www.ashlandind.com

3

PH: 715-682-4622

Introduction

Thank you for choosing an Ashland disc harrow for your earth tilling needs.

Years of research, testing, and successful application have been spent to

ensure quality and maximum performance for our customers.

Quality Policy

It is our mission to exceed our customers’ expectations in quality, delivery, and cost

through continuous improvement and customer interaction.

Please read and understand this manual before attempting to attach or operate this

disc harrow. This manual should always remain with the machine. Be sure and fill out

and send in the owner’s registration form at the beginning of this manual, or you may

fill out the form on-line by going to ashlandind.com and click on “Owner Registration”

in the Support section drop-down. If you have questions, please feel free to call or

email us. You can visit us on-line at www.ashlandind.com.

Ashland Industries hours of operation are 8:00 a.m. to 5:00 p.m. CST. We can be

reached toll free at: 877-634-4622.

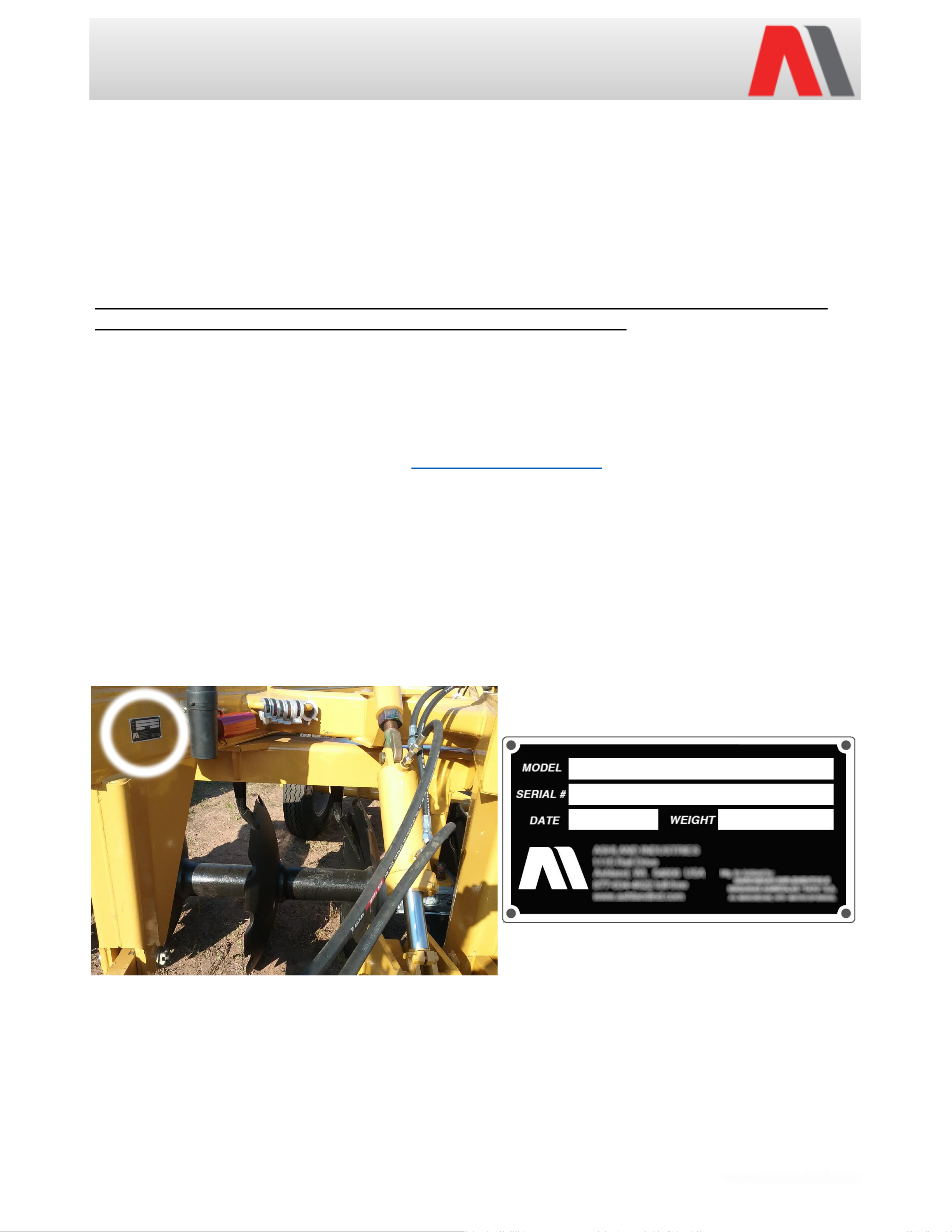

ID Number

You can find the serial number plate for most machines on the front section of the

frame along in the inner tube. The letter and numbers stamped identify the serial

number, model number, weight, and date of manufacture. Please record this serial

number for use in ordering parts, warranty issues, and to track your equipment if it is

ever stolen.

