8

ECOcycle Aurora Ⅱ

NameofItem CodeNo. ExplanationoftheItem

LimitScaleLS-45 Ⅱ

LS452 Scaletobeusedtopreventover-fillingwhenrecovery

cylinderhasnooatsensor.

LimitScaleLS-150 Ⅱ

LS152

ARmolecularsievepack

AR222

ReplacementmolecularsieveforinsideofMolecularsievepack.

Chargefaster

WA6625 UsewhenrecoveringR134aandR12.

CheckMate

RT700K EasilycalculationPPMforcontaminate of oil and

moisture/acidofrefrigerant.

RefrigerantAnalyzerUltimaHV

NT2004HV Judgmentofrefrigerantifpossibletouseforreclaim.

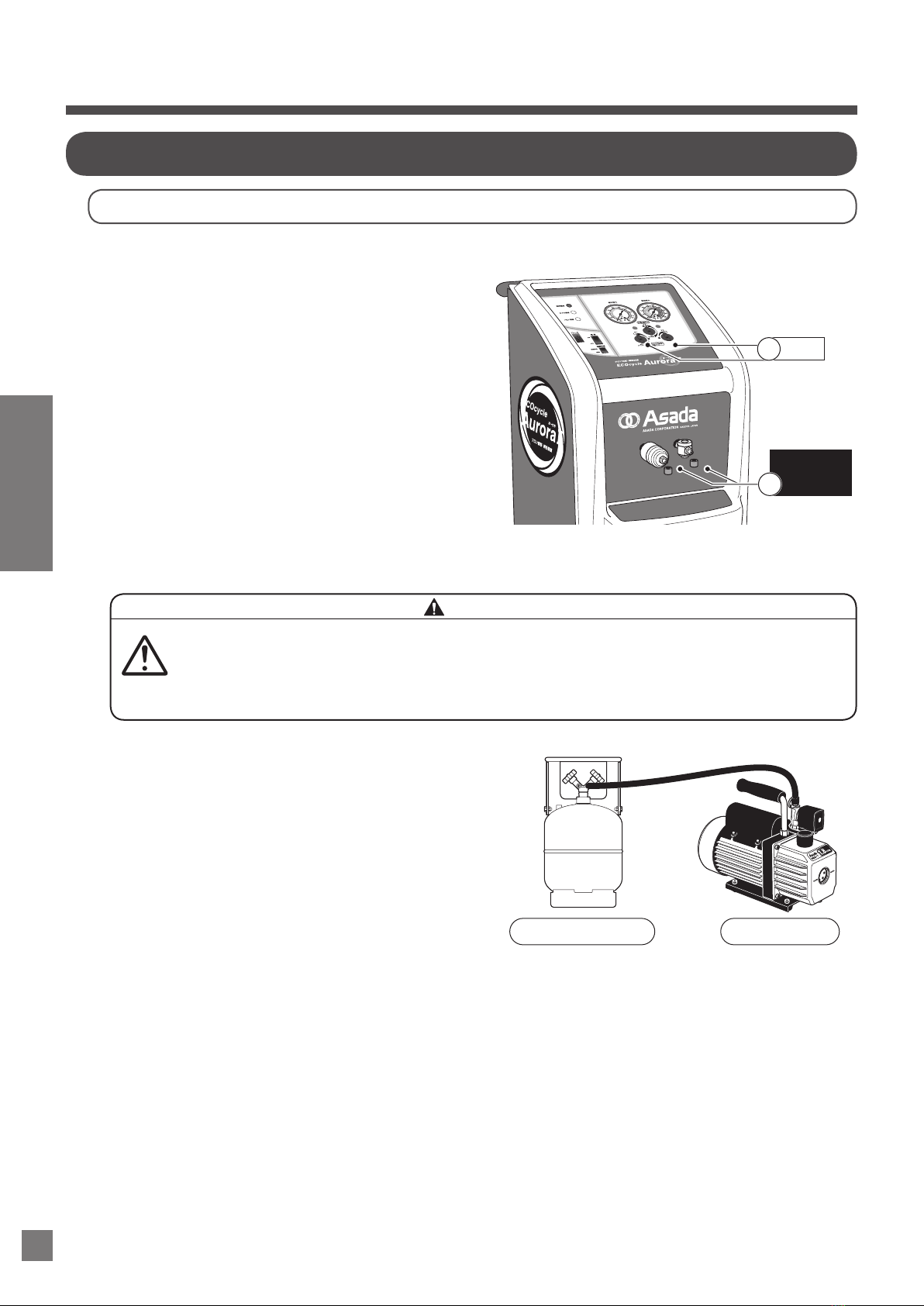

VacuumPump

Various

Type Highecient2-stagevacuumpumpwithacheckvalve.

CoolingunitCL3(3/8")

ES801

Improvestheefficiencyofrecoveryinsummerclimate,

recoveryinalargevolumeorrecoveryof R410A by

usingtogetherwitharecoverymachine.

Header

TF013 Recoveryofupto6unitsatthesametime.

Piercingvalve

TF014

Makesaconnectionportforrecoveryfromasystem

whichhasnoserviceportsuchasahomeuse

refrigerator,etc.

1/4"Charginghosewithpressure

gauge(forusewithcylinder)

Y02002A Connecttorecoverycylinderandchecktheamountofair

mixedintherefrigerant.

1/4"Hosewithvacuumneedle

Y02003A Checksdepthofvacuuminthesystembeingrecoveredto

judgecompletionofrecovery.

SightGlass

Y41145 Visuallycheckrefrigerantoweitherinvapororliquid.

Adapterfordierentdiameter

forautoA/C(quicktype)3/16"

femalex1/4"male

Y19120 Adaptertoconnecttothesmallserviceport(3/16") for

R12.

