ASG, Division of Jergens, Inc.

15

7

0

0

S. Waterloo Road | Cleveland, OH 44110-3898 | Phone: (888) 486-6163 | Fax: (216) 481-4519 | Email: [email protected] | Web: www.asg-jergens.comImportant: Please read and save the operang instrucons.

Warning: When using electric tools, the following basic safety pre-

cauons should always be adhered to in order to reduce the risk of

re, electric shock, or personal injury.

Precauons

1. Keep Work Area Clean: Cluered areas and benches can result

in injuries.

2. Consider Work Area Environment: Do not expose tools to rain.

Do not use tools in damp or wet locaons. Keep work area

well lit. Never use the tool in an area with dangerous objects

present. (gasoline, benzene, thinner, gas glue, metallic objects,

etc.)

3. Secure Work: Use clamps or a vice to hold work piece.

4. Guard Against Electric Shock: Prevent body contact with

grounded surfaces.

5. Keep Away From Children and Unauthorized Personnel: Do not

allow children or unauthorized personnel to use the tool.

6. Store Idle Tools: When not in use, tools should be stored in a

dry and high or locked-up place.

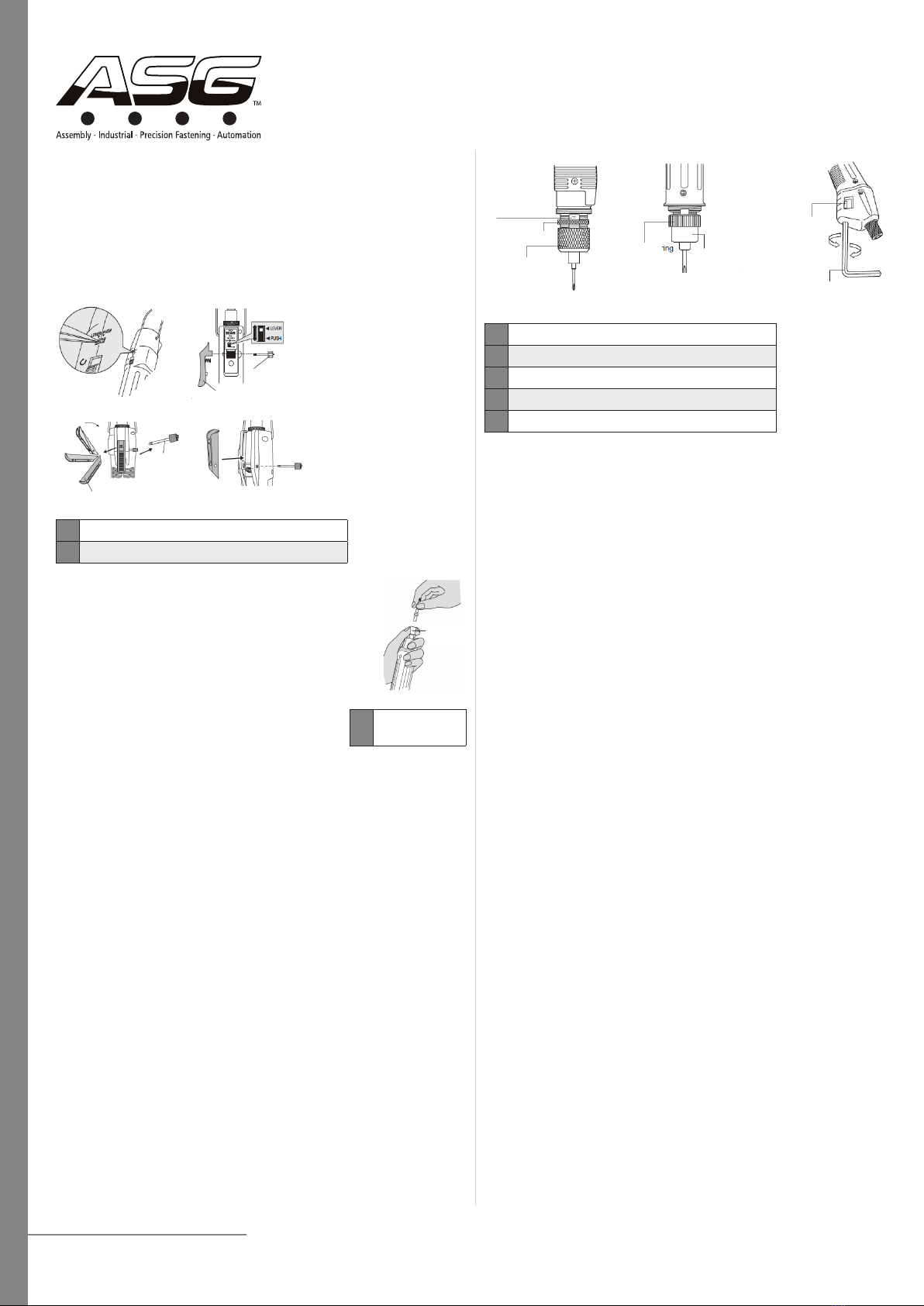

7. Remove Adjusng Keys And Wrenches: Make a habit of

checking to see that keys and adjusng wrenches are removed

from the tool before turning it on.

8. Use The Correct Tool: Use the tool for the correct work for its

rated power and design.

9. Dress Properly: Do not wear loose clothing or jewelry as they

can be caught in moving parts. Wear protecve head wear to

contain long hair.

10. Use Safety Glasses: Also use a face or dust mask if the operaon

involves dust.

11. Do Not Abuse The Cord: Never carry the tool by its cord or pull

it to disconnect from the power outlet. Keep the cord away

from heat, oil, and sharp edges.

12. Do Not Overreach: Maintain proper foong and balance at all

mes.

13. Maintain Tools With Care: Keep tools clean for beer and

safer performance. Follow instrucons for lubricang and

changing accessories. To use the tool for an extended period

of me safely, perform periodical inspecons on the tool and

if damaged, contact ASG. Keep hands dry, clean, and free from

oil and grease. Inspect extension cords periodically and replace

