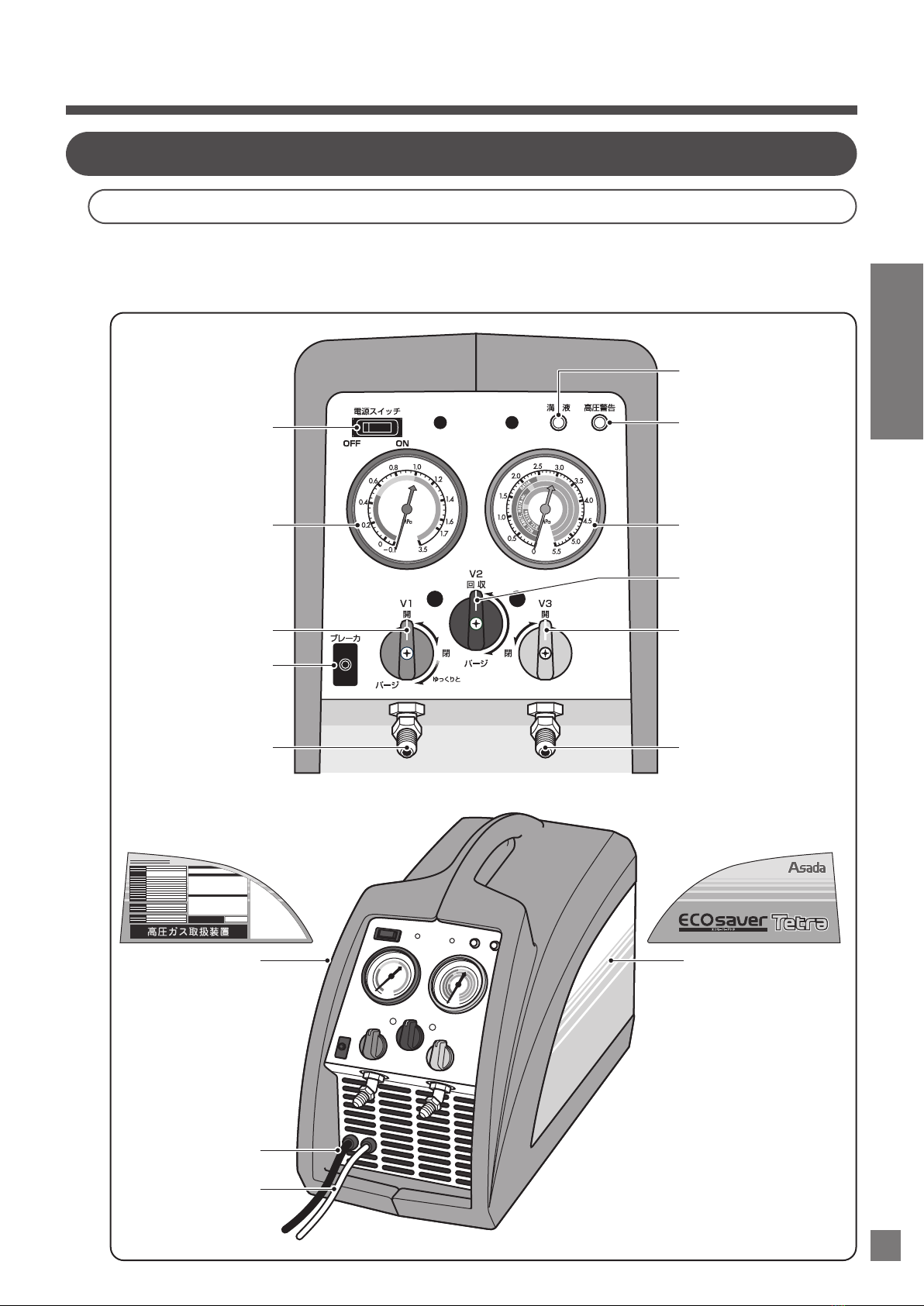

ECOsaver Tetra

9

HOWTOUSE

HOW TO USE

PreparationbeforeOperation

● “Transportation” and “Evacuation of the air

in the cylinder” should be done in view of

the following environment of usage.

① Do not use the machine in rain or in areas

where water may enter into the machine.

A fan is built into the machine for cooling

and it may suck water.

② The recovery machine should be used in a

well-ventilated area.

When the machine is used in a poor

ventilated area, you may be choked from

lack of oxygen in case of refrigerant leak.

③ Keep re away to prevent phosgene (highly

toxic substance) being generated.

④ Combustible gases (hydrocarbon system)

cannot be recovered.

If any combustible gases [ammonia,

hydrocarbon (propane, isobutene) and so

on] enter into the recovery machine, it may

catch re and may explode.

● Please note the following points before use.

