ASAHI 19 Series User manual

Need more information? Download a complete IOM at our website. www.asahi-america.com

File: Series 19 SMART Modulating Failsafe User Manual Rev B 3/14/2022 Page 1 of 5

Series 19 SMART Modulating Failsafe Electric Actuator User

Manual

Description

The Series 19 smart modulating electric actuator features a reversing motor with multi-

voltage capabilities, 95 VAC to 265 VAC (50/60 Hz) or 24 VAC/VDC, an OLED screen,

an internal heater, positioner, transmitter, alarm/fault contacts, a NEMA Type 4X

enclosure, manual override, visual beacon position indication, LED fault indicator (blue),

ISO mounting, and flying leads. The alarm/fault contacts are SPST and rated for 0.1

Amp @ 250 VAC/0.5 Amp @ 30 VDC, and are factory calibrated.

Cover removal is NOT required for installation and will void warranty!!

Additional options are NOT available for this model.

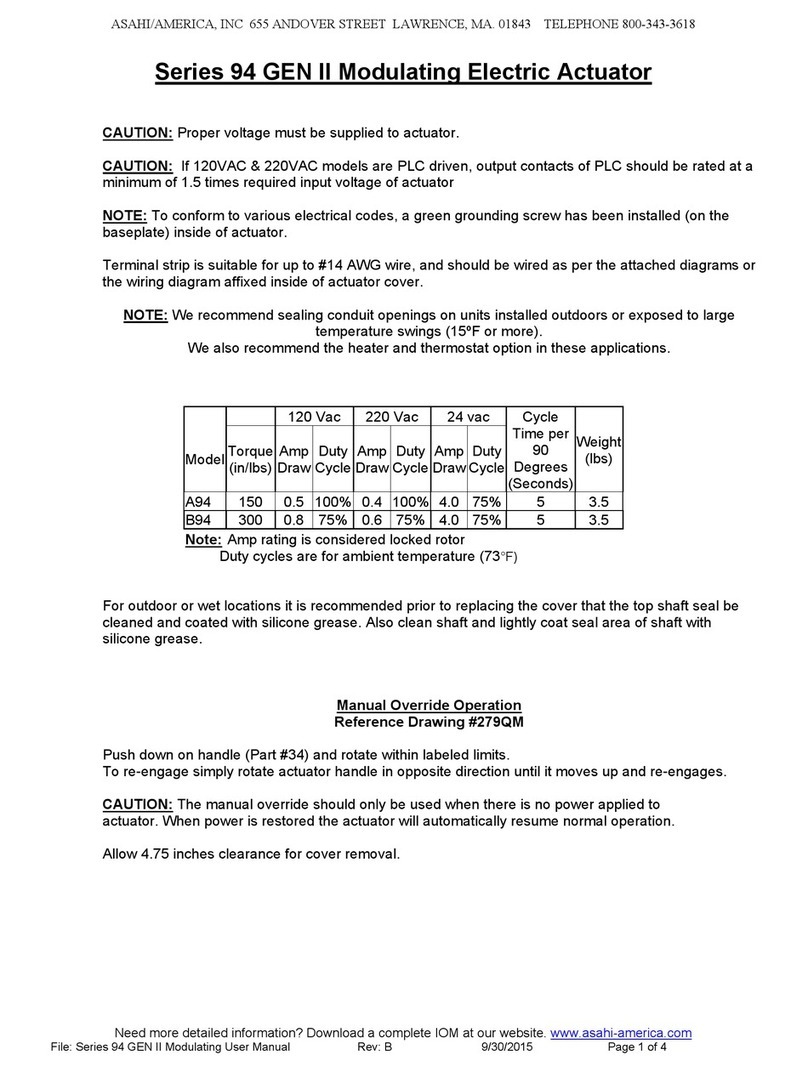

Electrical Requirement

WARNING: Do not open actuator cover as warranty will be void!!