if damaged.

14. Disconnect Tools: When the tool is not in use, such as aaching

and removing the bit, changing the Carbon Brush, inspecon

or cleaning, disconnect the tool from the power outlet.

15. Avoid Unintenonal Starng: Ensure that the switch is o when

plugging in. Do not carry the tool with nger on the switch.

16. Stay Alert: Always remain vigilant, use common sense, and do

not operate the tool when you are red.

17. Check Damaged Parts: Before using the tool, a damaged

protecve cover or other parts should be carefully checked to

determine whether the tool will operate correctly and perform

as designed.

18. Ground the tool.

19. It only takes a slight amount of pressure for a push-to-start tool

to go into operaon.

Cauons in Operaon

1. If there are any problems, do not disassemble the tool. Stop

operaons and contact ASG immediately.

2. Never lubricate the tool with aerosol oil or similar lubricants.

3. Do not drop, hit, or abuse the tool.

4. Never use chemicals to wipe the body cover

5. Use only the correct voltage.

6. Do not pull the AC cord when unplugging from the power

outlet. Grasp the plug.

7. For safety use, do not set the torque adjusng nut higher than

10 on the torque adjusng scale

8. Use the tool intermiently: (Example: 0.5 seconds ON, 4.5

seconds OFF)

9. Do not ghten more than 720 tapping screws in an hour.

10. This tool is not for ghtening wood screws

11. Set the power switch to OFF before pung the tool in reverse.

12. If the tool is not being used, turn the tool o and unplug the

AC cord plug.

13. In push-to-start mode the driver automacally goes on when

pressure is applied to the bit end.

14. In push-to-start mode do not raise the driver from the screw

head unl rotaon has stopped

Grounding Instrucons

The tool should be grounded while in use to protect the operator

from electric shock.

Operang Procedure

1. Use the torque adjustment nut to select the desired output

seng.

2. Aach the bit to the screwdriver

3. Turn the FOR/REV switch to OFF and connect the driver plug

to an AC power outlet.

4. Turn the switch to either FOR or REV to start the screwdriver.

5. Operate the clutch unl the screw is ghtened to the set

torque value.

