................................................21

3.5 Protection class .................................................................................................21

3.6 Accessories........................................................................................................22

4 WATER QUALITY........................................................................................................23

5 END OF LIFE DISPOSAL............................................................................................25