hand-held programming unit and the motor control unit

-> Hand-held programming unit, motor electronics or

spiral cable of the hand-held programming unit defective

CPM-DEVICE ERROR: General mistake in the motor

control unit

-> Replace motor electronics (see chapter 7.3) if

persistent

MOT. EN. TIMEOUT: Motor can not be activated

-> Check motor electronics and plug connection for

motor. Replace motor electronics (see chapter 7.3) and

spiral cable of the hand-held programming unit if

persistent

INVALID PARAMET.: Motor control unit received a

parameter

-> Hand-held programming unit, motor electronics or

spiral cable of the hand-held programming unit defective

STOP RELEASE ERR: Stop line can not be released

-> Remove hand-held programming unit or spiral cable

(see chapter 7.2) if persistent

UNEXP. MOT. STOP: Motor stopped unexpectedly

-> Motor electronics or connecting line to motor defective

MOTOR DISABLED: Motor is disconnected

-> Motor electronics or connecting line to motor defective

MOTOR ERROR: Motor is not turning

-> Check motor cable and motor. Replace motor

electronics (see chapter 7.3) if persistent

RTC INIT ERROR: Hand-held programming unit defective

-> Replace hand-held programming unit (see chapter7.2)

if persistent

RTC COM ERROR: Communication problem with hand-

held programming unit

-> Replace hand-held programming unit (see chapter7.2)

if persistent

RTC ERROR: Hand-held programming unit defective

-> Replace hand-held programming unit (see chapter7.2)

