8

7. How to perform the repair

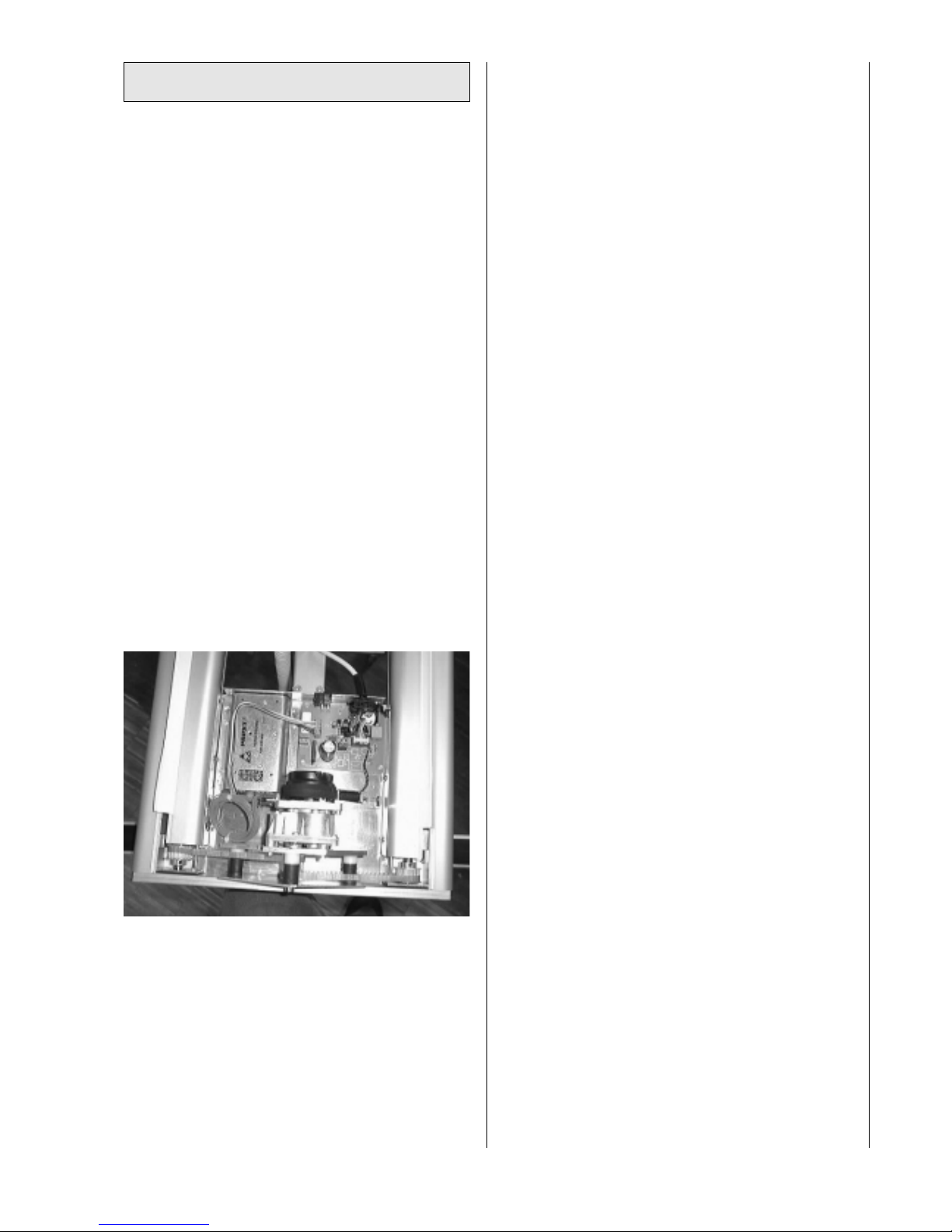

7.1 How to remove the casing (Pos. 3.12)

■Move the ARTROMOT®-K3 in a position of approximately

110 degrees.

■Turn the power OFF at the ARTROMOT®-K3 and remove

the power adapter.

■Hit the 4 pins of the split rivet (Pos. 3.24) inwards.

■Remove the 2 covering plates (Pos. 3.22)

■Loosen the 2 countersunk screws (Pos. 3.50) and remove

the casing.

■Remove the 4 pins of the split rivet, which are inside the

casing.

■If you have exchanged any of the printed circuit boards

including the knee elec-tronics and the hand held pro-

gramming unit or any parts of the drive technology (Pos.

3.x), you have to perform a reference run. See chapter 7.4

■Finally, a function- and safetytest has to be performed.

7.2 How to exchange the hand-held programming unit

(Pos. 1.2)

■Remove the casing. See chapter 7.1

■Pull out the connector of the hand held programming unit.

Attention: Use your ESD (Electro Static Discharge)-

equipment.

■Put in the connector of the new hand held programming

unit.

■Rebuild the casing.

■Perform a reference run. See chapter 7.4

■Finally, a function- and safetytest has to be performed.

7.3 How to exchange the motor electronics

(Pos. 1.3 and 1.6)

■Remove the casing. See chapter 7.1

■Pull out the required cables at the printed circuit board

(Pos. 1.6)

Attention: Use your ESD (Electro Static Discharge)-

equipment.

■Exchange the defect printed circuit board.

■Put in the cables at the same position. (Pay attention to

the code)

■Rebuild the casing.

■Perform a refernce run. See chapter 7.4

■Finally, a function- and safetytest has to be performed.

7.4 How to perform a reference run.

(Reference run connector: 0.0031.007)

■Move the ARTROMOT®-K3 in a position of approximately

10 degrees.

■Turn the power OFF at the ARTROMOT®-K3.

■Adjust a maximum femur length.

■Open the housing of the hand-held programming unit

vis-à-vis to the spiral cable side. At the printed circuit

board is an unused socket. Insert the reference run

connector at this socket. (Pay attention to the code)

■Turn the power ON at the ARTROMOT®-K3.

■The display shows „REFERENCE RUN"

■Press „START"

■After about 2 minutes, when the ARTROMOT®-K3

reached both points of changing direction, (first minimum

at EXTENSION = -5 degrees afterwards maximum at

FLEXION = 127 degrees) the ARTROMOT®-K3 will stop at

EXTENSION / FLEXION = 110 degrees.

Attention: It is important to push or pull at the femur

bow so that in direction Flexion the ARTROMOT®-K3

reach the mechanical stud. (approximately 3 cm in front of

the right/left cover). (Pos. 2.8/2.9)

■Pull out the reference run connector.

■Turn the power OFF at the ARTROMOT®-K3 and close

the housing of the hand-held programming unit.

■Finally, a function- and safetytest has to be performed.