CONTENTS

INSTRUCTION MANUAL

Ⅰ.PRECAUTIONS BEFORE STARTING OPERATION................................................ 1

Ⅱ.SPECIFICATIONS....................................................................... 1

Ⅲ.CAUTIONS ON USE ..................................................................... 2

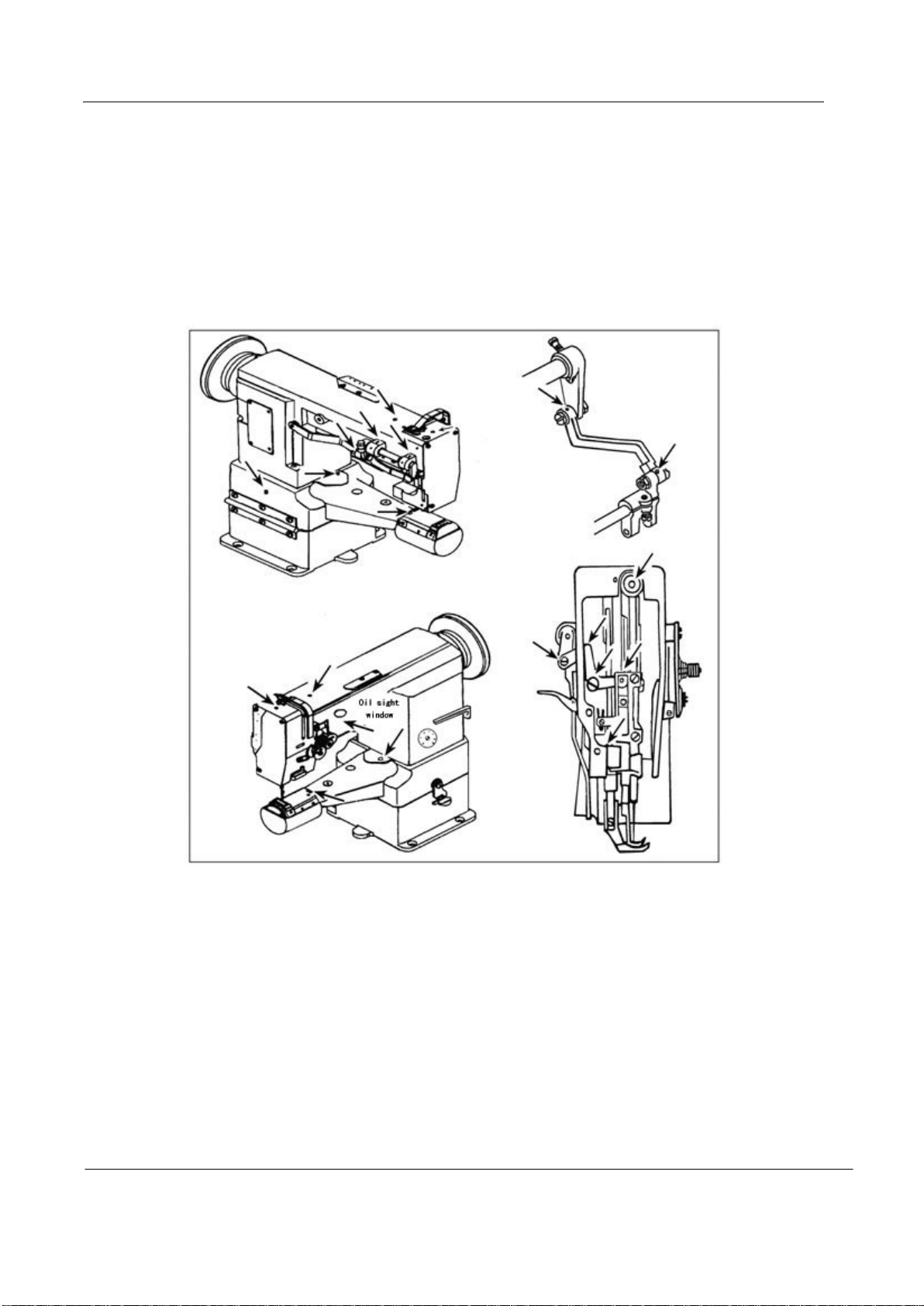

1. Lubrication ......................................................................... 2

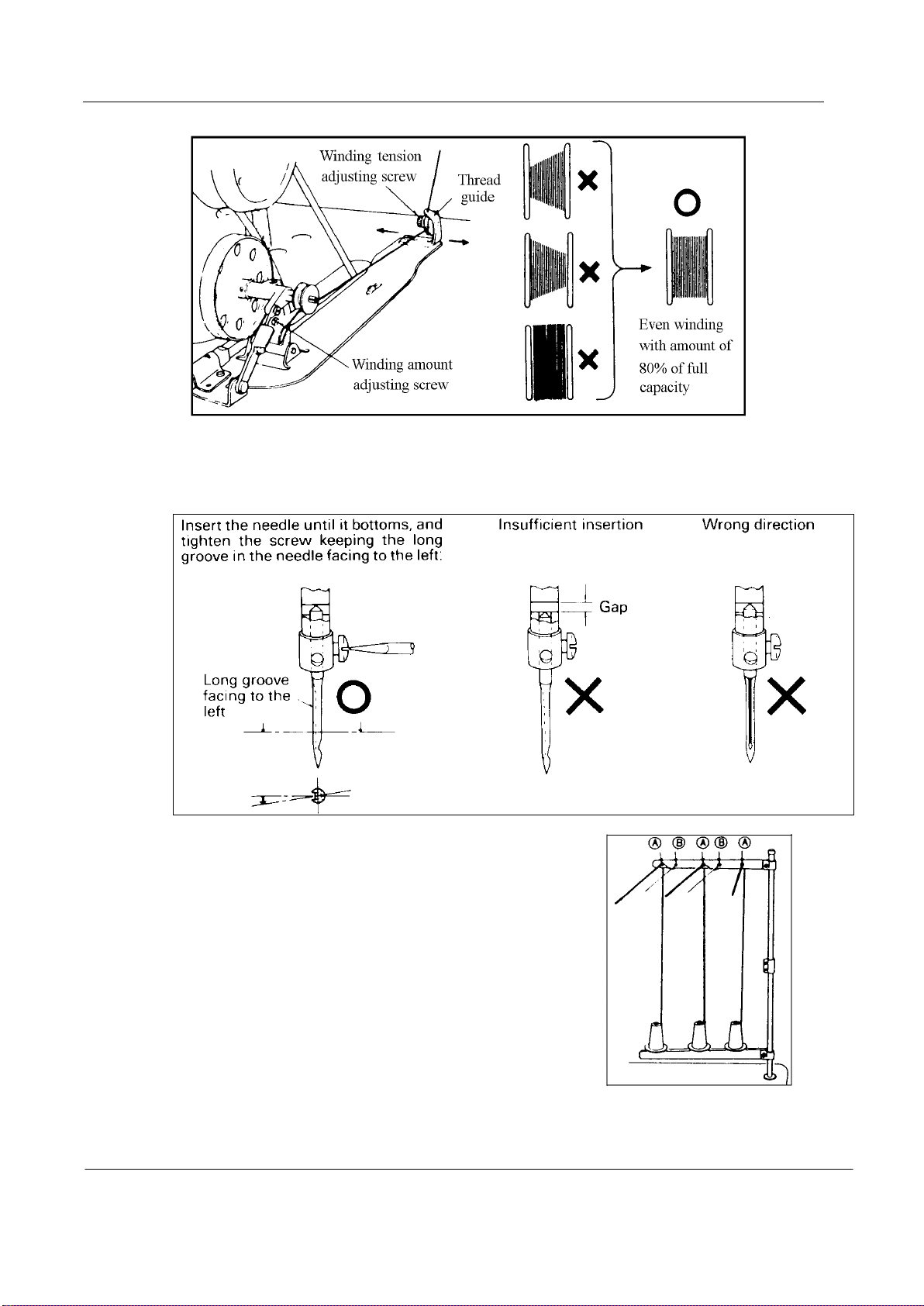

2. Winding of bobbin thread ............................................................ 2

3. Attaching the needle ................................................................ 3