Model Number Torque

(in-lbs)

95

VAC to

265

VAC

24 V

AC

/24

VDC

Cycle Time

per 90

Degrees

(Seconds)

Weight

(Pounds)

Amp

Draw

Duty

Cycle

Amp

Draw

Duty

Cycle

S20C1C3HFSW 177 0.18 75% 0.96 75% 10 seconds 1.7

S50C1C3HFSW 442 0.24 75% 1.20 75% 10 seconds 3.5

S110C1C3HFSW 973 0.90 75% 4.80 75% 10 seconds 4.8

NOTE: Amp rating is considered running.

Duty cycles are for ambient temperature (73° F)

The Series 19 electric actuator has a sealed cable gland with 2 meter flying leads. The

electrician is required to make field connections as per the wiring schematic shown in

this manual for model numbers and voltages listed above. The electrician is responsible

for following all and any, local and/or agency wiring practices.

Note: Not all wires provided will be used.

Need more information? Download a complete IOM at our website. www.asahi-america.com

File: Series 19 SMART Modulating Failsafe User Manual Rev B 3/14/2022 Page 2 of 5

Failsafe ability is disabled for ALL units until capacitor charge reaches 100%. Unit will

function as on/off until capacitor is fully charged. Heater is internally wired and

operational as long as actuator is powered.

Size 20 ONLY

Size 20 is specific to accept only voltage or current as a control signal/loop

Size 20 will be labelled specifically as a voltage or current control signal/loop, and

cannot be changed via onboard firmware. If a different control signal/loop is required,

then another unit with the specific control signal/loop must be used.

Need more information? Download a complete IOM at our website. www.asahi-america.com

File: Series 19 SMART Modulating Failsafe User Manual Rev B 3/14/2022 Page 3 of 5

Size 50 – 110

Size 50 – 110 can be calibrated for EITHER a voltage or a current control

signal/loop via onboard firmware. Please contact the factory for instructions.

Need more information? Download a complete IOM at our website. www.asahi-america.com

File: Series 19 SMART Modulating Failsafe User Manual Rev B 3/14/2022 Page 4 of 5

Manual Override Operation

Remove manual override hex key from storage position located on the bottom of

actuator, which is secured by stainless steel clips. To operate the manual override,

insert hex key into hex socket located on top of actuator and rotate to manually cycle

valve (CCW to open, CW to close). When finished using the manual override, it is

imperative to remove the hex key and place it back into storage on actuator base,

making sure that it “clicks” into the locking position.

CAUTION: The manual override should only be used when there is no power applied to

actuator. When power is restored, the actuator will automatically resume normal

operation.

Local Controls Operation

The actuator can be locally controlled and driven to the open or closed position via

OLED screen and push buttons. This simple procedure is detailed below.

Press and hold the “↕” button for 3 seconds. “K3” will flash in the top right hand corner

and the unit will ask for a password. At this time, the password of “111” can be entered

with “↕” selecting numbers and “↔” selecting the field. Once password is entered, press

the “M” button to enter manual mode. The actuator can now be opened and closed via

the push buttons. Press the “↨” button to OPEN the actuator. Press the “↔” button to

CLOSE the actuator. To exit manual mode, press the M button or wait approximately

120 seconds and the manual mode will time out and exit. The actuator will not respond

to control signals from the PLC until taken out of manual mode.

Troubleshooting

Actuator does not respond

Power not connected Connect power

Voltage below level or incorrect Confirm correct voltage

Torque limiter tripped

Power unit in opposite direction, then

power to original position to confirm a

tripped torque limiter

Loose/poor termination Confirm proper termination

Need more information? Download a complete IOM at our website. www.asahi-america.com

File: Series 19 SMART Modulating Failsafe User Manual Rev B 3/14/2022 Page 5 of 5

Troubleshooting Continued

Actuator does not respond

Incorrect signal provided to actuator

Verify that control signal from PLC

matches control signal of actuator. *Size

20 is provided as ONLY accepting a mA

signal or ONLY accepting a current control

signal

Crossed signal wiring

Confirm that control signal wiring is

terminated at the appropriate wiring

location of actuator (0-10 VDC signal

connected to 4-20 mA actuator wiring, as

an example)

Series 19 ISO 5211 Output

Series 19 Envelope Dimensions

This manual suits for next models

3

Table of contents

Other ASAHI Controllers manuals