Inspect before using the pulley.

Using the product when there is a problem accelerates the

damage and may lead to strength deterioration, damage

to the product, or an accident of falling hoisted load.

Inspection and maintenance

In case of trouble

Remove the nut using a socket wrench.

* Use adhesive agent that is sticky.

(Loctite 271 is recommended)

When detaching the nut, and then attaching the nut again, apply

adhesive agent to the screw of the nut.

●The sheave pin and the becket bolt are subject to the caulking

operation to prevent looseness.

Socket

Swivel

Body

Sheave pin ●Sheave pin

Sheave

●Sheave

●Sheave pin

●Becket pin

●Becket

●Caulking jig

●Becket

●Sheave

●Sheave pin ●Sheave

Bearing

Nut

Sheave pin

Sheave pin nut

Becket bolt

Caulking jig

(Sold separately)

Hexagon socket wrench

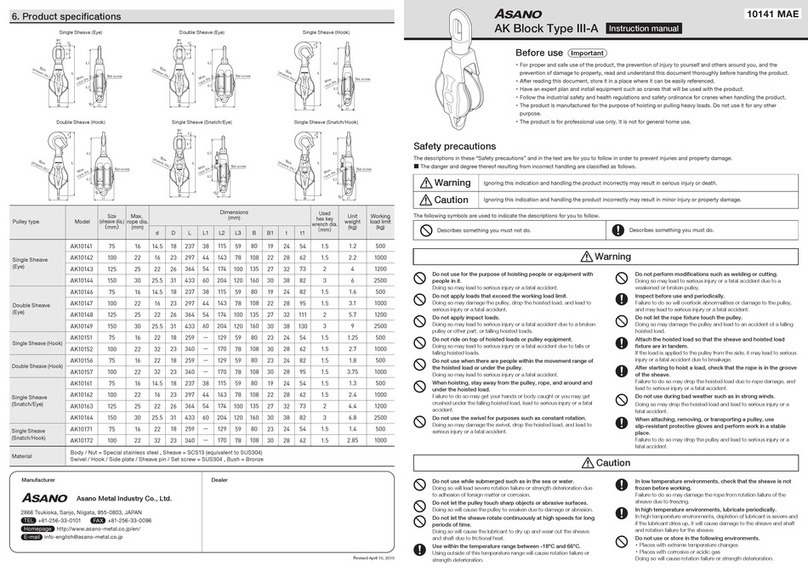

Size 50 75 100

Double face

width of nut

14mm 22mm 24mm

[Replacement parts]

Inspection before use

Warning

In the unlikely event the pulley deforms or breaks and

a load is hanging in midair, first take down the hoisted

load, unload the pulley, and take safety measures to

prevent secondary disaster.

Warning

Do not use products that are in the following conditions.

·Products that are deformed, cracked, or worn out

·Products with signs of corrosion such as rust

stains or galvanic corrosion

Doing so may lead to serious injury or a fatal accident

due to falls or falling hoisted loads.

Do not let the product touch other types of metal

for long periods of time.

Doing so will cause corrosion.

Warning

Be sure to apply adhesive agent.

If adhesive agent is not applied, the nut will come

off and the sheave will fall, leading to accident.

Warning

Do not scrape the body.

Since the body becomes unusable when it is

scraped, do not scrape any more once the

caulking part of the becket bolt is removed.

Caution

Be sure to perform caulking operation. Also be

sure to check that the nut does not become

loose after performing caulking operation.

If not fully caulked, the nut will come off and the

sheave will fall and lead to accident.

Warning

Be sure to perform caulking operation. Also be

sure to check that the nut and bolt do not become

loose after performing caulking operation.

If not fully caulked, the nut or bolt will come off

and the sheave will fall, leading to accident.

Warning

Caution

Caution

●The sheave pin nut and the becket pin nut are subject to the caulking

operation to prevent looseness.

<Inspection of movable parts>

<Nut inspection>

●The swivel and sheave rotate smoothly.

●Applying to the swivel pin and the side surfaces of the sheave

Sheave

pin nut

Becket pin nut

Disc grinder

Socket

Socket wrench

Remove the caulking part.

Size

50

Double

face width

of nut

Sheave pin nut

13mm

Becket pin nut

10mm

75

18mm

16mm

100

22mm

18mm

Size 125

Socket wrench double

face width

Hexagonal socket wrench

double face width

24mm

8mm

Caution

Wipe frequently.

Attached foreign matter such as sea water, soot, or

iron particles will cause corrosion.

③If the nut is unable to be removed

in ②, scrape the caulking part

with a disc grinder and remove it

with a socket wrench.

* Once removed sheave pin/sheave

pin nut/becket pin/becket pin nut

cannot be reused, so replace them

with new ones.

①Apply anti-seizing agent to the caulking part so that the caulking

will not be seized.

②Remove the sheave pin nut and the becket pin nut with a socket

wrench together with caulking.

③If the nut is unable to be removed

in ②, scrape the caulking part

with a disc grinder and remove it

with a socket wrench.

