ASGCO Mfg., Inc. 3 CHEVRON

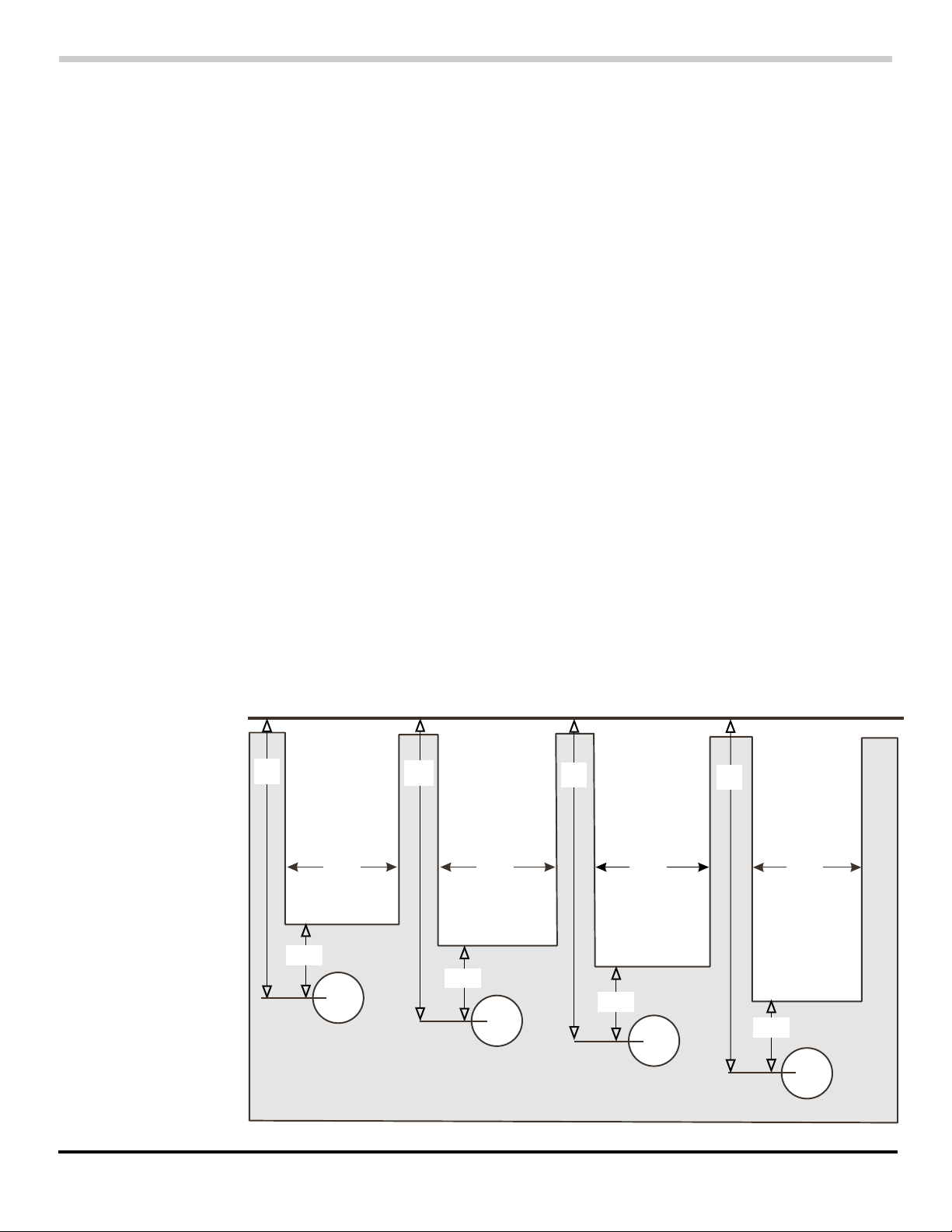

Disc Four Three Shaft Two Shaft

Diameter Assembly Assembly Assembly

10” 57” 43” 29”

8” 50” 38” 26”

6” 43” 33” 23”

NOTE: The center point of the last shaft must be at least 10" away from any

pulley or idler that is mounted below the belt.

It is also important that the mounting location is adequate to allow the

scraped material to fall back into the main discharge chute or a dribble

chute. To ensure sufficient flow of the scraped material down the chute, an

unlined chute should have at least a 75° angle (to the horizontal); and

UHMW plastic lined chute should have at least a 65° angle (to the

horizontal).