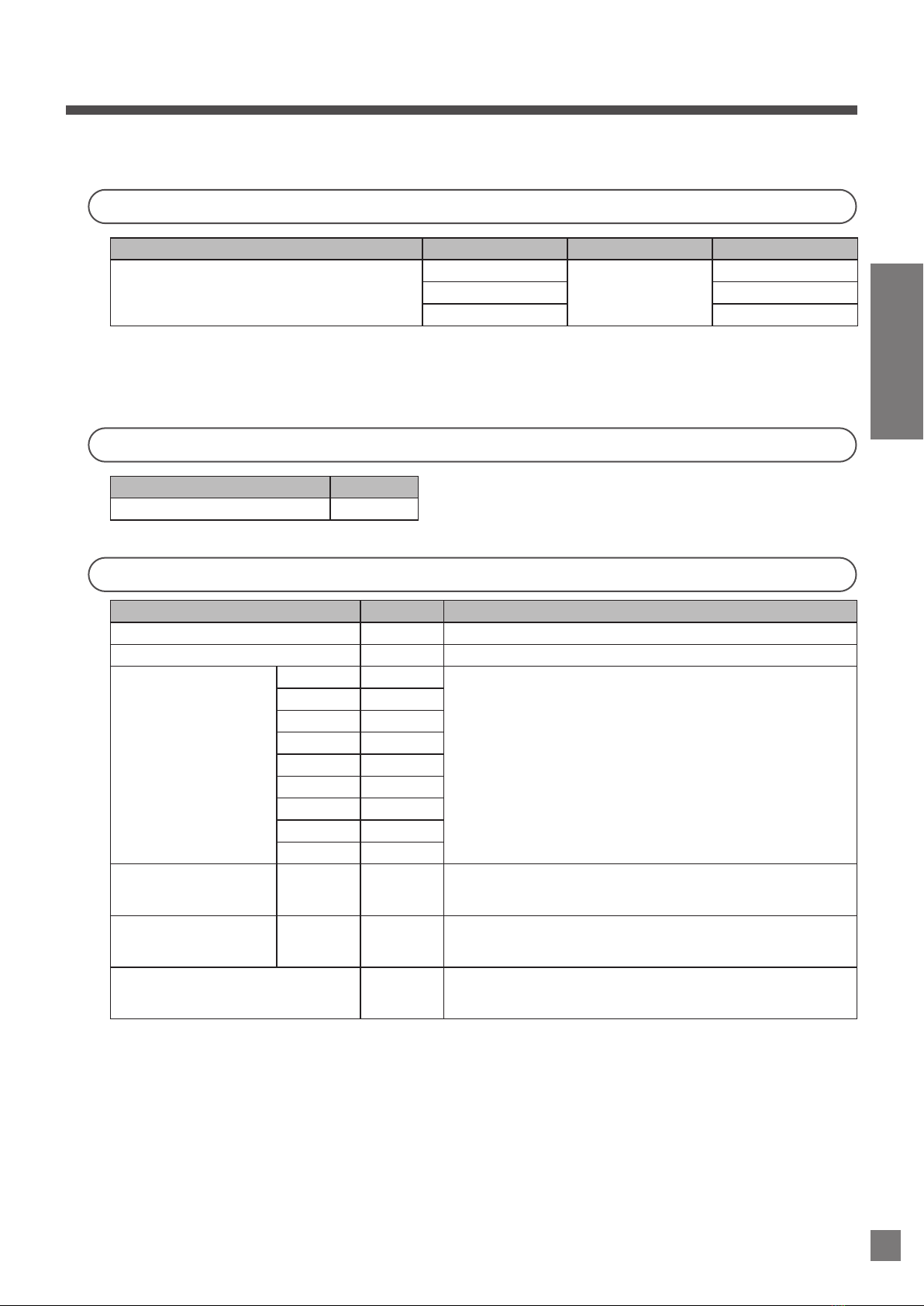

① Evacuate the air from the refrigerant

recovery machine, charging hoses and

recovery cylinder (hereinafter called

recovery machine, hoses and cylinder).

② Install a lter or a lter dryer at the suction

port of the recovery machine.

③ Close the suction valve before starting the

recovery machine.

④ Abnormal noise may be heard when large

amount of liquid refrigerant enters into the

compressor.

Throttle the suction valve until the noise

cannot be heard.

⑤ Do not close the discharge valve or the

valve of the cylinder before stopping the

recovery machine during operation.

The discharge gauge may be damaged.

Close the valve on the manifold, stop the

recovery machine and then close the valves

at the discharge (high pressure) side.

⑥ The temperature of the cylinder may rise

when the ambient temperature is high or

R410A is recovered.

Lower the temperature and pressure of the

cylinder according to “page 10 4) Helpful

Information” and “page 15 Recovery

Procedure of R410A or When the Pressure

of Refrigerant is High”.

⑦ Do not enter the air into the hoses and the

cylinder.

When the cylinder contains air, evacuate

the air from the vapor valve referring to

the chart of saturation temperature and

pressure.

The air can be evacuated before discharging

the refrigerant.

⑧ Use an oil separator when refrigerant with a

large amount of oil is recovered.