Important

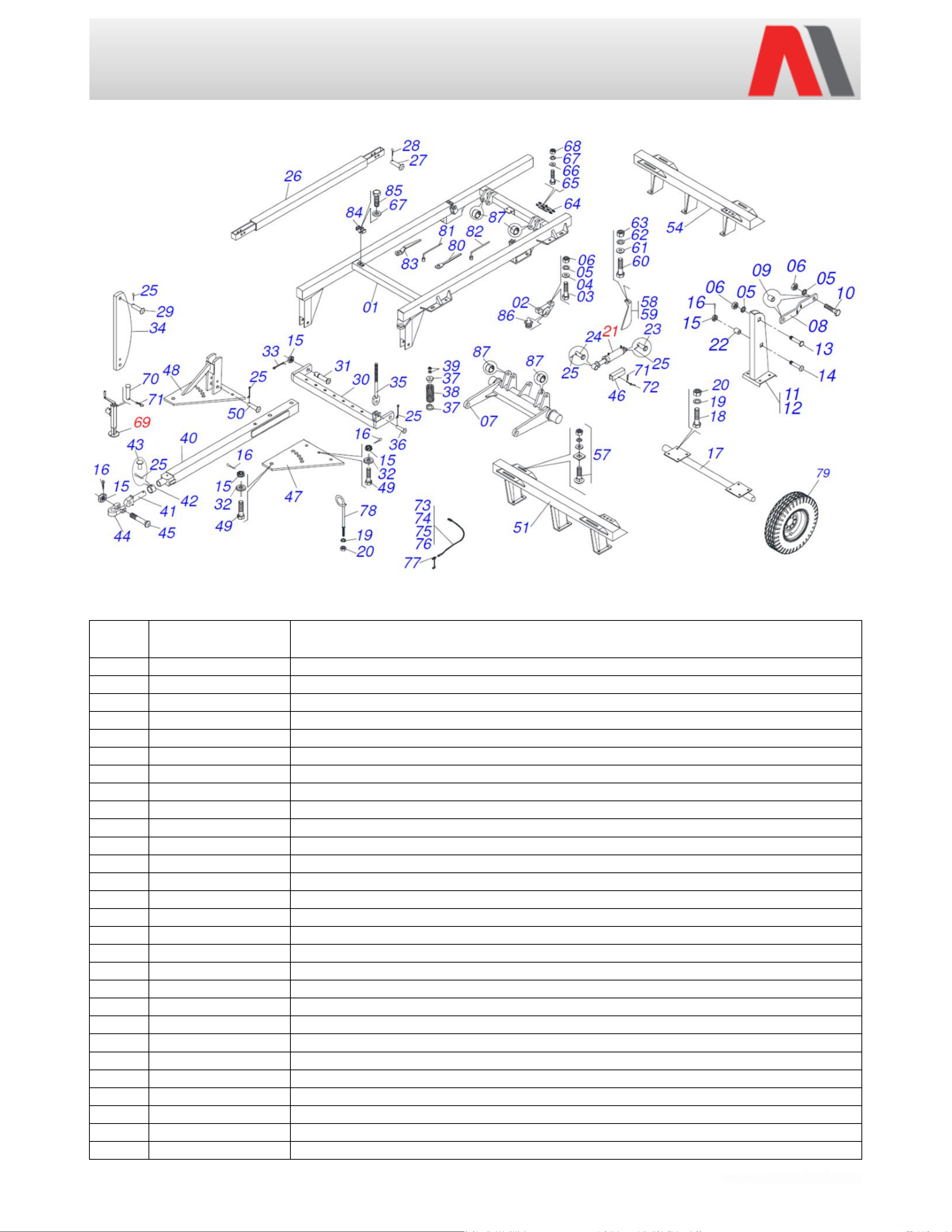

Parts must be ordered through your local authorized ASHLAND dealer. Be sure to

state MODEL and SERIAL NUMBER of your machine. Ashland Industries Weldable

replacement parts are also available to rebuild, modify, or update your machine to

current factory specifications.