4. Threading of needle threads ......................................................... 3

5. Setting of bobbin ................................................................... 4

6. Threading of bobbin threads......................................................... 4

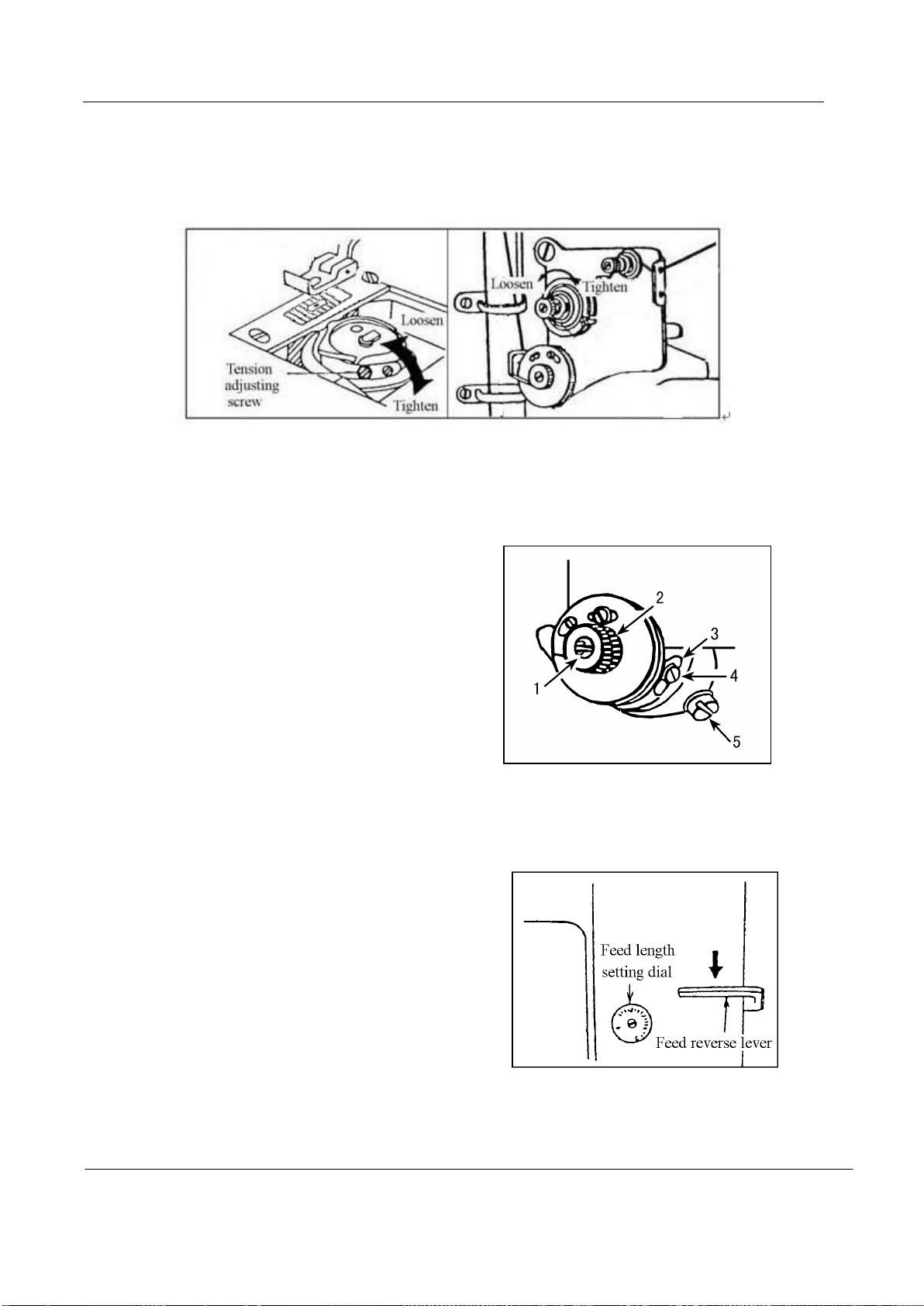

7. Thread tension ...................................................................... 4

8. Thread take-upspring ................................................................ 5

9. Adjusting the stitch length ........................................................ 5

10. Adjusting the pressure of the presser foot ......................................... 6

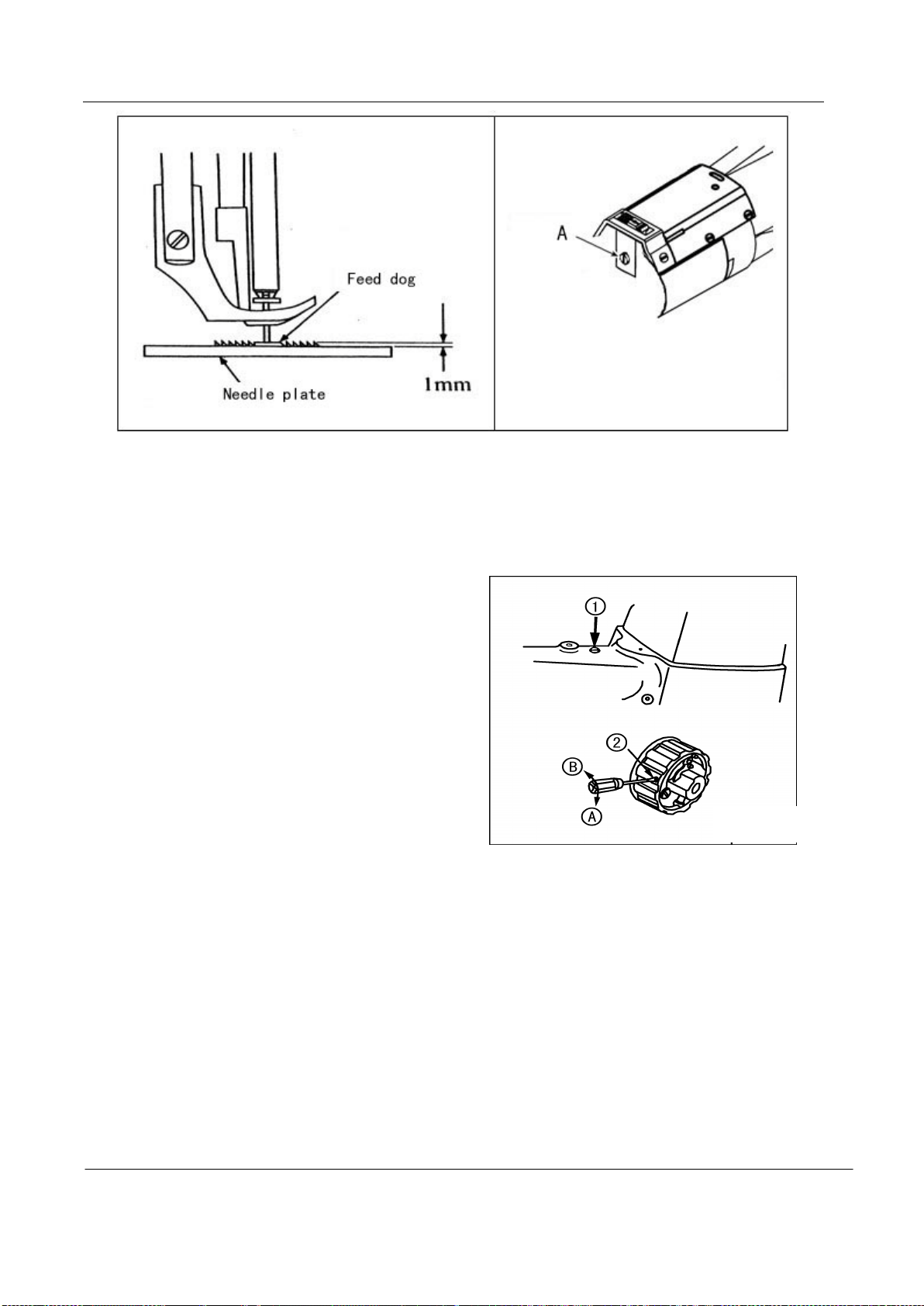

11. Adjusting the presser foot and the walking foot .................................... 6

12. Timing between rotating hook motion and needle motion .............................. 6

13. Relationship between hook motion and opener motion ................................. 7

14. Relationship between needle motion and feed dog motion ............................. 7

15. Adjusting the height of the feed dog ............................................... 7

16. Safety mechanism ................................................................... 8

CATALOG

A. ARM BED AND ITS ACCESSORIES.......................................................... 9

B. THREAD TENSION REGULATOR MECHINISM.................................................. 12

C. ARM SHAFT MECHANISM................................................................. 15

D. NEEDLE BAR &THREAD TAKE-UP LEVER MECHANISM........................................ 17

E. PREAAER FOOT MECHANISM ............................................................ 19

F. STITCH REGULATOR MECHANISM.......................................................... 22

G. FEEDING AND FEED LIFTING &ROTATING HOOK SHAFT MECHANISM........................... 25

H. HOOK SADDLE MECHANISM............................................................... 27

I. ACCESSORIES ....................................................................... 29