The compressor may be damaged when a

large amount of oil is recovered.

⑨ Do not recover virgin refrigerant.

The compressor may be damaged if virgin

refrigerant is recovered for a long time.

If you need to recover virgin refrigerant, put

some additional oil in the compressor.

⑩ Do not recover from air conditioners in

which any sealant has ever been charged.

The sealant may clog the valves or the

compressor and the recovery machine may

be damaged.

⑪ Do not evacuate the air from the cylinder by

using the recovery machine.

The compressor may be damaged if it is run

for a long time under vacuum.

⑫ Do not leave refrigerant in the recovery

machine.

Always open the suction port and the

discharge port when the recover machine is

stored.

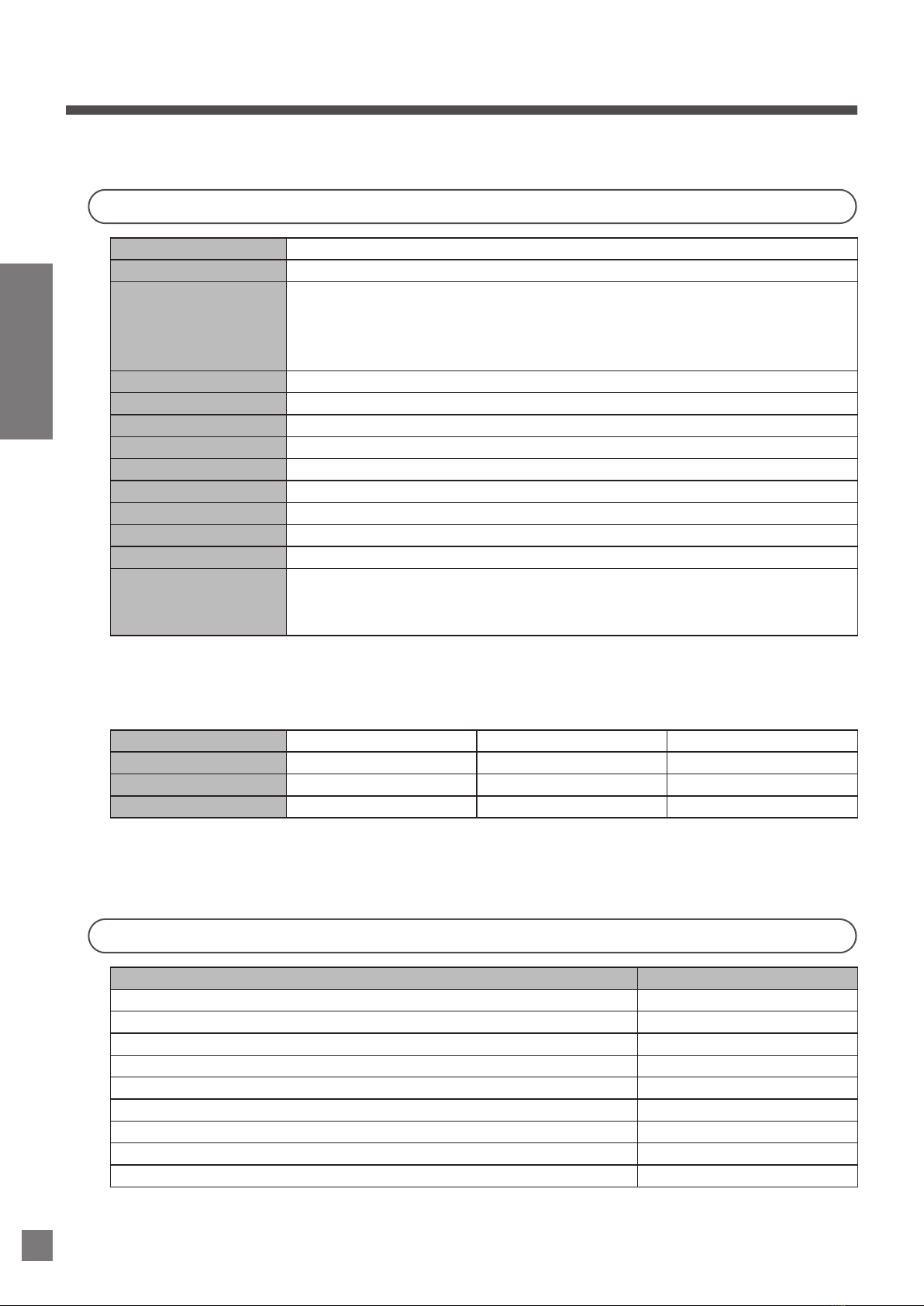

1)EnvironmentofUsage

● All connections between the recovery machine and the cylinder should be disconnected during

transportation.

◆ Allconnectionsbetweentherecoverymachineandthecylindershouldbedisconnected

duringtransportation.

◆ Steerclearofinjurieswhenyoucarryaheavycylinder.

2)Transportation

CAUTION