<Removal>

<Removal>

①Apply anti-seizing agent to the caulking part so that the caulking

will not seize.

②

Remove the sheave pin nut with a socket wrench together with

caulking.

<Attachment>

①Use new sheave pin/sheave pin

nut/becket pin/becket pin nut,

and tighten them with a socket

wrench.

②Caulk so as to expand the tips of

the sheave pin and becket pin. <Attachment>

①Use new sheave pin/sheave pin

nut/becket bolt, and tighten them

with a hexagon wrench or socket

wrench.

②Perform caulking operation so as

to expand the tips of the sheave

pin and the becket bolt.

●Nuts securing the sheave pin are not loose or defective.

*For the checking method, refer to Removing and attaching the nut.

<Visual inspection of appearance>

<Applying grease (or lubricant)>

<Removing corrosion (rust), dirts, and foreign matter>

●There are no cracks or corrosion in the swivel

and welded part of the swivel pin. There are also

no cracks or corrosion in the other parts.

●There are no bends, twists, distortions, or

stretches.

●There is no excessive wear, denting, or hollowing

out.

●There is no wire scratch marks on the sheave

surface.

●Foreign matter or dirt is not attached.

●Casted characters on the body shall

be readable.

●If a problem occurs while using the pulley, discontinue use immediately,

and check the items in .

①For light dirt (such as hand marks, sand, or mud), wipe with a damp soft cloth or

sponge, and then wipe with a neutral detergent.

②If dirt still remains, wiping with a store-bought cleaner (cleaning solution), remov-

er, or thinner is effective.

③If rust stains (spots of rust caused by iron particles in dirt) remain after perform-

ing ①and ②, use a store-bought rust remover.

④If the rust cannot be removed with a store-bought rust remover, rub it off with

sandpaper or an abrasive compound.

⑤Remove foreign matter by scraping it away with sharp-tipped object such as a

slotted screwdriver, and then perform ①and ②. Rub off persistently attached

foreign matter with a file or abrasive compound because you may damage the

product if you use excessive force.

Do not let grease on the swivel pin dry up.

Drying up will lead to breakage of the swivel pin or

the crack of the welded portion.

Warning

When disassembling the pulley for sheave replacement,

remove it from high places and disassemble on the ground.

Failure to do so may drop the pulley and lead to serious

injury or a fatal accident.

When replacing parts, use ASANO-specied parts.

Failure to do so may result in lower functionality of the

pulley due to incompatible parts.

Warning

Caution

●For inquiries about pulleys, please consult the dealer where you purchased

the product.

●Caulking jig

Sheave

pin nut

Becket

pin nut

Sheave

pin nut

Bearing

Bearing

Becket

Collar

Body

Becket bolt

Sheave

Sheave

Collar

Sheave pin

Sheave pin

Becket pin

Becket bolt

Body

Body

Swivel

Swivel [Replacement parts]

[Sold separately]

[Replacement parts]

[Sold separately]

Double face width

Socket wrench

Socket wrench

Socket

Sheave

pin nut

Disc grinder

Remove

caulking

⑤

If the becket bolt is unable to be

removed in ④, scrape the caulking

part with a drill (ø11mm) and remove

it with a hexagon socket wrench.

* Once removed sheave pin/sheave pin nut/becket bolt cannot be

reused, so replace them with new ones.

Drill (ø11)

Swivel

Sheave

Swivel Sheave

Sheave pin

Body Swivel pin

Caulking

Pin

Nut

Caulking jig

(Sold separately)

Caulking

Anti-seizing

agent

Anti-seizing

agent

Caulking

Becket bolt

Inspection and maintenance

AK Block Type PB, Single Sheave (Size 50, 75, 100)

AK Block Type PB, Double Sheaves (Size 50, 75, 100)

AK Block Type PB-II (Size 125)

■Part names

■Part names

■Part names

■Removing and attaching the nut

■Removing and attaching the nut

■Removing and attaching the nut

Adhesive

agent

Maintenance

Periodic inspection

④Remove the becket bolt with a hexagon socket wrench together

with caulking.

Grease

Elongation

Welded part of

the swivel pin

Anti-seizing

agent

If rotation is poor, not

centered, significantly

rattles, or if rotation

stops, discontinue use

and replace the part or

product.

Apply grease to the gap of the

swivel pin in the inner side of the

body to prevent the rotation

failure and abrasion of the swivel.

In order to prevent water invasion

into the bearing, apply grease to the

bearings on the side of the sheave.

●Perform periodic inspection at least once a year.

●If you use the product under harsh conditions such as frequent hoisting of

loads equal to the working load limit, impact loads, or intense rolling, perform

inspection more frequently because the parts will wear out substantially.

●For periodic inspection, inspect all of the items in ,

perform , and check the dimensions of each part. If the

dimensions are 10% different from the original dimensions or the dimensions

in the catalog, replace the part or product.

(Refer to for the dimensions.)

Inspection before use

Maintenance

Product specifications