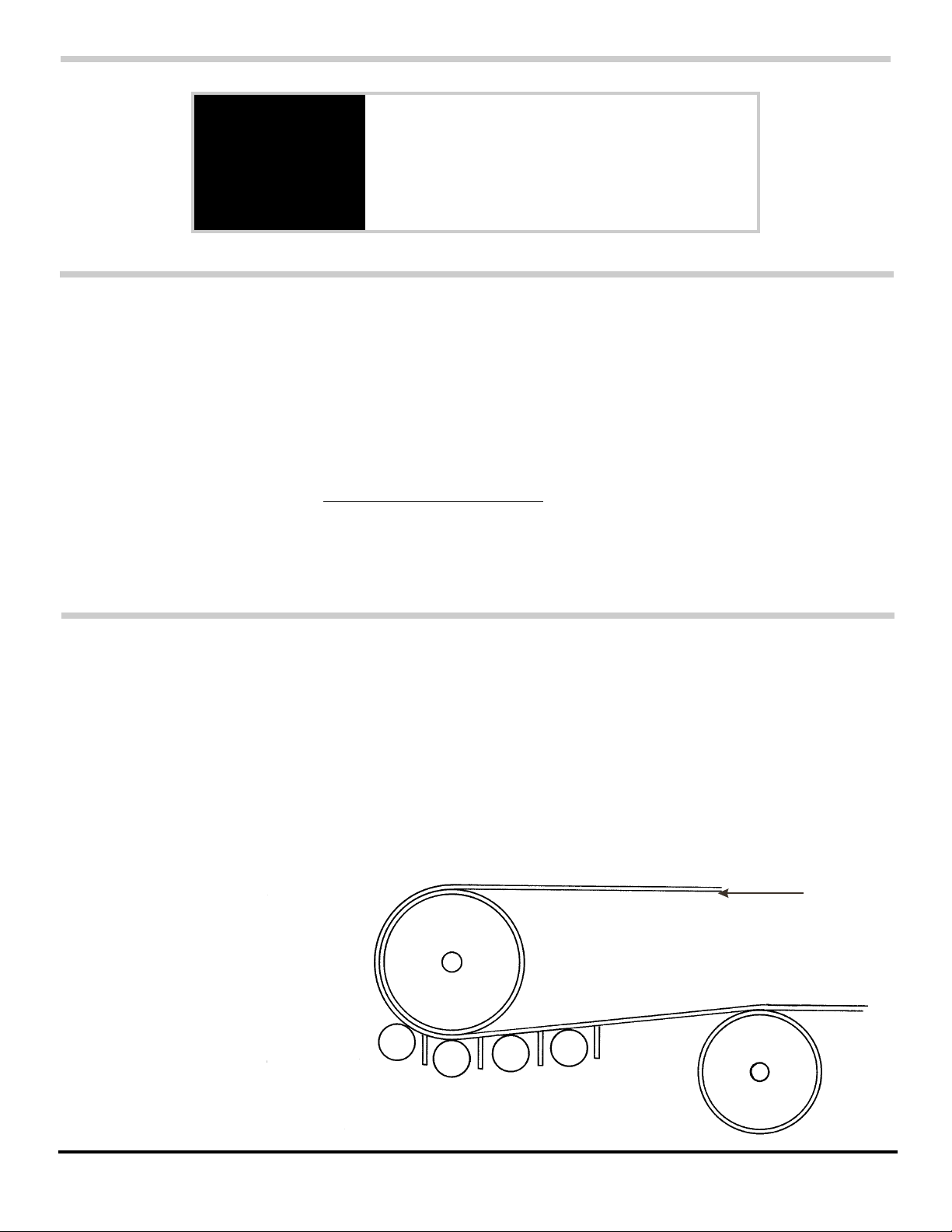

BELT TENSION REQUIREMENTS - Because of the unique design of the

Chevron, the shafts must be mounted in a flat, tight area of the belt. The

Chevron cannot operate to its maximum effectiveness on a belt that is

loose or bowed.

ADDING IDLERS OR PULLEYS - If a sufficient mounting location cannot

be found between the head and snub pulleys, the Chevron can be located

elsewhere, provided that the proper steps have been taken to prevent the

belt from loosening or troughing in the contact area. This can be done by

mounting standard return idlers or small pulleys above the belt.