Highpressurequickjoint

forR134a(M12)

Y03100A Forquickconnectiontotheserviceport(highpressure

side)forR134a.

Lowpressurequickjoint

forR134a(M10)

Y03200A Forquickconnectiontotheserviceport(lowpressure

side)forR134a.

1/4”BallValve

Y93843 PreventreleaseofrefrigerantwhenDisconnectinghose.

QuickchargingvalveA

Y18975 Canbeusedwithoutleakingrefrigerant.

RecoveryspeedimproveswithoutSchrader.

Charginghoseplus Ⅱwith

SealRighttting

Various

sizes

available

Lowlossanti-blowbackSealRightfittingtraps

refrigerantinthehosewhendisconnected.

Charginghoseplus Ⅱ forR410A

CharginghoseforR410A.

Charginghoseplus Ⅱ with

ballvalveforR410A

CharginghosewithballvalveforR410A.

Charginghoseplus Ⅱ forR134a

CharginghoseforR134a.

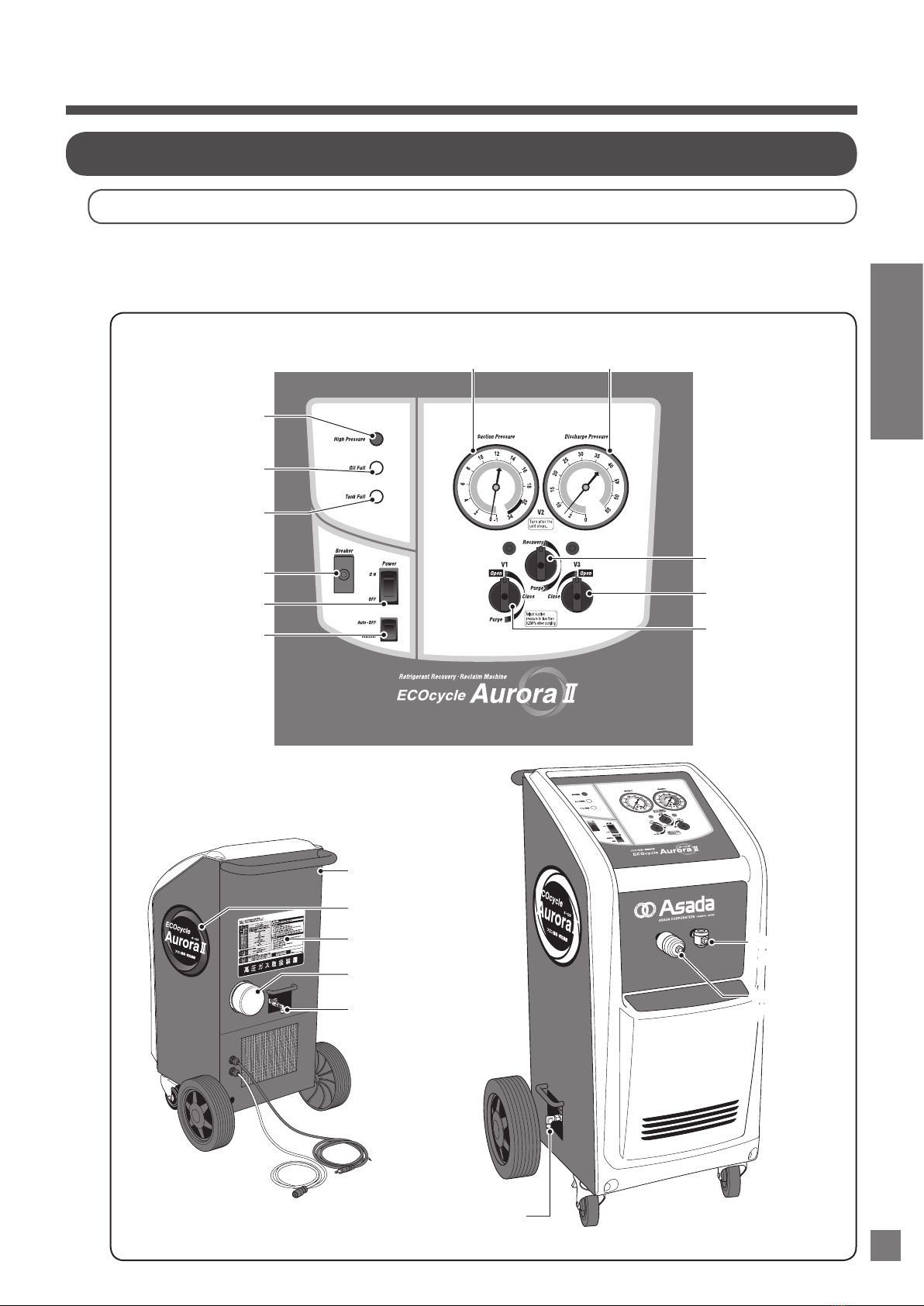

COMPONENTSOFTHE

MACHINE

* OurLimit Scale must be usedwhenrecovery

cylinders(withoutoatsensor)areused.

* Ouroriginalrecoverycylindershouldbeused.

Description Capacity Port CodeNo.

Refrigerant

recoverycylinder

(withoatsensor)

1L

1/4"are

TF040

6L TF090

12L TF056

24L TF057

40L

1/4"are

TF130

3/8"are

TF131

120L

1/4"are

TF110

3/8"are

TF129

1/2"are

TF097

3/4"are

TF098

Description Capacity Port CodeNo.

Refrigerant

recoverycylinder

(withoutoatsensor)

24L

1/4"

are

TF080

120L TF070

OptionalAccessories(OtherAir-ConditioningEquipment)

OptionalAccessories(RecoveryCylinder)