6. Always turn the power o before reversing the rotaon

direcon seng.

7. When loosening a ghtened screw, turn the FOR/REV switch

to REV and loosen in the reverse direcon.

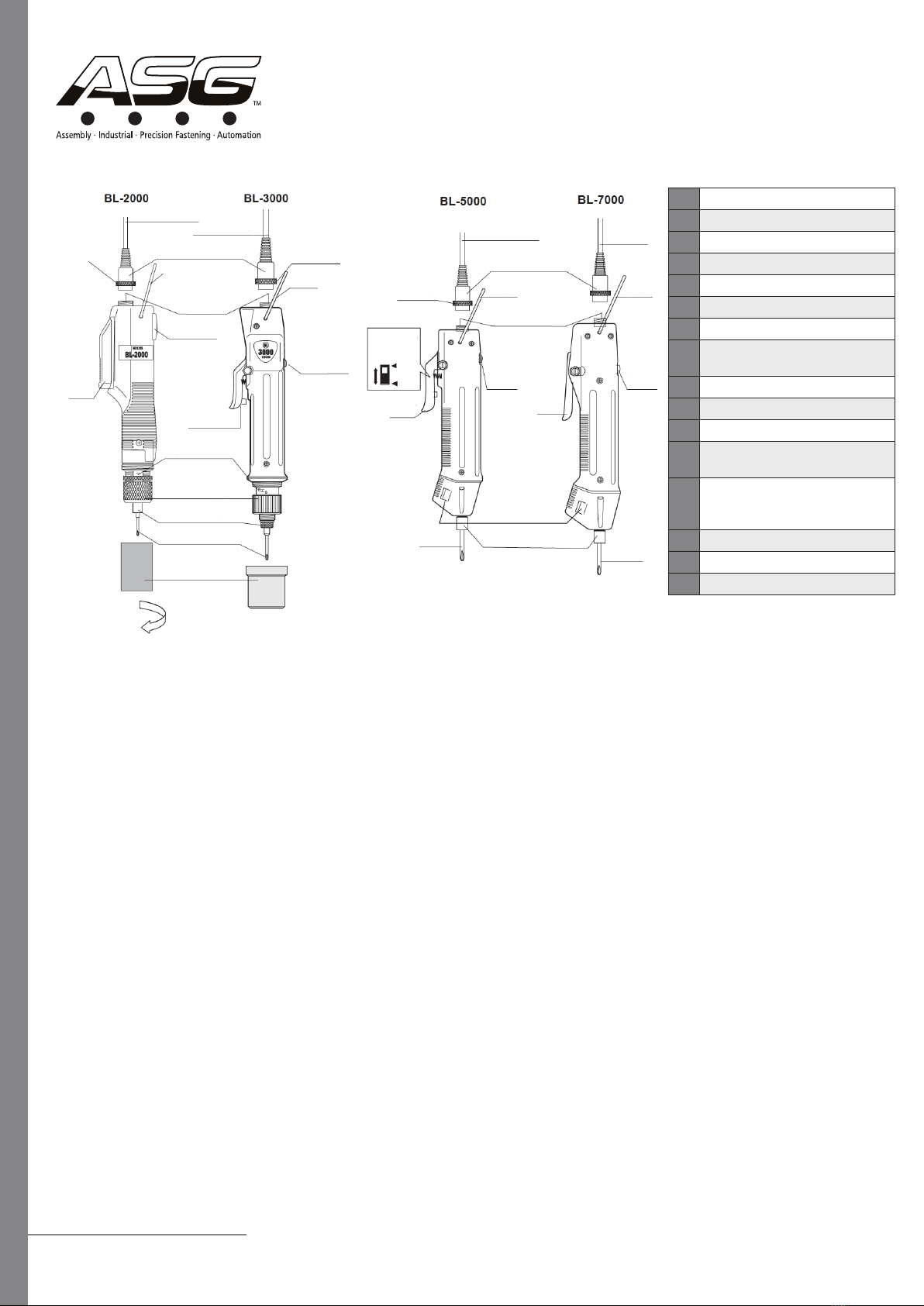

HIOS BL Series

Operaonal Manual