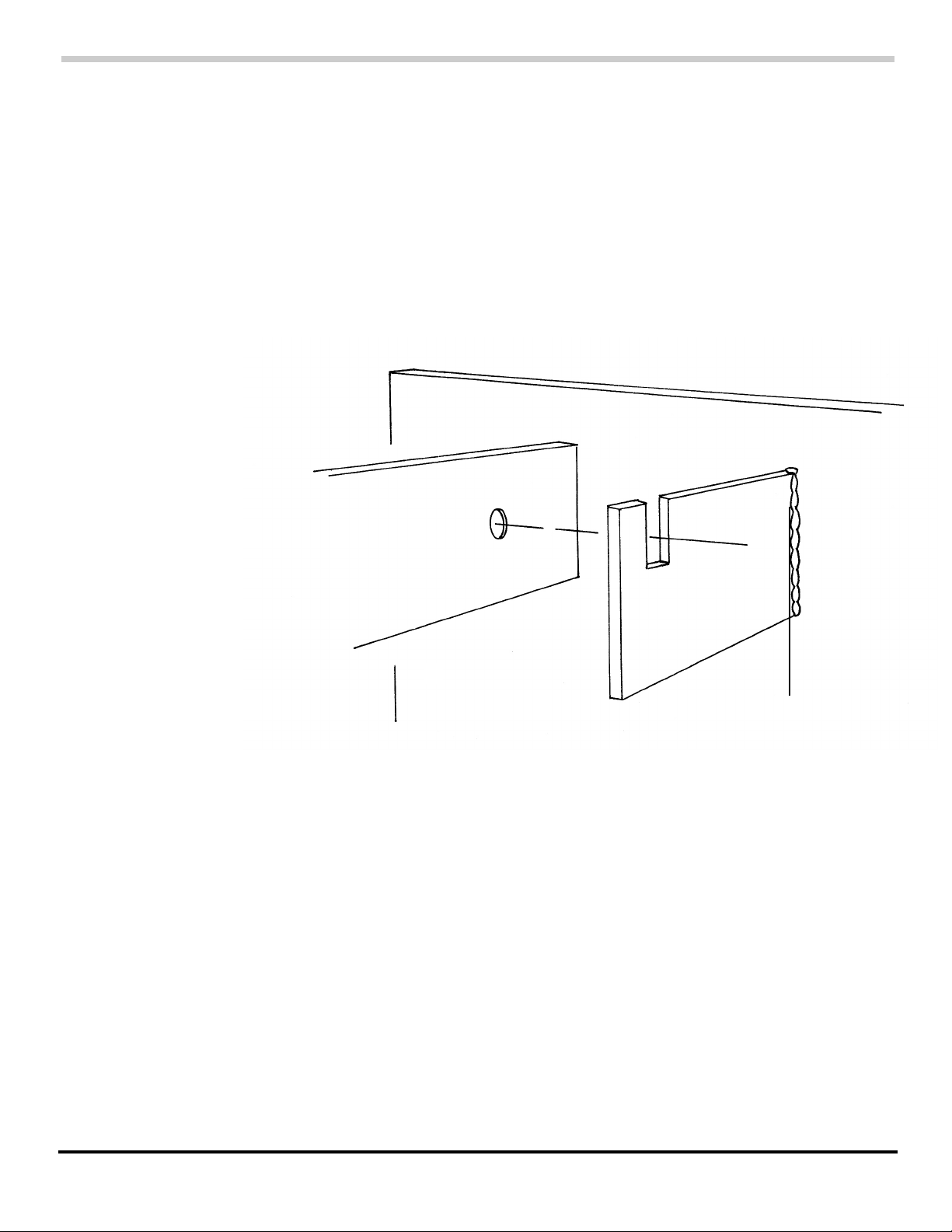

FABRICATING MOUNTING PLATES - If a chute is not present in the

desired mounting location, mounting plates can be fabricated to simulate

the sides of the chute and provide a mounting base for the Chevron shafts.

These plates are made from 1/4" to 3/8” flat stock steel and should

measure 12" to 16" high. Extend the plates the length of the Chevron

installation, with an extra 6" on each end.

Once a suitable mounting location has been chosen, the initial setup work

can begin. Proceed as follows:

1. The first measurement will vary, depending on the disc diameter and

the size of the bearings within the pillow blocks:

A. IF USING 6" DISCS WITH I " BEARINGS, measure the distance to a

point 6" down from (perpendicular to) the belt on the chute wall.

Mark this point "X'.

B. IF USING 8" DISCS WITH 1 " BEARINGS, measure the distance to a

point 61/2" down from (perpendicular to) the belt on the chute wall.

Mark this point "X".

C. IF USING 8" DISCS WITH 13/8" OR 1 1/2" BEARINGS, measure the

distance to a point 7" down from (perpendicular to) the belt on the

chute wall. Mark this point "X'.

Initial

Setup