if persistent

RANGE EXCEEDED: Potentiometer shows a value out

of range

-> Replace Potentiometer and/ or spiral cable

UNKNOWN CPM ERR.: Unknown error in the motor

control unit

-> Replace motor electronics (see chapter 7.3) if

persistent

UNDEFINED ERROR: Undefined error

-> Hand-held programming unit, motor electronics or

spiral cable of the hand-held programming unit defective

CPM 24V SUPPLY: 24V supply in motor control out of

range

-> Check power supply. Replace motor electronics (see

chapter 7.3) if persistent

range

-> Replace motor electronics(see chapter 7.3) if persistent

HS 24V SUPPLY: 24V supply in hand-held programming

out of range

-> Replace hand-held programming unit or spiral cable if

persistent

HS 5V SUPPLY: 5V supply in hand-held programming unit

out of range

-> Replace hand-held programming unit if persistent

HS 3.3V SUPPLY: 3.3V supply in hand-held programming

unit out of range

-> Replace hand-held programming unit if persistent

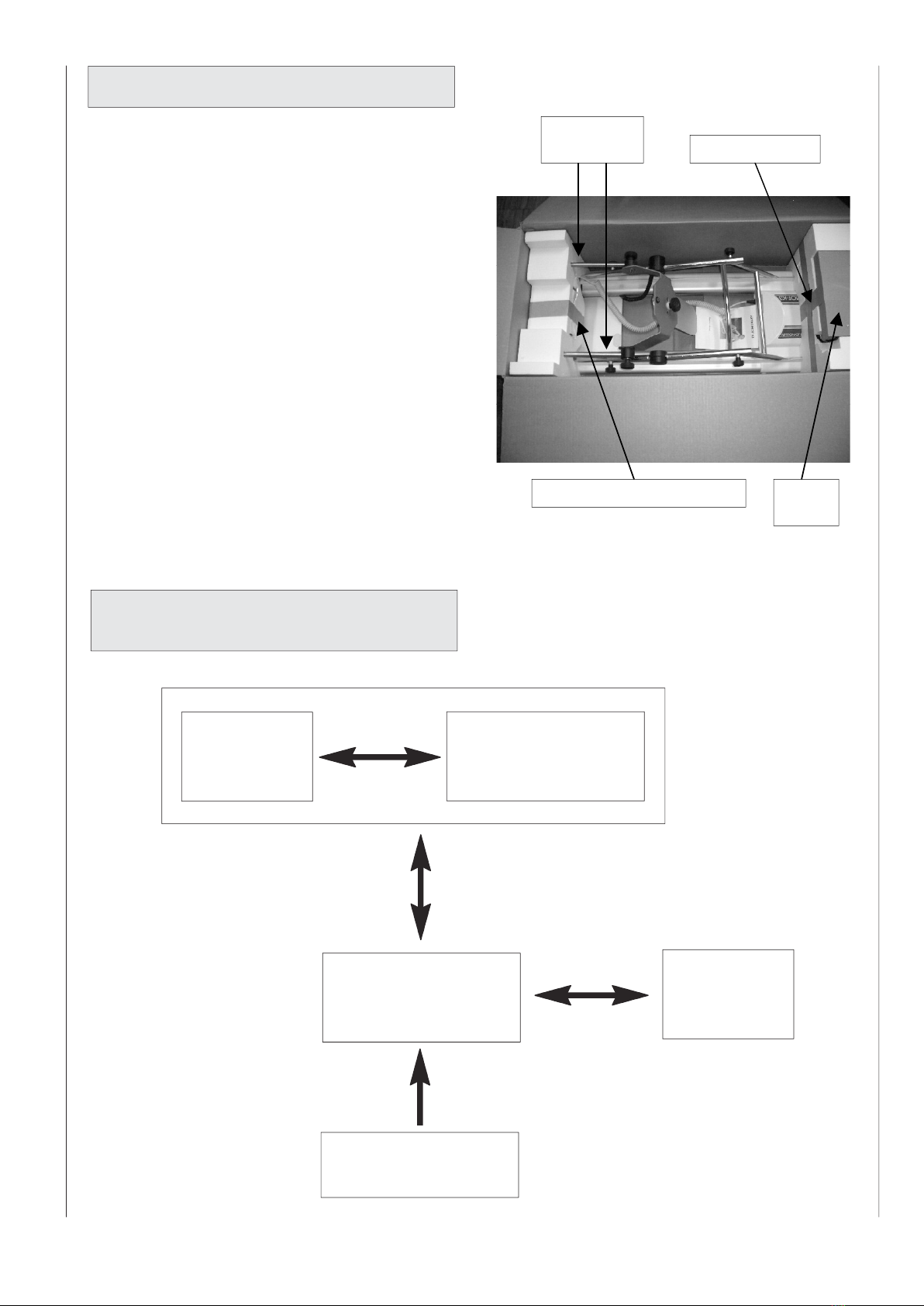

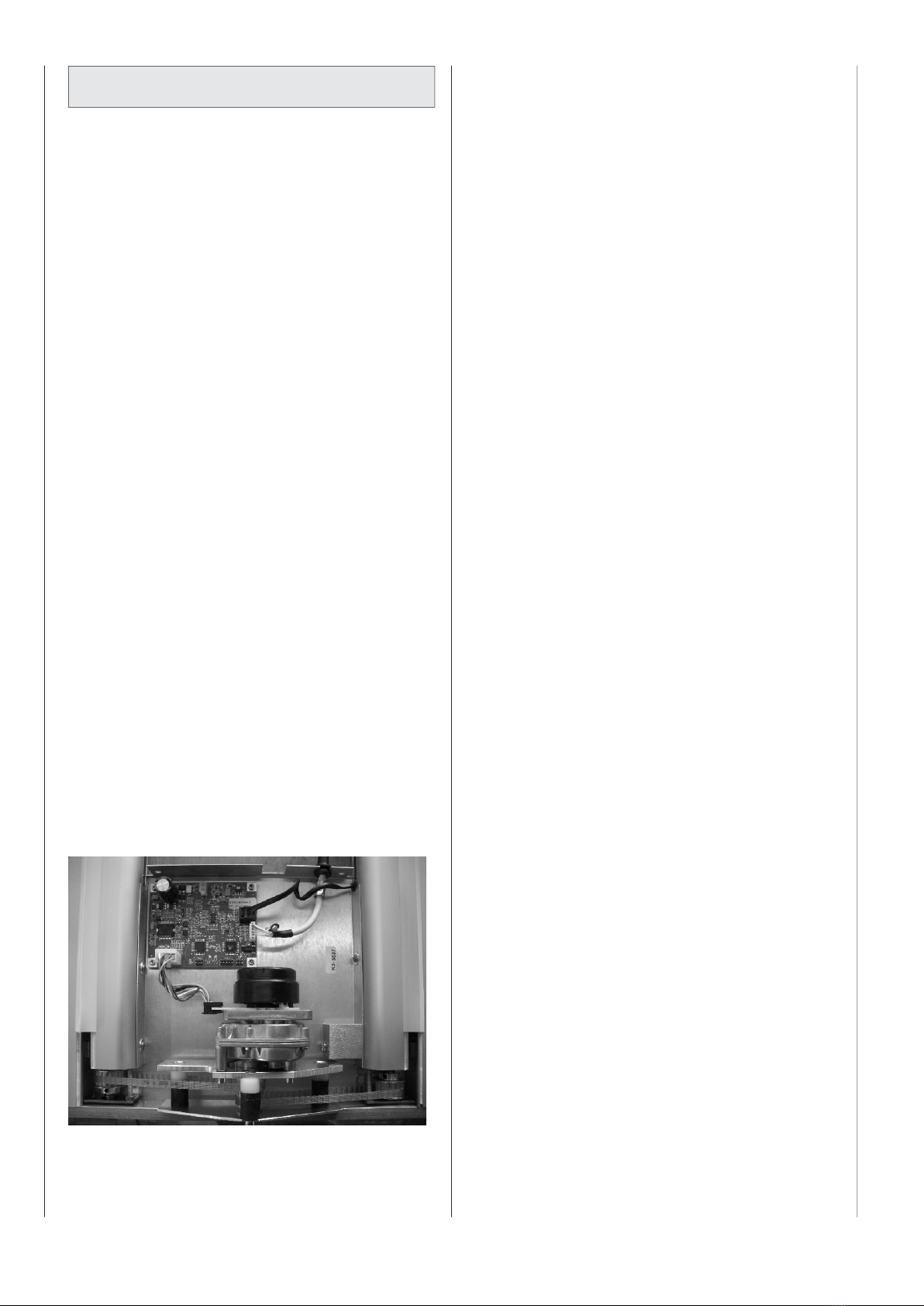

3.2 Mechanics

ARTROMOT®-K3 serial number < 3000.

Do not loosen the knurled handles completely for any

adjustment. For operation or transport, make sure that

the knurled handles are tight.

or oil.

Do not utilize any solvent for cleaning the

ARTROMOT®-K3.